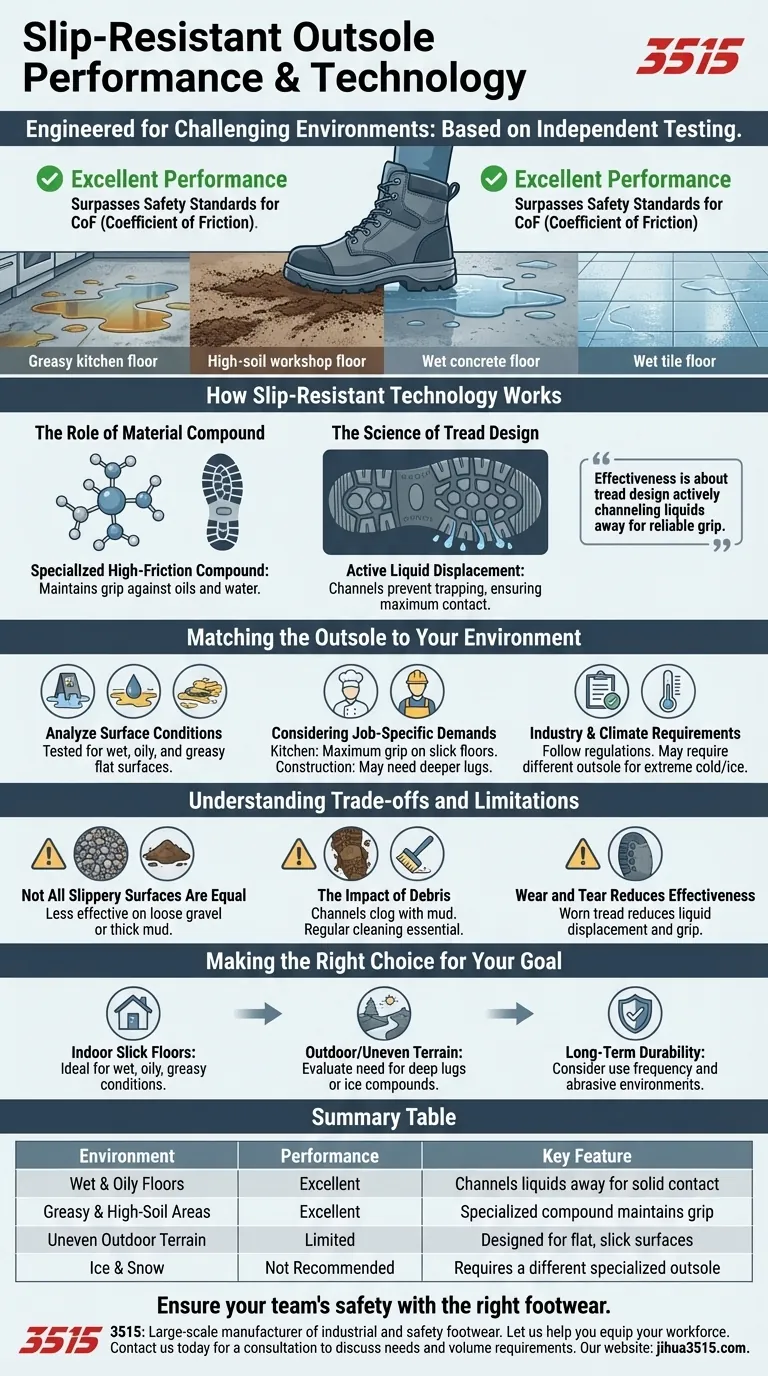

Based on independent testing, this slip-resistant outsole performs exceptionally well across a range of challenging environments. It has been proven to surpass the required safety standards for Coefficient of Friction (CoF) on greasy, high soil, oily/wet, and standard wet surfaces, ensuring secure footing where it matters most.

The effectiveness of a slip-resistant outsole is not just about the material, but how its tread design actively channels liquids away from the point of contact. This deliberate engineering is what creates a reliable grip on otherwise hazardous surfaces.

How Slip-Resistant Technology Works

To understand its performance, you must first understand the core principles that provide its grip. The outsole relies on a combination of specialized materials and intelligent geometric design.

The Role of Material Compound

The foundation of the outsole is a specialized material engineered for a high degree of friction. Unlike standard rubber, this compound is formulated to maintain its gripping properties even when interacting with oils and water.

The Science of Tread Design

The physical pattern of the outsole tread is critical. Shapes like hexagons or circles create a network of channels that prevent liquids from being trapped underfoot.

This design allows water, oil, and other fluids to displace instantly, ensuring the sole makes maximum contact with the solid floor surface for a better grip.

Matching the Outsole to Your Environment

A shoe's performance is only as good as its suitability for the specific conditions you face. Assessing your environment is a critical step in ensuring safety.

Analyzing Surface Conditions

The primary strength of this outsole is on flat surfaces contaminated with liquids. It is specifically tested for wet floors, oily surfaces, and greasy areas common in kitchens, workshops, and industrial settings.

Considering Job-Specific Demands

Different roles have different needs. A kitchen worker requires maximum grip on slick, level floors, whereas a construction worker may need deeper lugs for uneven terrain in addition to slip resistance.

Industry and Climate Requirements

Always consider your specific industry's safety standards or regulations. Furthermore, while excellent on wet surfaces, performance in extreme cold, ice, or snow may require a different type of specialized outsole.

Understanding the Trade-offs and Limitations

No single outsole is perfect for every possible scenario. True expertise comes from understanding the boundaries of the technology.

Not All Slippery Surfaces Are Equal

An outsole optimized with fine channels for displacing oil on a smooth floor may be less effective on loose gravel or thick mud. The design is highly specialized for its intended purpose.

The Impact of Debris

The channels designed to clear away liquids can become clogged with thick mud or high soil. Regular cleaning is essential to maintain the outsole's peak slip-resistant performance.

Wear and Tear Reduces Effectiveness

Over time, the tread pattern will naturally wear down. As the channels become shallower, the outsole’s ability to displace liquid decreases, which will gradually reduce its grip.

Making the Right Choice for Your Goal

Use these guidelines to determine if this outsole aligns with your safety needs.

- If your primary focus is indoor safety on slick floors: This outsole is an ideal choice, as its design is specifically engineered for wet, oily, and greasy conditions found in kitchens or garages.

- If your primary focus is on outdoor or uneven terrain: You should evaluate whether you also need features like deep lugs for mud or specialized compounds for ice, which this design may not prioritize.

- If your primary focus is long-term durability in a high-use role: Consider the frequency of use and the abrasive nature of your environment, as tread wear is the primary factor in the outsole's long-term effectiveness.

Ultimately, choosing the right outsole is a foundational step in ensuring your safety at work.

Summary Table:

| Environment | Performance | Key Feature |

|---|---|---|

| Wet & Oily Floors | Excellent | Channels liquids away for solid contact |

| Greasy & High-Soil Areas | Excellent | Specialized compound maintains grip |

| Uneven Outdoor Terrain | Limited | Designed for flat, slick surfaces |

| Ice & Snow | Not Recommended | Requires a different specialized outsole |

Ensure your team's safety with the right footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial and safety footwear for distributors, brand owners, and bulk clients. Our slip-resistant outsoles are engineered for superior performance in demanding environments.

Let us help you equip your workforce with reliable, high-quality safety shoes.

Contact us today for a consultation to discuss your specific needs and volume requirements.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments