In essence, the refurbishment service for Goodyear Welted shoes is a comprehensive reconstruction process. It involves completely removing the worn-out sole, cork footbed, and heel block, then rebuilding the shoe's foundation on its original last, all while preserving the original leather upper that has molded to your foot.

Refurbishment is not a simple repair; it is a full reconstruction of the shoe's foundation. This process leverages the unique Goodyear welt construction, which separates the sole from the upper, to grant the footwear a second, third, or even fourth life.

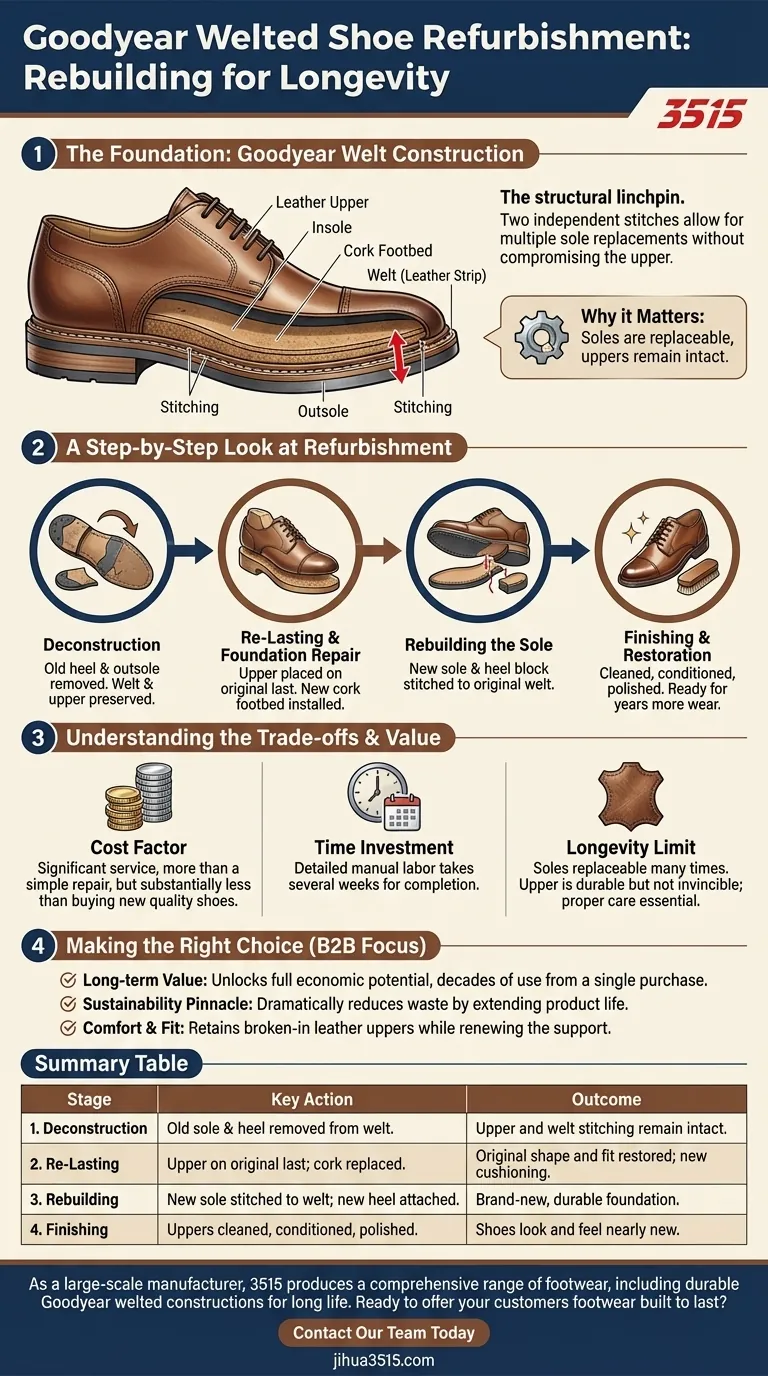

The Foundation: Understanding the Goodyear Welt

To appreciate the refurbishment process, you must first understand the construction that makes it possible. The Goodyear welt is the structural linchpin of high-quality, long-lasting footwear.

What is a Welt?

A welt is a dedicated strip of leather that runs along the perimeter of the outsole. Its sole purpose is to act as an intermediary, connecting the shoe's upper to the sole.

The Stitching That Changes Everything

In a Goodyear welted shoe, there are two independent stitches. The first stitch attaches the leather upper to the welt. The second, separate stitch attaches the welt to the outsole.

Why This Matters for Longevity

This two-level stitching system is the key. Because the stitch holding the sole in place never punctures the upper, the sole can be removed and replaced multiple times without ever compromising the shoe's main structure.

A Step-by-Step Look at the Refurbishment Process

When you send your shoes to a manufacturer or skilled cobbler for refurbishment, they undergo a meticulous, multi-stage process that closely mirrors their original creation.

Stage 1: Deconstruction

First, the skilled craftsperson carefully removes the old heel and worn-out outsole. This process detaches the sole from the welt, leaving the upper and its original stitching intact.

Stage 2: Re-Lasting and Foundation Repair

The shoe's upper is then placed back onto its original last—the wooden form used to give the shoe its shape. This is critical for restoring the shoe's intended structure and fit. The old cork filling, which provides cushioning and molds to your foot, is also removed and replaced.

Stage 3: Rebuilding the Sole

A brand-new leather or rubber sole is precisely stitched onto the original welt. A new heel block is then attached, creating a completely new foundation for the shoe.

Stage 4: Finishing and Restoration

Finally, the shoes are cleaned, conditioned, and polished. The leather uppers are revitalized, and the new sole edges are trimmed and finished, often making the shoe look nearly new.

Understanding the Trade-offs

While refurbishment is an excellent service, it's important to approach it with a clear understanding of the practical considerations.

The Cost Factor

A full factory refurbishment is a significant service, not a minor repair. The cost is considerably more than a simple reheel, but it is substantially less than buying a new pair of shoes of the same quality.

The Time Investment

This is not an overnight process. Due to the detailed, manual labor involved, a full refurbishment can take several weeks from the time you send your shoes in to when you receive them back.

The Limit of Longevity

While the sole can be replaced many times, the upper is not invincible. Eventually, after decades of wear, the leather itself may crack, tear, or wear out. Proper care, including regular cleaning and conditioning, is essential to maximize the lifespan of the upper.

Making the Right Choice for Your Investment

Deciding to refurbish is about embracing a different philosophy of ownership—one focused on longevity and value over disposability.

- If your primary focus is long-term value: Refurbishment is the key to unlocking the full economic potential of your Goodyear welted shoes, turning a single purchase into decades of use.

- If your primary focus is sustainability: This process is the pinnacle of sustainable footwear, dramatically reducing waste by extending a single product's life far beyond that of its cemented counterparts.

- If your primary focus is comfort: Refurbishment allows you to keep the perfectly broken-in leather uppers that have molded to your feet while completely renewing the sole and support structure.

Ultimately, investing in Goodyear welted footwear and its refurbishment cycle is an investment in quality that is designed to last.

Summary Table:

| Stage | Key Action | Outcome |

|---|---|---|

| 1. Deconstruction | Old sole & heel are carefully removed from the welt. | Upper and welt stitching remain perfectly intact. |

| 2. Re-Lasting | Upper is placed back on its original last; cork is replaced. | Original shape and fit are restored; new cushioning is added. |

| 3. Rebuilding | A new sole is stitched to the original welt; a new heel is attached. | The shoe receives a brand-new, durable foundation. |

| 4. Finishing | Uppers are cleaned, conditioned, and polished; edges are finished. | Shoes look and feel nearly new, ready for years more wear. |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including durable Goodyear welted constructions designed for a long life and multiple refurbishment cycles.

Ready to offer your customers footwear built to last? Let's discuss how our manufacturing expertise can provide the quality and value your business needs.

Contact our team today for a consultation.

Visual Guide

Related Products

- Heavy-Duty Goodyear Welted Pull-On Safety Rigger Boot

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What materials are commonly used in dress shoe construction? A Guide to Quality & Durability

- What are the benefits of Repello Calf suede? Get Water-Resistant Luxury Footwear

- How is comfort ensured in the construction of high-quality shoes? Engineered for All-Day Support

- How often should leather shoes be cleaned and conditioned? A Simple 3-Tier Care System

- What are the key benefits of Goodyear welted shoes? Unlock Decades of Durability & Comfort

- What are spectator shoes and how can they be styled for business casual? Master Subtle Style Statements

- What are the advantages of Blake Stitch construction? Discover Immediate Comfort & Value

- How should a quality dress shoe fit for optimal comfort? A Guide to the Perfect Snug Fit