In short, Blake Stitch construction offers immediate comfort and a more accessible price point. This method directly stitches the outsole to the insole and upper, creating a shoe with significantly more flexibility right out of the box compared to more rigid construction types. Its simpler process also reduces manufacturing costs, making it a popular choice for high-quality dress shoes that don't command the premium of a Goodyear welt.

The core decision to choose Blake Stitch hinges on a trade-off: you are prioritizing initial comfort, a sleek profile, and affordability over the ultimate durability and water resistance found in more complex construction methods.

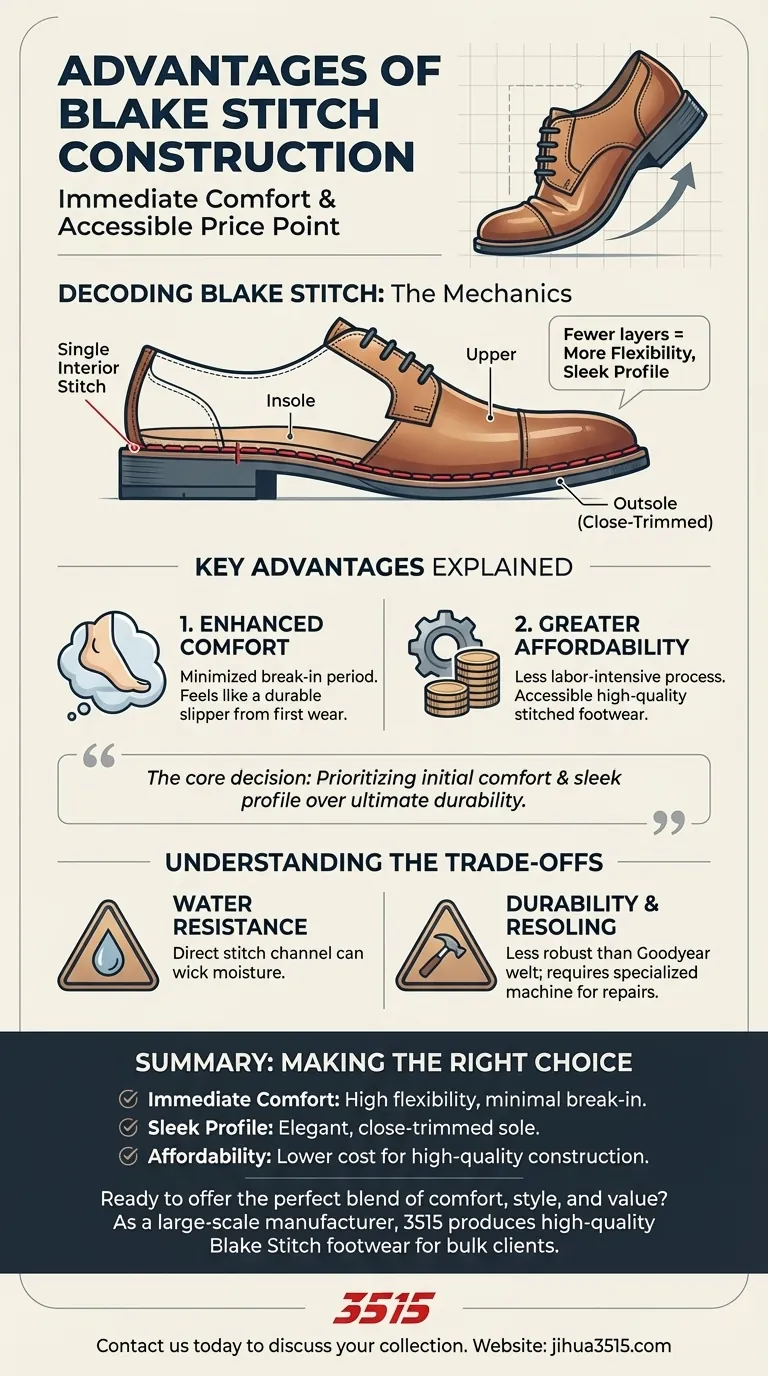

Decoding Blake Stitch Construction

To understand the advantages, you first need to understand the mechanics. Blake Stitching is a method where a single stitch chain-stitches through the outsole, insole, and the shoe's upper.

How It Works

The key is a single interior stitch. This stitch runs from the inside of the shoe, through the insole, then through the upper (which is wrapped around the insole), and finally through the outsole. This single-stitch process is the source of all its primary characteristics.

The Immediate Feeling: Flexibility

Because there are fewer layers between your foot and the sole—no cork filling or extra welt—the shoe can bend and flex with your foot almost immediately. This minimizes the "break-in" period common with more robustly built footwear.

The Visual Cue: A Sleek Profile

This simpler construction allows for a very close-trimmed sole. The sole can be cut very close to the upper, creating a sleek, elegant, and less bulky silhouette. This is why Blake Stitch is common in more formal or fashion-forward Italian-style dress shoes.

Key Advantages Explained

The "why" behind choosing a Blake Stitch shoe comes down to two main benefits that stem directly from its construction method.

Benefit 1: Enhanced Comfort

The reduced number of layers and direct stitching create a shoe that feels more like a durable slipper than a rigid boot. This inherent flexibility provides a level of comfort from the very first wear that is difficult to achieve with other methods.

Benefit 2: Greater Affordability

The Blake Stitch process is less labor-intensive and requires fewer materials than a Goodyear welt. It can be completed quickly with a specialized machine, leading to lower production costs. This cost saving is passed on to the consumer, making Blake Stitched shoes a more accessible entry into high-quality, stitched footwear.

Understanding the Trade-offs

No construction method is perfect, and objectivity requires acknowledging the limitations. The very things that make Blake Stitch advantageous also create its disadvantages.

The Cost of Simplicity: Water Resistance

The single stitch that provides flexibility also creates a direct channel for water. If you step in a puddle, moisture can wick up through the stitch holes and into the insole of the shoe, making them less ideal for consistently wet climates.

The Durability Question

While far more durable than a cemented (glued) shoe, the Blake Stitch is generally considered less robust than a Goodyear welt. The fewer layers and internal stitching can be points of failure over a very long lifespan of heavy wear.

The Challenge of Resoling

Resoling a Blake Stitched shoe is possible, but it is more complicated than with a Goodyear welt. It requires a specific Blake Stitch machine, meaning not every cobbler can perform the service. This can make repairs more expensive or harder to find.

Making the Right Choice for Your Goal

Ultimately, the best construction method depends entirely on your priorities and how you intend to use the footwear.

- If your primary focus is immediate comfort and a sleek look: Blake Stitch is an excellent choice, providing a flexible, ready-to-wear shoe with an elegant profile.

- If your primary focus is all-weather durability and long-term repairability: You may want to consider a Goodyear welt, which offers superior water resistance and easier resoling.

- If your primary focus is budget: Blake Stitch offers a significant step up in quality and durability from glued shoes without the high cost of more complex methods.

Choosing Blake Stitch means selecting a well-crafted shoe that masterfully balances comfort, style, and value.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Immediate Comfort | Minimal break-in period due to high flexibility from direct sole stitching. |

| Sleek Profile | Elegant, close-trimmed sole ideal for formal and fashion-forward styles. |

| Affordability | Lower manufacturing costs make high-quality, stitched footwear more accessible. |

Ready to offer your customers the perfect blend of comfort, style, and value?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including high-quality Blake Stitch constructions that deliver immediate comfort and a competitive price point.

Contact us today to discuss how we can help you build a profitable and stylish footwear collection.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

People Also Ask

- How can one balance a casual outfit when wearing dress shoes? Achieve a Polished Smart Casual Look

- What are the long-term benefits of investing in quality dress shoes? Save Money & Boost Your Style

- How should dress shoes be maintained to prolong their lifespan? A Guide to Lasting Quality

- Why is comfort important in dress shoes? Achieve All-Day Support for Professional Performance

- What should someone do if they are unsure about a company's dress code? Navigate with Confidence