In short, the outer material is a critical factor in a boot's breathability. While a waterproof membrane like GORE-TEX is designed to be breathable, its performance is directly impacted by the material on the outside of the boot. If the outer material becomes saturated with water, it blocks the path for your foot's water vapor (sweat) to escape, effectively suffocating the membrane and trapping moisture inside.

The core issue isn't just the material itself, but how that material behaves when wet. A waterlogged outer fabric creates an impassable barrier for sweat vapor, rendering the boot's internal breathable membrane useless.

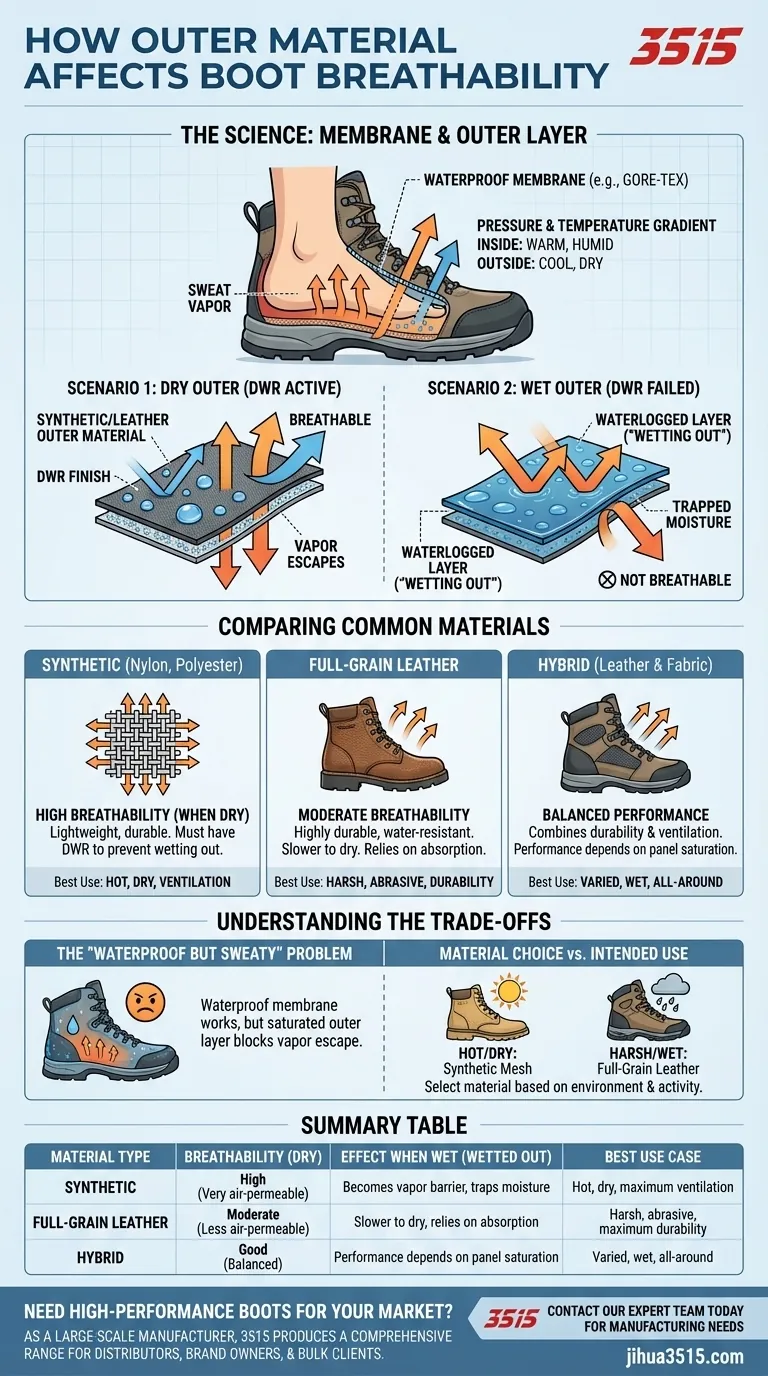

The Science of Boot Breathability

How Breathable Membranes Work

Modern waterproof boots rely on a membrane (like GORE-TEX) filled with microscopic pores. These pores are small enough to block liquid water from entering but large enough to allow individual water vapor molecules (your sweat) to pass through.

This process depends on a pressure and temperature gradient. The warm, high-humidity environment inside your boot naturally pushes moisture vapor towards the cooler, lower-humidity air outside.

The Outer Material's Critical Role

The outer material, or "face fabric," is the boot's first line of defense. It provides durability and structure, but its interaction with water is what makes or breaks breathability.

A boot's outer fabric is typically treated with a Durable Water Repellent (DWR) finish. This chemical coating causes water to bead up and roll off the surface, keeping the material from absorbing moisture. This is crucial for maintaining the "air gap" the membrane needs to breathe.

What Happens When DWR Fails

Over time, with abrasion and dirt, the DWR coating wears off. When this happens, the outer fabric becomes saturated with water, a phenomenon known as "wetting out."

This creates a layer of liquid water that completely covers the exterior of the breathable membrane. The escape route for your sweat vapor is now blocked, trapping all that warm, damp air inside your boot. Your foot feels clammy and wet, even though no external water has breached the membrane.

Comparing Common Outer Materials

Synthetic Fabrics (Nylon, Polyester)

These are the most common materials in modern hiking and tactical boots. They offer an excellent balance of durability and low weight.

Crucially, synthetic fabrics are highly air-permeable when dry. This allows for maximum airflow and helps sweat vapor escape quickly. However, their breathability is entirely dependent on a functioning DWR coating to prevent them from becoming waterlogged.

Full-Grain Leather

Full-grain leather is exceptionally durable and can be made highly water-resistant with proper treatment (waxes or oils).

However, leather is naturally less air-permeable than synthetic fabrics. While it does breathe to some extent, it relies more on its ability to absorb and slowly release moisture over time. All-leather boots often feel warmer and can take longer to dry out once saturated.

Hybrid Constructions (Leather and Fabric)

Many boots combine leather panels for durability in high-wear areas with synthetic fabric or mesh panels in other areas.

This design aims for the best of both worlds: the ruggedness of leather and the superior ventilation of synthetics. The mesh panels, in particular, dramatically increase airflow, making the boot feel cooler and dry faster.

Understanding the Trade-offs

The "Waterproof but Sweaty" Problem

This is the most common pitfall. A boot can be perfectly waterproof yet leave your feet soaked in sweat if the outer material wets out. Many users blame the GORE-TEX liner when the real culprit is a saturated outer fabric that needs its DWR treatment refreshed.

Material Choice vs. Intended Use

There is no single "best" material. A heavy, all-leather boot is a poor choice for a hot, dry desert mission where maximum ventilation is key. Likewise, a lightweight fabric boot with mesh panels would be ill-suited for rugged, abrasive mountain terrain.

The Misconception of "Drying Inward"

The idea that moisture stored between the layers flows back into the boot to dry when you take it off is fundamentally incorrect. The physics of diffusion and vapor pressure drive moisture from high-concentration areas (inside the boot) to low-concentration areas (outside). Trapped moisture will always seek the path of least resistance to the open air.

Making the Right Choice for Your Goal

The best material depends entirely on your environment and activity level.

- If your primary focus is maximum breathability in hot, dry conditions: Choose a boot with large synthetic mesh panels and minimal leather. Non-waterproof options will always be the most breathable.

- If your primary focus is all-around performance in varied, wet conditions: A hybrid boot with synthetic fabric and targeted leather reinforcements is ideal. Prioritize maintaining the DWR finish.

- If your primary focus is maximum durability and water resistance in harsh, abrasive environments: A full-grain leather boot is the most reliable choice, but accept that it will be less breathable than synthetic options.

Ultimately, the outer material is not just a protective shell; it is an active component of your boot's entire moisture management system.

Summary Table:

| Material Type | Breathability (When Dry) | Effect When Wet (Wetted Out) | Best Use Case |

|---|---|---|---|

| Synthetic (Nylon/Polyester) | High (Very air-permeable) | Becomes a vapor barrier, traps moisture | Hot, dry conditions; activities requiring maximum ventilation |

| Full-Grain Leather | Moderate (Less air-permeable) | Slower to dry, relies on absorption | Harsh, abrasive environments; maximum durability |

| Hybrid (Leather & Fabric) | Good (Balanced ventilation & durability) | Performance depends on panel saturation | Varied, wet conditions; all-around performance |

Need to source high-performance boots with the right outer material for your market?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We understand the critical role of material selection in breathability and performance. Our production capabilities encompass all types of shoes and boots, from durable full-grain leather work boots to highly breathable synthetic hiking models.

Let us help you select or develop the perfect boot for your target audience and climate. Contact our expert team today to discuss your manufacturing needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene