At its core, the midlayer of a safety boot is the unseen workhorse responsible for both comfort and stability. It achieves this by providing crucial shock absorption and housing the boot's shank, which together reduce foot fatigue and ensure the boot flexes correctly for stable movement on demanding surfaces.

The midlayer acts as the boot's suspension and chassis. It absorbs the punishing impacts of a long workday while providing the rigid-yet-flexible structure your foot needs to remain stable and supported.

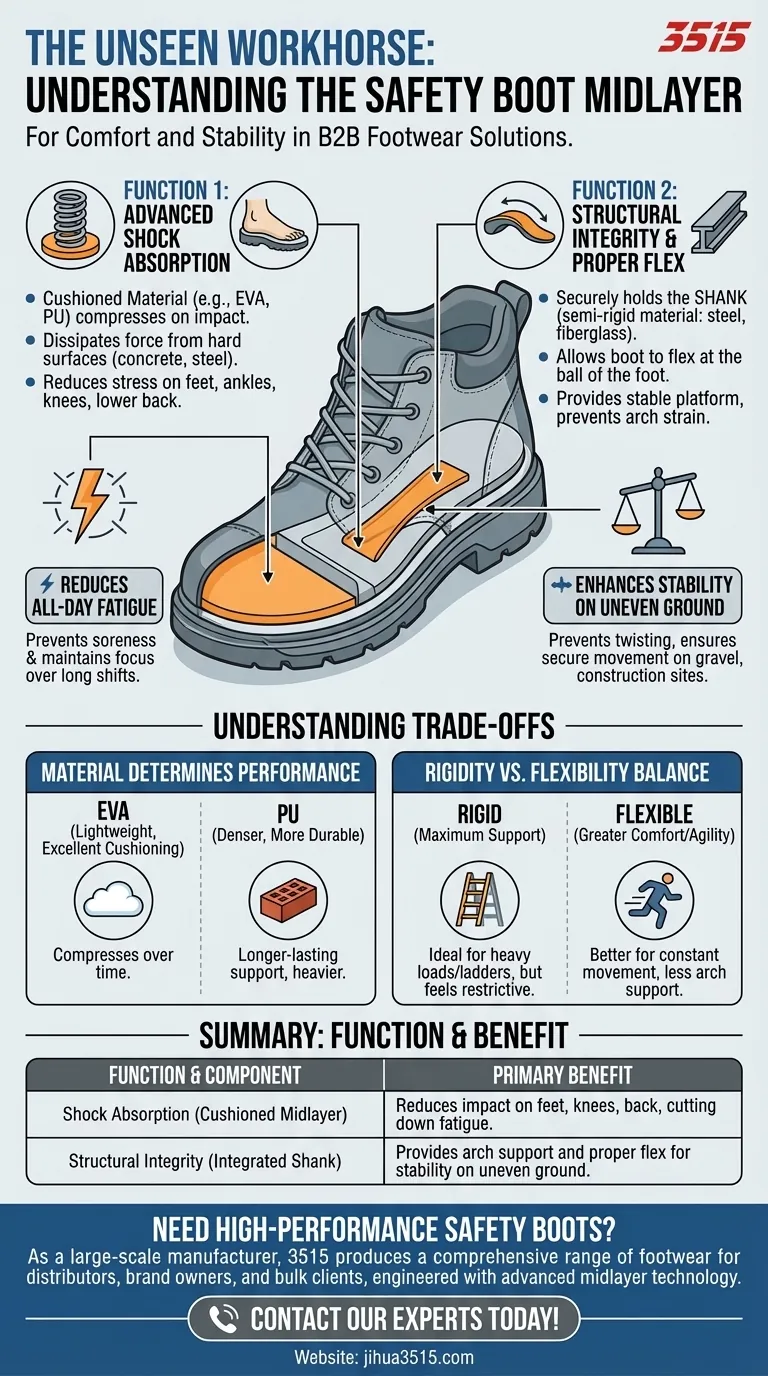

The Two Core Functions of the Midlayer

To truly understand a safety boot's performance, you must look beyond the steel toe and rugged exterior to the engineered layer under your foot. The midlayer dictates how the boot feels and responds with every step.

Function 1: Advanced Shock Absorption

The most immediate contribution to comfort is shock absorption. The midlayer is typically made of a cushioned material that compresses on impact.

This function is critical for dissipating the force generated from walking or standing, especially on hard, unforgiving surfaces like concrete or steel.

By absorbing this impact, the midlayer reduces the stress not only on your feet but also on your ankles, knees, and lower back, significantly cutting down on end-of-day fatigue.

Function 2: Structural Integrity and Proper Flex

The midlayer provides the boot's structural foundation by securely holding the shank. The shank is a semi-rigid piece of material (often steel, fiberglass, or plastic) that runs under the arch of your foot.

This integration of the shank is what allows the boot to flex correctly at the ball of your foot, rather than collapsing in the arch.

This controlled flex provides a stable platform for movement, prevents arch strain, and is essential for maintaining balance, particularly when climbing ladders or navigating uneven ground.

How the Midlayer Impacts Your Workday

The technical functions of the midlayer translate directly into tangible benefits that affect your safety and endurance on the job.

Reducing All-Day Foot Fatigue

The combination of shock absorption and proper arch support means your muscles don't have to work as hard to stabilize your feet and absorb impacts.

Over thousands of steps in a single shift, this energy-saving design is the primary factor in preventing the soreness and fatigue that can compromise focus and safety.

Enhancing Stability on Uneven Ground

On unpredictable surfaces like gravel, construction sites, or outdoor terrain, the midlayer and its integrated shank are your first line of defense against slips and ankle rolls.

The structure prevents the boot from twisting, ensuring your foot remains planted and secure, giving you the confidence to move safely and efficiently.

Understanding the Trade-offs

Not all midlayers are created equal. The materials and design involve a balancing act between different performance characteristics.

Material Determines Performance

The specific material used in the midlayer, often foams like EVA (ethylene vinyl acetate) or Polyurethane (PU), dictates its properties.

EVA is lightweight and offers excellent cushioning but can compress and lose its effectiveness over time. PU is denser and more durable, providing longer-lasting support, but is often heavier.

The Rigidity vs. Flexibility Balance

A boot with a very rigid midlayer and a strong shank provides maximum support and protection, which is ideal for carrying heavy loads or working on ladders.

However, this rigidity can feel restrictive for jobs that require constant walking or kneeling. A more flexible midlayer offers greater comfort and agility but provides less arch support and torsional stability.

Making the Right Choice for Your Goal

By understanding the midlayer, you can select a boot tailored to the specific demands of your job.

- If your primary focus is working on hard, flat surfaces: Prioritize a boot with a thick, well-cushioned midlayer to maximize shock absorption and fight fatigue.

- If your primary focus is navigating uneven terrain or climbing: Seek a boot with a robust midlayer and a strong shank for superior stability and arch support.

- If your primary focus is agility and constant movement: Consider a boot with a more flexible midlayer that allows for a natural range of motion without sacrificing essential support.

Ultimately, choosing the right safety boot means understanding its internal architecture to ensure it supports you effectively through every hour of your workday.

Summary Table:

| Function | Key Component | Primary Benefit |

|---|---|---|

| Shock Absorption | Cushioned Midlayer (EVA/PU) | Reduces impact on feet, knees, and back, cutting down fatigue. |

| Structural Integrity | Integrated Shank (Steel/Fiberglass) | Provides arch support and proper flex for stability on uneven ground. |

Need safety boots that won't let you down? As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with advanced midlayer technology for superior comfort and stability. Let us help you equip your workforce with footwear that supports them all day long. Contact our experts today to discuss your requirements!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments