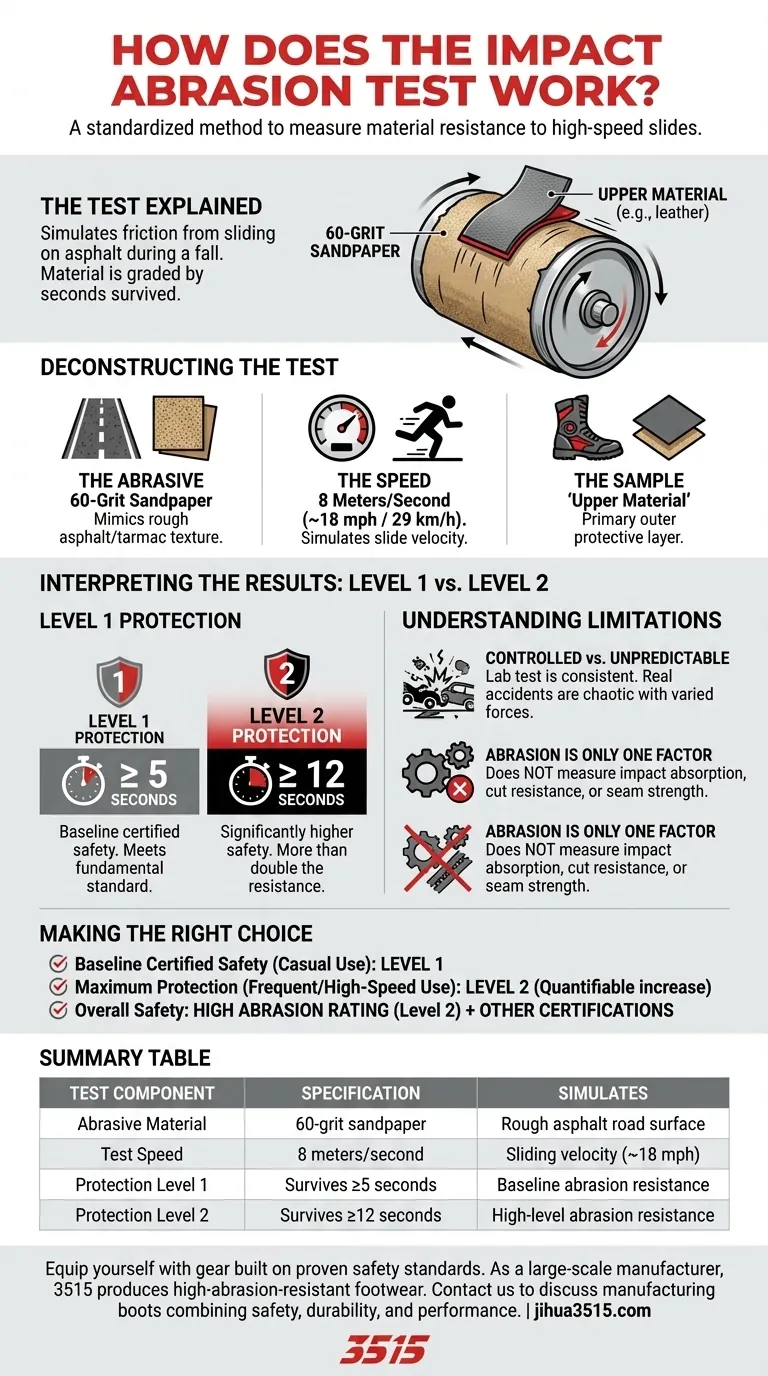

The impact abrasion test is a standardized method used to measure a material's resistance to being worn away during a high-speed slide. It works by pressing a sample of the material against a strip of 60-grit sandpaper moving at 8 meters per second, simulating the friction from sliding on asphalt during a fall. The material's performance is then graded based on how many seconds it survives before a hole is worn through it.

This test provides a critical, data-driven benchmark for the protective capability of materials used in gear like motorcycle boots. It moves beyond marketing claims to offer a measurable assessment of how well a material can protect you from road rash.

Deconstructing the Test: What Each Component Simulates

To understand the results, you must first understand the components of the test itself. Each element is designed to replicate a specific aspect of a real-world accident scenario, providing a controlled and repeatable environment for evaluation.

The Abrasive: 60-Grit Sandpaper

The choice of 60-grit sandpaper is not arbitrary. This specific level of coarseness is used to mimic the rough, abrasive texture of a typical asphalt or tarmac road surface.

The Speed: 8 Meters per Second

A speed of 8 m/s (approximately 18 mph or 29 km/h) is used to simulate the velocity of a slide. While initial crash speeds may be higher, this represents a significant and sustained sliding force where abrasion resistance is most critical.

The Sample: "Upper Material"

The test is performed on the "upper material," which is the primary outer layer of the product being tested, such as the leather or textile on a motorcycle boot. This is the first and most important line of defense against abrasion injuries.

Interpreting the Results: Level 1 vs. Level 2

The test's outcome is not just a pass or fail but is categorized into two distinct levels of performance. These levels provide a clear hierarchy of protection for the consumer.

Defining Level 1 Protection

To achieve a Level 1 rating, the material sample must withstand the abrasion test for a minimum of 5 seconds before a hole is formed. This is the baseline standard for certified protective performance.

Defining Level 2 Protection

A Level 2 rating is significantly more demanding. The material must survive for at least 12 seconds under the same conditions. This represents more than double the abrasion resistance of Level 1 and indicates a much higher level of safety.

Understanding the Limitations

While the impact abrasion test is an excellent tool, it's important to recognize what it does and does not measure. Objectivity requires understanding the context of any standardized test.

A Controlled vs. Unpredictable Environment

The test provides a consistent benchmark. However, a real-world accident is chaotic, involving unpredictable surfaces, tumbling motions, and multiple types of forces that a single lab test cannot fully replicate.

Abrasion is Only One Factor

This test specifically measures abrasion resistance. It does not measure other critical safety factors like impact absorption (crush resistance), cut resistance, or the strength of the seams and stitching, which are also vital for overall protection.

Making the Right Choice for Your Gear

Use these performance levels as a key data point when evaluating the safety of your equipment.

- If your primary focus is baseline certified safety for casual use: A Level 1 rating ensures the material has met a fundamental standard for abrasion protection.

- If your primary focus is maximum protection for frequent or high-speed use: A Level 2 rating provides a quantifiable and significant increase in the time the material can protect you during a slide.

- If your primary focus is overall safety: Look for a high abrasion rating (ideally Level 2) in conjunction with other certifications for impact protection and robust construction.

Ultimately, understanding this test empowers you to choose gear based on objective performance data rather than just appearance or brand.

Summary Table:

| Test Component | Specification | Simulates |

|---|---|---|

| Abrasive Material | 60-grit sandpaper | Rough asphalt road surface |

| Test Speed | 8 meters/second | Sliding velocity in a fall (~18 mph) |

| Protection Level 1 | Survives ≥5 seconds | Baseline abrasion resistance |

| Protection Level 2 | Survives ≥12 seconds | High-level abrasion resistance |

Equip yourself with gear built on proven safety standards. As a large-scale manufacturer, 3515 produces a comprehensive range of high-abrasion-resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure that every pair meets rigorous protective benchmarks. Contact us today to discuss manufacturing boots that combine safety, durability, and performance.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.