To be direct, the additional materials used in a welt and a multi-layered sole construction will always make a shoe heavier than one with a simpler, cemented sole. This added weight is not an incidental byproduct, but a direct consequence of building a shoe for maximum durability and repairability. The heft you feel is a tangible indicator of the shoe's robust architecture.

The crucial insight is that the increased weight from a welted sole is a deliberate trade-off. You are exchanging a lighter feel for a significant gain in longevity, water resistance, and the ability to rebuild the shoe, extending its useful life far beyond that of more lightweight alternatives.

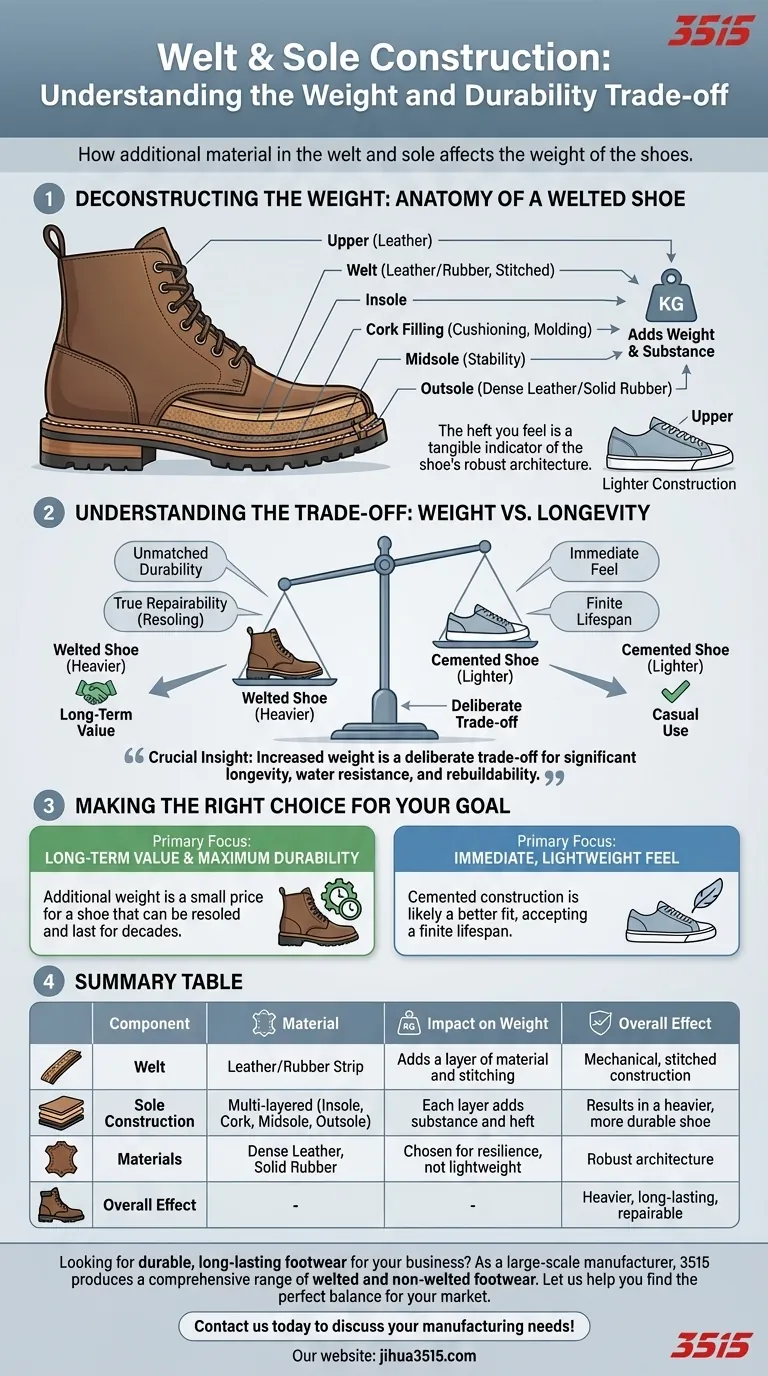

Deconstructing the Weight: Anatomy of a Welted Shoe

To understand why welted shoes are heavier, we must look at their core components. Unlike a simple sneaker where the upper is essentially glued to a single-piece sole, a welted shoe is a more complex, layered system.

The Function of the Welt

A welt is a strip of material, typically leather, that is stitched to the edge of the shoe's upper. This welt then has the outsole stitched to it.

This extra component creates a secure, mechanical bond between the upper and the sole. It acts as a robust intermediary, adding a layer of material and heavy-duty stitching that simply doesn't exist in lighter constructions.

The Multi-Layered Sole

Welted shoes rarely have a simple, single-piece sole. The structure is typically built in layers, much like the foundation of a house.

These layers often include an insole, a cork filling for cushioning and molding to the foot, a midsole for stability, and finally the outsole that contacts the ground. Each layer adds to the shoe's substance and, consequently, its weight.

The Impact of Material Density

The materials used are chosen for resilience, not for being lightweight. Welted footwear often features dense leathers and thick, solid rubber for the soles.

This contrasts sharply with the lightweight EVA foams and thin rubber found on athletic or casual shoes, which are designed for flexibility and minimal weight at the expense of long-term durability.

Understanding the Trade-off: Weight vs. Longevity

The decision to accept the additional weight of a welted shoe comes down to a clear cost-benefit analysis. The "cost" is the physical heft, while the "benefit" is a dramatic increase in the shoe's lifespan and performance.

The Primary Benefit: Unmatched Durability

The stitched construction of a welted shoe is inherently stronger and more reliable than a glued (cemented) bond. It is far less likely to delaminate or separate over time, especially under stress or in adverse weather conditions.

The Key Feature: True Repairability

Because the outsole is stitched to the welt and not directly to the upper, a skilled cobbler can remove the old sole and stitch on a new one without compromising the shoe's structure. This resoling capability is the primary reason welted shoes can last for decades, whereas a cemented shoe is often discarded once its original sole wears out.

The Drawback: The Initial Feel

There is no denying that the additional weight is noticeable, especially if you are accustomed to lighter footwear. Welted shoes also typically have a stiffer feel out of the box and may require a break-in period as the thick leather and cork footbed mold to your foot.

Making the Right Choice for Your Goal

Ultimately, the right choice depends on what you value most in a pair of shoes.

- If your primary focus is long-term value and maximum durability: The additional weight is a small price to pay for a shoe that can be resoled and will last for years, if not decades.

- If your primary focus is an immediate, lightweight feel for casual or short-term use: A non-welted, cemented construction is likely a better fit for your needs, accepting that it will have a finite lifespan.

The weight of a welted shoe is a clear indicator of its construction philosophy and its potential for a long and serviceable life.

Summary Table:

| Component | Material | Impact on Weight |

|---|---|---|

| Welt | Leather/Rubber Strip | Adds a layer of material and stitching |

| Sole Construction | Multi-layered (Insole, Cork, Midsole, Outsole) | Each layer adds substance and heft |

| Materials | Dense Leather, Solid Rubber | Chosen for resilience, not lightweight |

| Overall Effect | Mechanical, stitched construction | Results in a heavier, more durable shoe |

Looking for durable, long-lasting footwear for your business? As a large-scale manufacturer, 3515 produces a comprehensive range of welted and non-welted footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots built to last. Let us help you find the perfect balance of durability and weight for your target market.

Contact us today to discuss your manufacturing needs!

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What are the benefits of breathable mesh in shoe design? Enhance Comfort and Performance

- What are the characteristics of canvas as a shoe material? A Guide to Lightweight, Breathable Footwear

- Does more ground contact area mean better support? Unlock the Secrets of Stable Footwear

- What are the features of cross training shoes? Master Versatile Performance for Your Workouts

- How do athletic shoes with non-slip features differ from regular ones? Discover the Grip Advantage