In short, cowboy boot stitching is both a critical structural component and a defining decorative element. While the elaborate patterns on the boot's shaft are largely for aesthetic appeal and brand identity, other stitches are essential for holding the entire boot together, ensuring it can withstand the rigors of its work environment.

The core purpose of cowboy boot design is rugged utility. Stitching reinforces this principle by providing structural integrity while simultaneously offering a canvas for the boot's iconic, decorative artistry.

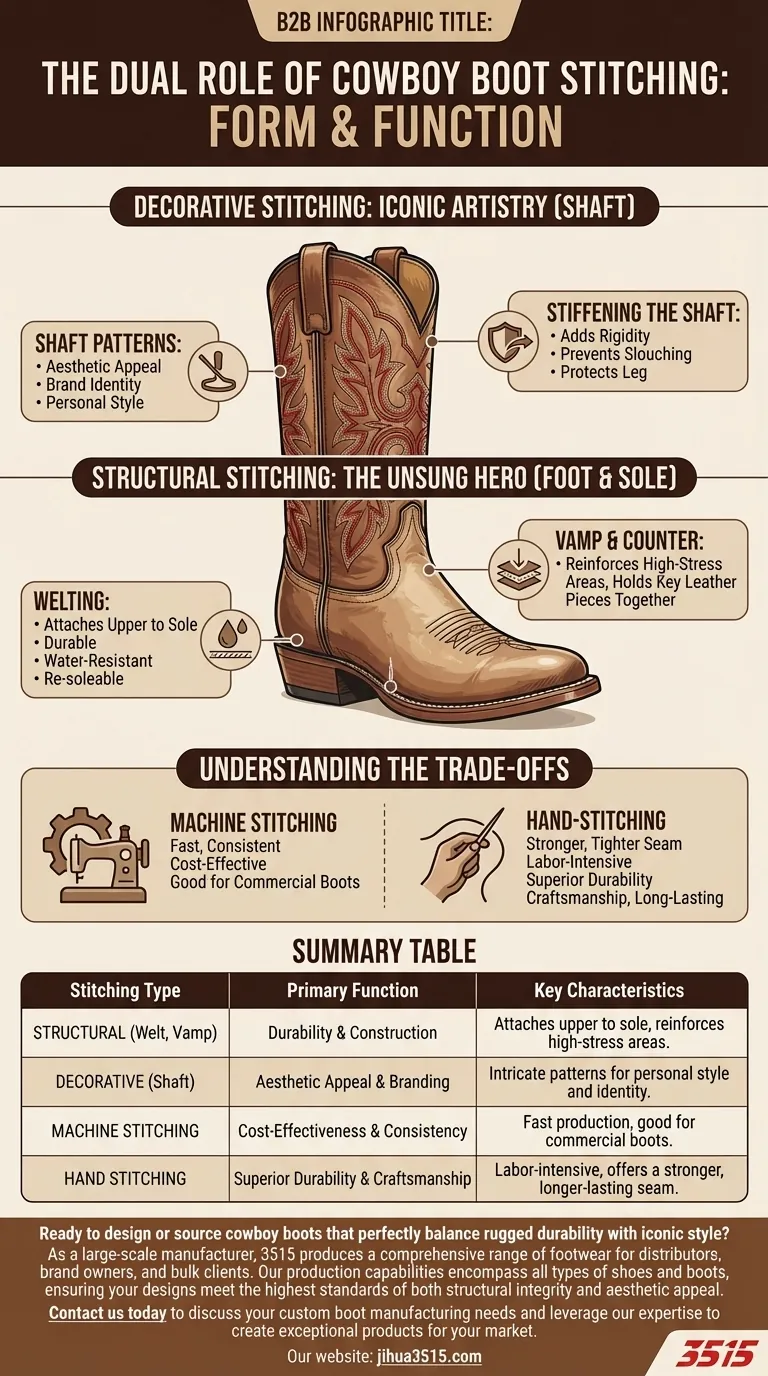

The Dual Role of Stitching: Form and Function

Cowboy boots are a masterclass in functional design, and stitching is central to their construction. We can separate its role into two primary categories: structural and decorative.

Structural Stitching: The Unsung Hero

The most important stitches on a cowboy boot are the ones you might not notice first. They are purely functional, designed for maximum durability.

Welting: This is a crucial stitch that attaches the upper part of the boot to the sole. A goodyear welt, for example, is a time-tested method that creates a highly durable, water-resistant, and re-soleable boot.

Vamp and Counter: Stitches around the foot (vamp) and heel (counter) are also structural. They hold these key leather pieces together, reinforcing the areas that experience the most stress and wear.

Decorative Stitching: The Iconic Artistry

This is the stitching most people associate with cowboy boots—the intricate, often colorful patterns that adorn the tall shaft.

Shaft Patterns: These elaborate designs were traditionally used as a form of branding for different bootmakers. Today, they serve primarily as a decorative element, allowing for personal expression and style.

Stiffening the Shaft: While largely aesthetic, dense stitching on the shaft does add some rigidity. This helps the boot shaft stand tall and prevents it from slouching, which also contributes to the boot's protective qualities.

Understanding the Trade-offs in Stitching

Not all stitching is created equal. The quality and method used have a significant impact on the boot's longevity and cost.

Machine vs. Handmade Stitching

Machine Stitching: Most commercially produced boots use machine stitching. It's fast, consistent, and cost-effective, but may not offer the same level of long-term durability as high-quality hand-stitching.

Hand-Stitching: Found on custom and high-end boots, hand-stitching allows for a stronger, tighter seam. This traditional method is labor-intensive and expensive but results in a superior product that can last for decades with proper care.

The Myth of "Purely" Decorative

Even the most ornate stitching on the shaft serves a secondary function. It reinforces the leather and helps the shaft maintain its shape, offering better protection for the rider's leg against brush, fences, and other hazards.

Making the Right Choice for Your Goal

Understanding the role of stitching helps you choose the right boot for your needs.

- If your primary focus is durability and work: Pay close attention to the welt construction and the quality of the structural stitching around the foot and sole.

- If your primary focus is style and personal expression: You can focus more on the aesthetic appeal of the decorative shaft stitching, choosing patterns and colors that match your taste.

Ultimately, the best cowboy boots are those where both functional and decorative stitching are executed with exceptional skill.

Summary Table:

| Stitching Type | Primary Function | Key Characteristics |

|---|---|---|

| Structural (Welt, Vamp) | Durability & Construction | Attaches upper to sole, reinforces high-stress areas. |

| Decorative (Shaft) | Aesthetic Appeal & Branding | Intricate patterns for personal style and identity. |

| Machine Stitching | Cost-Effectiveness & Consistency | Fast production, good for commercial boots. |

| Hand Stitching | Superior Durability & Craftsmanship | Labor-intensive, offers a stronger, longer-lasting seam. |

Ready to design or source cowboy boots that perfectly balance rugged durability with iconic style?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring your designs meet the highest standards of both structural integrity and aesthetic appeal.

Contact us today to discuss your custom boot manufacturing needs and leverage our expertise to create exceptional products for your market.

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What role do pneumatic fixtures play in supporting automated footwear assembly? Precision Stability for Robotics

- What are the advantages of using high-durability protective equipment? Ensure Safety and Operational Resilience

- Why is it necessary to configure professional footwear for virtual pedestrian testing? Ensure Biomechanical Accuracy

- How often should camouflage clothing be washed? Preserve Performance & Longevity

- What precautions should be taken when ironing Cordura fabric? Avoid Melting & Damage with Low Heat

- What role do industrial-grade nine-axis IMUs play in motion recognition for footwear? Enhance Gait Tracking Precision

- What is the role of industrial motor-driven treadmills in running gait research? Precision Tools for Gait Analysis

- What role does statistical analysis software play in evaluating the impact of augmented reality (AR) technology on footwear purchase decisions? Quantify Its Impact.