To be clear, the Occupational Safety and Health Administration (OSHA) enforces safety shoe compliance primarily through unannounced workplace inspections. During these inspections, compliance officers assess job site hazards and verify that employers are ensuring their workers wear personal protective equipment (PPE), including footwear that meets recognized industry standards for the risks present.

The core principle is not about specific "OSHA-approved" shoes, but about the employer's responsibility. OSHA mandates that employers must conduct a hazard assessment and ensure employees wear footwear that meets the appropriate ASTM International standard for protection against those specific hazards.

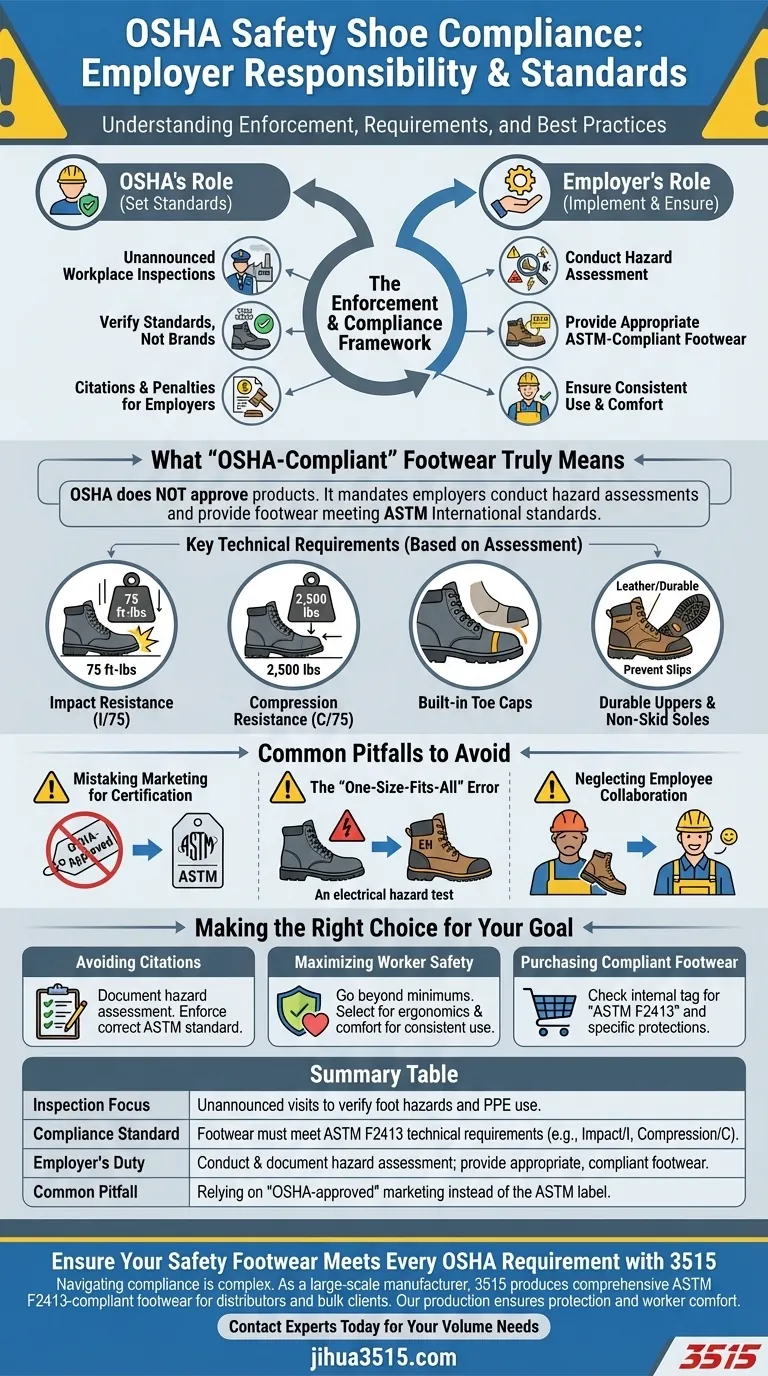

The Enforcement and Compliance Framework

OSHA's role is to set the standards for safety, while the employer's role is to implement them. The enforcement process is designed to verify that this implementation is happening correctly.

The Role of Workplace Inspections

OSHA compliance officers conduct inspections to identify and address workplace dangers. If foot hazards exist, such as the risk of falling objects or punctures, the officer will check for the use of protective footwear.

Verifying the Standard, Not the Brand

Compliance officers are not looking for a specific brand of shoe. They are verifying that the footwear meets the technical requirements necessary to protect against the identified risks.

This means checking that the shoe is appropriate for the job and adheres to consensus standards like ASTM F2413, which specifies performance requirements for protective footwear.

Citations and Penalties

If an inspector finds that employees are exposed to foot hazards without adequate protective footwear, the employer—not the employee—can receive a citation and face financial penalties.

What "OSHA-Compliant" Footwear Truly Means

The term "OSHA-compliant" can be misleading. OSHA does not approve, certify, or endorse any specific product. Instead, it defines the conditions under which protective footwear must be used and references standards that the footwear must meet.

The Employer's Responsibility

The foundation of compliance is the employer's hazard assessment. The employer must survey the workplace to identify potential foot injuries from impact, compression, punctures, or electrical hazards.

Key Technical Requirements

Based on that assessment, the employer must ensure the provided or required footwear has the necessary protective features. Key requirements often include:

- Impact Resistance (I/75): Protects the toe area from an impact of 75 foot-pounds.

- Compression Resistance (C/75): Protects the toe area from a compressive load of 2,500 pounds.

- Built-in Toe Caps: A mandatory feature for impact and compression resistance.

- Durable Uppers: Materials like leather are frequently required for overall durability and protection.

- Non-Skid Soles: To prevent slips and falls.

Common Pitfalls to Avoid

True compliance goes beyond simply buying a pair of steel-toed boots. Avoiding common misunderstandings is critical for maintaining a safe and citation-free workplace.

Mistaking Marketing for Certification

Do not rely on marketing claims of "OSHA-approved." Look for the specific ASTM standard (e.g., ASTM F2413) printed on a label inside the shoe's tongue or collar. This is the true mark of compliance.

The "One-Size-Fits-All" Error

A standard safety-toe boot may not protect against every hazard. If electrical risks are present, for example, footwear with an Electrical Hazard (EH) rating is necessary. The shoe must match the specific danger.

Neglecting Employee Collaboration

Footwear that is uncomfortable or fits poorly will not be worn consistently. Involving employees in the selection process improves compliance and overall safety culture.

Making the Right Choice for Your Goal

Your approach to safety footwear should be driven by a clear understanding of your responsibilities and goals.

- If your primary focus is avoiding citations: Perform and document a thorough foot hazard assessment for every job role, and then enforce the use of footwear meeting the correct ASTM standard for those identified hazards.

- If your primary focus is maximizing worker safety: Go beyond the minimum requirements by selecting footwear that also addresses ergonomics and comfort, which encourages consistent and proper use by your team.

- If your primary focus is purchasing compliant footwear: Always check the shoe's internal tag for explicit confirmation that it meets "ASTM F2413" standards for impact and compression, along with any other special protections needed.

Ultimately, a proactive safety culture built on proper hazard assessment is the definitive path to ensuring both compliance and worker protection.

Summary Table:

| Key Aspect | What OSHA Checks For |

|---|---|

| Inspection Focus | Unannounced workplace visits to identify foot hazards and verify PPE use. |

| Compliance Standard | Footwear must meet the technical requirements of ASTM F2413 for identified risks (e.g., Impact/I, Compression/C). |

| Employer's Duty | Conduct and document a hazard assessment; provide appropriate, standard-compliant footwear. |

| Common Pitfall | Relying on "OSHA-approved" marketing instead of the ASTM label inside the shoe. |

Ensure Your Safety Footwear Meets Every OSHA Requirement

Navigating OSHA compliance for safety shoes is complex, but sourcing the right footwear doesn't have to be. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed to protect against specific hazards while ensuring worker comfort for consistent use.

Let us help you build a safer, compliant workplace. Contact our experts today to discuss your specific needs and volume requirements.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- What are the conditions faced by employees in meatpacking and poultry slaughter plants? Navigating Pervasive Slip Hazards

- What materials are used in the construction of these boots? A Guide to Velour Leather, Textile & PU Soles

- What does a green triangle symbol on safety footwear mean? Your Guide to Maximum Puncture & Impact Protection

- Why is expert help recommended when selecting safety shoes? Ensure Perfect Fit & Hazard Protection

- What do the markings on ASTM-compliant safety shoes indicate? Decode the Safety Labels for Maximum Protection