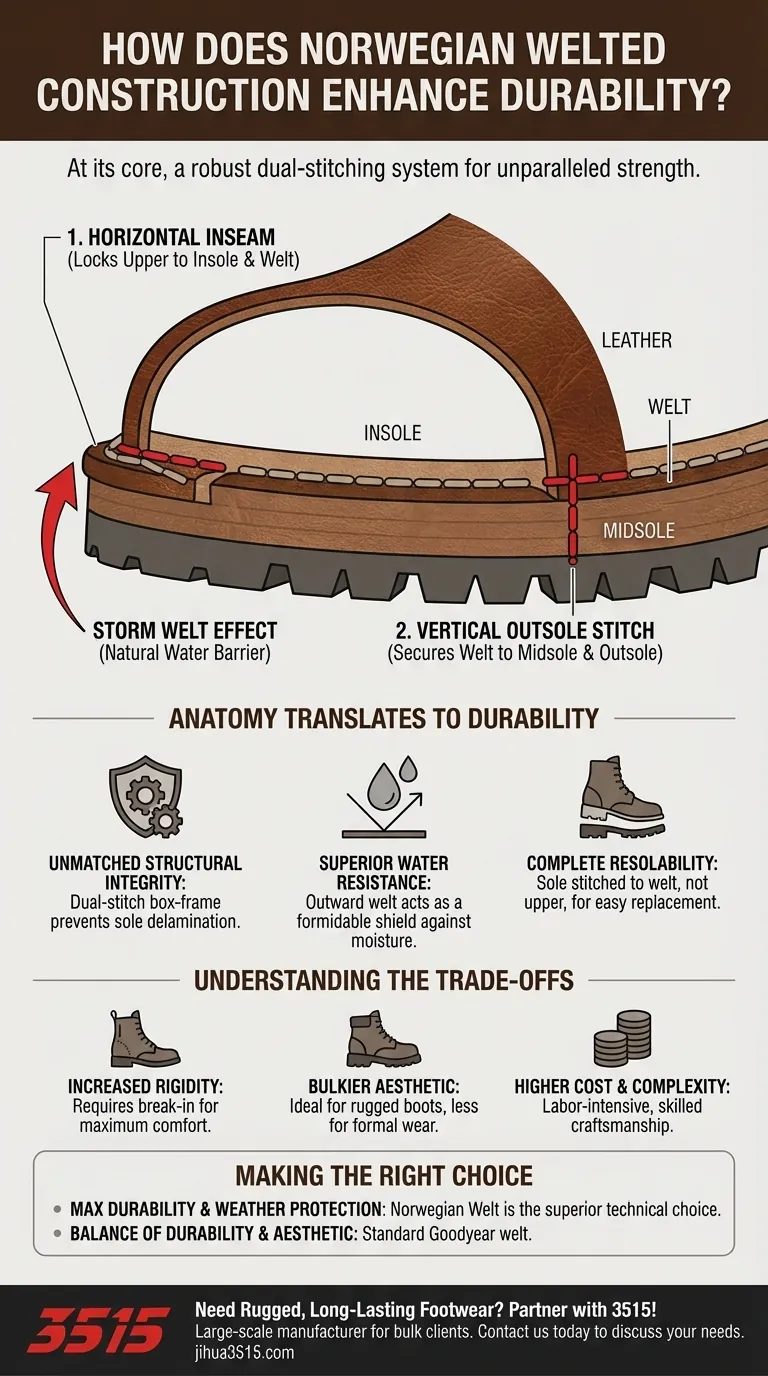

At its core, Norwegian Welted Construction enhances durability through a robust dual-stitching system. This method first stitches the shoe's upper and a leather strip (the welt) horizontally to the insole, creating an exceptionally secure foundation. A second, visible stitch then runs vertically through that same welt and into the outsole, effectively locking the entire shoe together with two independent seams for unparalleled strength.

Choosing truly durable footwear requires looking beyond the leather to the method of assembly. Norwegian Welted Construction provides superior longevity by creating two layers of structural stitching, resulting in a shoe that is not only tougher but also significantly more water-resistant than most other methods.

The Anatomy of a Norwegian Welt

To understand the durability, you must first understand the mechanics. This method is an evolution of the trusted Goodyear welt, engineered for even greater resilience.

A Foundation of Two Seams

Unlike simpler constructions that rely on a single stitch or glue, the Norwegian Welt uses two separate and powerful stitches. This creates redundancy and distributes stress across a wider, more secure area.

The First Stitch: Locking the Upper

The first stitch, often called the inseam, is the hidden workhorse. It runs horizontally, passing from the outside of the shoe through the upper, the welt, and a special ridge on the insole. This critical step securely anchors the upper part of the shoe to its foundation.

The Second Stitch: Securing the Sole

The second stitch is the one you can see running along the perimeter of the sole. This stitch passes vertically through the overhanging welt and directly into the midsole and outsole. This creates the final, rock-solid bond that holds the entire platform together.

The Result: An Integrated Barrier

Because the upper is turned outward before being stitched down, the construction forms a natural, protective lip around the base of the shoe. This "storm welt" effect creates a physical barrier that makes it very difficult for water to penetrate the seam.

How This Anatomy Translates to Durability

The specific design of the Norwegian Welt directly creates tangible benefits in strength, weather resistance, and lifespan.

Unmatched Structural Integrity

The two-stitch system—one horizontal, one vertical—creates a box-like frame at the shoe's most critical joint. This makes the shoe incredibly resistant to the twisting and pulling forces of rigorous use, preventing sole delamination.

Superior Water Resistance

The outward-facing welt acts as a formidable shield against moisture. For hiking, work, or navigating wet city streets, this construction provides a level of weather protection that most other methods, including a standard Goodyear welt, cannot match.

Complete Resolability

Just like a Goodyear welt, the outsole is stitched to the welt, not directly to the upper. This means a skilled cobbler can remove an old, worn-out sole and stitch on a new one without compromising the shoe's core structure, dramatically extending its usable life.

Understanding the Trade-offs

No construction method is perfect for every situation. The strengths of the Norwegian Welt come with specific characteristics you should be aware of.

Increased Rigidity

The same robust, dual-stitch construction that provides immense durability also results in a stiffer shoe out of the box. Norwegian welted footwear typically requires a more significant break-in period to achieve maximum comfort.

A Bulkier Aesthetic

The visible stitching and the way the upper flares out at the sole create a distinct, substantial profile. This makes it an ideal choice for boots and rugged footwear but less suitable for sleek, formal dress shoes.

Higher Cost and Complexity

This is a labor-intensive technique that demands a high degree of skill. The time and craftsmanship required to execute the two separate stitches are naturally reflected in a higher price point.

Making the Right Choice for Your Goal

Ultimately, the best construction method depends entirely on your intended use.

- If your primary focus is maximum durability and weather protection for outdoor or heavy use: The Norwegian Welt is the superior technical choice for its robust build and inherent water resistance.

- If your primary focus is a balance of durability and a streamlined aesthetic for business or city wear: A standard Goodyear welt offers excellent longevity and resolability with a less bulky profile.

- If your primary focus is immediate comfort and flexibility for light, casual wear: A Blake stitch or cemented construction may be more suitable, though it comes at the expense of long-term durability and water resistance.

Understanding how a shoe is built is the first step toward investing in footwear that will truly serve its purpose.

Summary Table:

| Key Feature | Durability Benefit |

|---|---|

| Dual-Stitch System | Creates redundancy and superior structural integrity, preventing sole delamination. |

| Outward-Facing Welt | Acts as a natural barrier, offering exceptional water resistance for harsh conditions. |

| Stitched Construction | Allows for easy resoling by a cobbler, dramatically extending the shoe's lifespan. |

| Rigid Build | Provides a robust foundation, ideal for heavy-duty and outdoor use after a break-in period. |

Need Rugged, Long-Lasting Footwear? Partner with 3515!

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including advanced constructions like the Norwegian Welt for maximum durability and weather resistance.

Let us help you build a product line that stands the test of time. Contact our team today to discuss your manufacturing needs!

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Why is it important to invest in a good pair of work boots? Maximize Safety & Save Money Long-Term

- How long do work boots typically last? Maximize Lifespan & Safety

- Why is rotating two pairs of work boots recommended? Double Boot Life & Boost Foot Health

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety