In short, National Fire Protection Association (NFPA) standards no longer permit the use of leather in firefighter turnout gear. This change was driven by significant concerns over the material's inability to be properly decontaminated after exposure to hazardous substances, directly impacting firefighter health and safety.

The prohibition of leather in turnout gear marks a critical evolution in firefighter safety. It reflects a shift in priority from traditional durability to the paramount importance of mitigating long-term health risks, specifically exposure to carcinogens that cannot be washed out of porous materials.

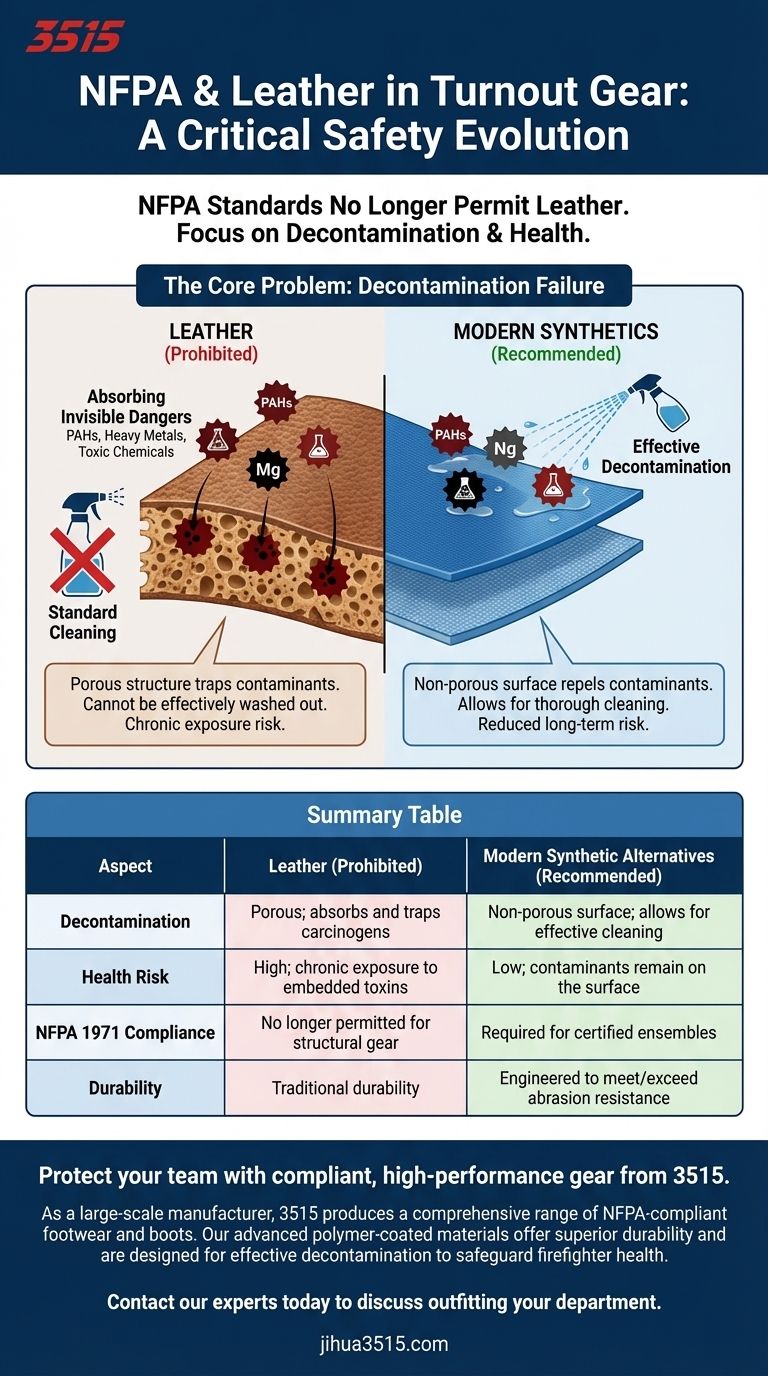

The Core Problem: Decontamination Failure

The fundamental reason for the NFPA's decision lies in the physical properties of leather. Unlike modern synthetic materials, leather presents a persistent contamination risk that cannot be easily solved.

The Porous Nature of Leather

Leather, particularly when it's abraded, scuffed, or in the form of suede, acts like a sponge. Its porous structure readily absorbs liquids and particulates from the fireground.

These substances become deeply embedded within the material's fibers, making them nearly impossible to remove completely.

Absorbing Invisible Dangers

During a fire, gear is coated in a cocktail of hazardous materials, including carcinogens like polycyclic aromatic hydrocarbons (PAHs), heavy metals, and other toxic chemicals.

When these substances soak into leather, they create a reservoir of contamination. The gear may look clean, but it can continue to off-gas or transfer these toxins to the firefighter's skin long after the incident is over.

Why Standard Cleaning Isn't Enough

Advanced washing procedures are effective on non-porous surfaces. However, they cannot penetrate and extract the deeply embedded contaminants within leather.

This means that even after following proper decontamination protocols, leather components can remain a source of chronic exposure, undermining the entire cleaning process.

The Shift to Safer Alternatives

The move away from leather is part of a broader industry trend toward materials engineered specifically for the fire service environment, prioritizing both performance and health.

The Rise of Polymer-Coated Fabrics

Modern turnout gear now uses synthetic materials, such as polymer-coated aramid fabrics, for reinforcement in high-wear areas like knees and cuffs.

These materials are engineered to be non-porous. Their smooth, resilient surface prevents contaminants from being absorbed in the first place.

The Benefit of a Cleanable Surface

The key advantage of these synthetic alternatives is their decontaminability. Hazardous substances remain on the surface, allowing them to be washed away effectively during the cleaning process.

This ensures that the gear can be returned to a safe state for the next use, drastically reducing the risk of long-term toxic exposure.

Making the Right Choice for Your Department

Understanding this standard is crucial for ensuring compliance and protecting your personnel. The focus must be on materials that support a complete decontamination cycle.

- If your primary focus is compliance: Immediately audit all turnout gear to ensure no leather components are present on any NFPA-certified structural firefighting ensembles.

- If your primary focus is firefighter health: Prioritize materials specifically designed for easy and thorough decontamination, recognizing that this is a critical link in cancer prevention efforts.

- If your primary focus is long-term durability: Select gear that uses modern, high-tenacity polymer-coated materials, which are engineered to meet or exceed the abrasion resistance of leather without the associated health risks.

Ultimately, this change in standards reflects the fire service's growing commitment to protecting firefighters not just from immediate threats, but from the cumulative dangers they face throughout their careers.

Summary Table:

| Aspect | Leather (Prohibited) | Modern Synthetic Alternatives (Recommended) |

|---|---|---|

| Decontamination | Porous; absorbs and traps carcinogens | Non-porous surface; allows for effective cleaning |

| Health Risk | High; chronic exposure to embedded toxins | Low; contaminants remain on the surface |

| NFPA 1971 Compliance | No longer permitted for structural gear | Required for certified ensembles |

| Durability | Traditional durability | Engineered to meet/exceed abrasion resistance |

Protect your team with compliant, high-performance gear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of NFPA-compliant footwear and boots for distributors, brand owners, and bulk clients. Our advanced polymer-coated materials offer superior durability and, most importantly, are designed for effective decontamination to safeguard firefighter health.

Contact our experts today to discuss outfitting your department with safer, modern turnout gear.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- Why are professional safety shoes required during heavy-duty girder erection? Essential Protection for Infrastructure

- What safety standards should oilfield work boots meet? Ensure OSHA & ASTM F2413 Compliance

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What is the core protective function of steel-toe safety shoes in preventing lower limb injuries caused by chainsaws?

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?