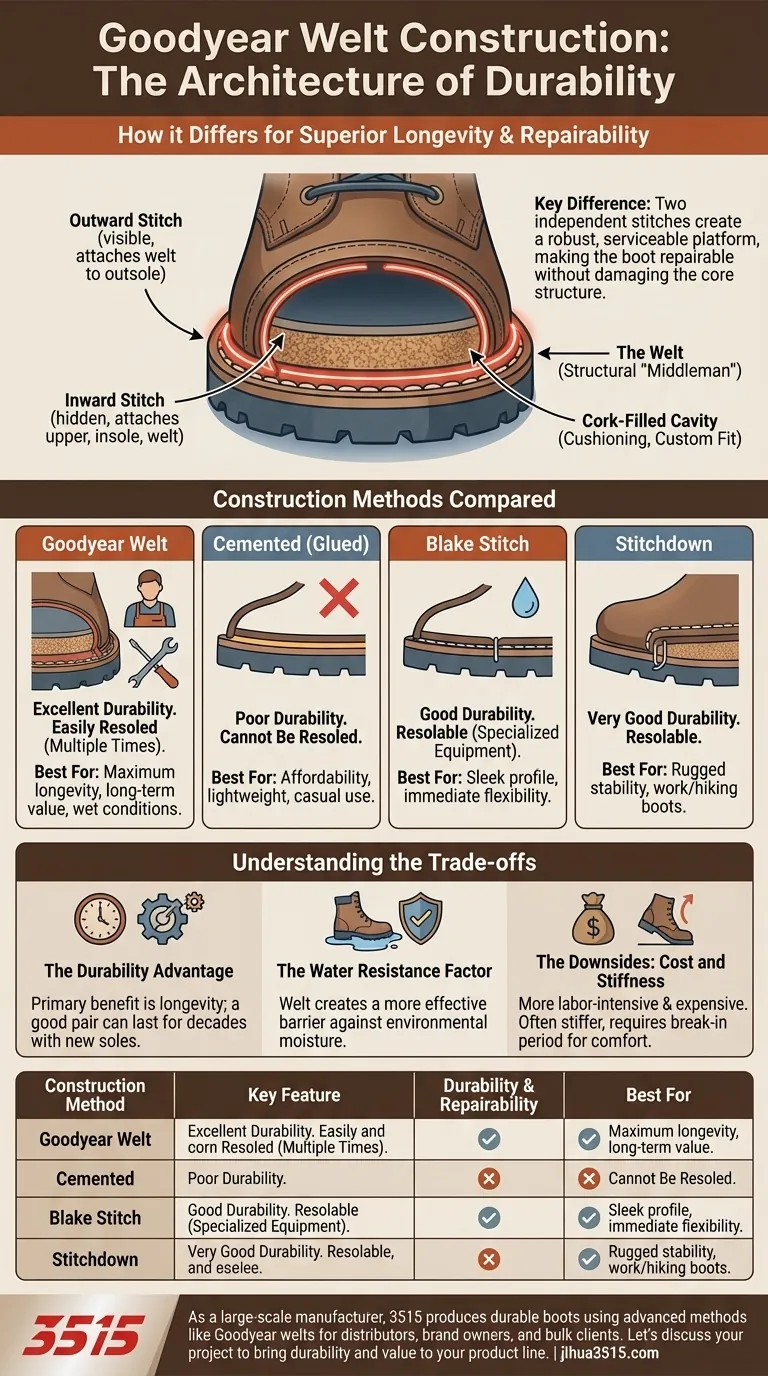

At its core, Goodyear welt construction differs from other methods by using a separate strip of material—the welt—as a stitched intermediary between the boot's upper and its outsole. This creates two independent stitches, which makes the boot exceptionally durable, water-resistant, and, most importantly, easy to resole multiple times without damaging the core structure. Other common methods either glue the components together or stitch them directly, limiting repairability and longevity.

The crucial difference isn't just the presence of a stitch, but the architecture of that stitch. A Goodyear welt creates a robust, serviceable platform for the boot's sole, fundamentally changing its lifecycle from disposable to repairable.

The Mechanics of a Goodyear Welt

To understand why a Goodyear welt is so highly regarded, you must first understand its components. It is a machine-based process that creates a near-indestructible bond between the parts of a boot.

The Role of the Welt

The welt is a strip of leather or rubber that runs along the perimeter of the outsole. It acts as a structural "middleman."

Instead of attaching the upper directly to the outsole, the welt is first stitched to the upper and the insole.

The Two-Level Stitch

This process creates two separate and independent stitches. The first, an inward stitch, attaches the upper, the insole, and the welt together.

The second, an outward stitch (often visible on the boot), attaches the welt to the outsole. Because the outsole is only stitched to the welt, a cobbler can easily remove the old sole and stitch on a new one without affecting the upper.

The Cork-Filled Cavity

The construction method creates a cavity between the insole and the midsole. This space is typically filled with cork, which provides cushioning, insulation, and breathability.

Over time, the cork filling molds to the shape of your foot, creating a custom-like fit. A steel shank is also often embedded in this layer for arch support and to maintain the boot's shape.

How Other Constructions Compare

The value of the Goodyear welt becomes clearest when compared directly to the other primary methods of boot construction. Each has its own place, but they serve different purposes.

Cemented Construction

This is the most common and least expensive method. The boot's sole is simply glued to the upper using a strong adhesive, often with heat and pressure.

While this creates a lightweight and flexible boot, the bond will eventually fail, and the boots generally cannot be resoled.

Blake Stitch Construction

A Blake stitch involves a single stitch that runs directly from the inside of the boot, through the insole and upper, and into the outsole.

This creates a more flexible and sleeker profile than a Goodyear welt. However, it compromises water resistance (water can wick up the thread) and makes resoling more difficult, requiring specialized machinery.

Stitchdown Construction

Often used for rugged work or hiking boots, this method involves flanging the leather upper outward and stitching it directly to the midsole and outsole.

Stitchdown construction is very durable and stable, but it typically offers less water resistance at the seam compared to a well-executed welt.

Storm Welt (An Enhanced Goodyear)

A Storm welt is a variation of the Goodyear welt that uses a wider welt. This extra width is bent upward against the upper, creating a tighter seal.

This design significantly increases moisture protection, making it a superior choice for wet and harsh environments.

Understanding the Trade-offs

No single construction method is perfect for every application. The Goodyear welt's strengths come with specific considerations.

The Durability Advantage

The primary benefit is longevity. Because the upper is not compromised during resoling, a well-cared-for pair of Goodyear-welted boots can last for decades, receiving new soles as needed.

This makes them a better long-term investment than boots that must be discarded once the sole wears out.

The Water Resistance Factor

The welt creates a more effective barrier between the boot's upper and the ground. While not fully waterproof without other features, it provides significantly more protection from environmental moisture than cemented or Blake-stitched footwear.

The Downsides: Cost and Stiffness

The complexity of the Goodyear welt process makes it more labor-intensive and expensive.

These boots also tend to be stiffer out of the box and require a break-in period for the leather and cork to conform to your foot. This initial stiffness is a trade-off for their eventual comfort and structural integrity.

Choosing the Right Construction for Your Needs

Your decision should be guided by your priorities for the footwear.

- If your primary focus is maximum durability and repairability: Goodyear welt is the undisputed standard for long-term value and a "buy it for life" mentality.

- If your primary focus is a sleek profile and immediate flexibility: A Blake stitch offers a durable, stitched construction without the bulk or break-in period of a welt.

- If your primary focus is affordability and casual use: Cemented construction provides a lightweight, comfortable option for less demanding scenarios where longevity is not the main concern.

- If your primary focus is maximum water resistance in harsh conditions: A Storm welt provides an extra layer of protection over the standard Goodyear welt, making it ideal for wet climates.

Understanding these construction methods empowers you to invest not just in a pair of boots, but in the right tool for your specific purpose.

Summary Table:

| Construction Method | Key Feature | Durability & Repairability | Best For |

|---|---|---|---|

| Goodyear Welt | Separate welt strip; two-level stitch | Excellent; easily resoled multiple times | Maximum durability, long-term value, wet conditions |

| Cemented (Glued) | Sole glued to the upper | Poor; generally cannot be resoled | Affordability, lightweight, casual use |

| Blake Stitch | Single stitch from the inside | Good; resolable with specialized equipment | Sleek profile, immediate flexibility |

| Stitchdown | Upper flanged outward and stitched | Very good; resolable | Rugged stability, work/hiking boots |

Ready to Invest in Superior Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable boots using advanced construction methods like Goodyear welts for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you receive high-quality, long-lasting footwear built to meet your specific market demands.

Let's discuss your project: Contact our team today to explore how we can bring durability and value to your product line.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What is the function of impact-resistant toe caps in safety footwear? Protect Your Feet During Heavy Lifting

- What protective features do professional Safety Shoes provide in shipyard environments? Maximize Worker Safety

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions

- Why is the anti-smash feature essential in palm oil processing areas? Ensure Worker Safety from Heavy Machinery Risks

- What are the primary protective functions of industrial-grade safety shoes during heavy machinery maintenance such as ship engine overhauls? Essential Protection for Extreme Environments.