In the world of quality footwear, the construction method is the foundation of a shoe's character, dictating its durability, repairability, and long-term value. A Goodyear welt uses a strip of leather (the welt) to stitch the upper and the sole together, creating a robust and easily resoleable shoe. In contrast, cemented construction involves gluing the sole directly to the upper, resulting in a lighter, more flexible, and less expensive shoe that is difficult to repair.

The choice between Goodyear welt and cemented construction is a fundamental trade-off. Goodyear welt is an investment in long-term durability and the ability to rebuild the shoe over decades, while cemented construction prioritizes initial affordability, lightweight comfort, and stylistic flexibility.

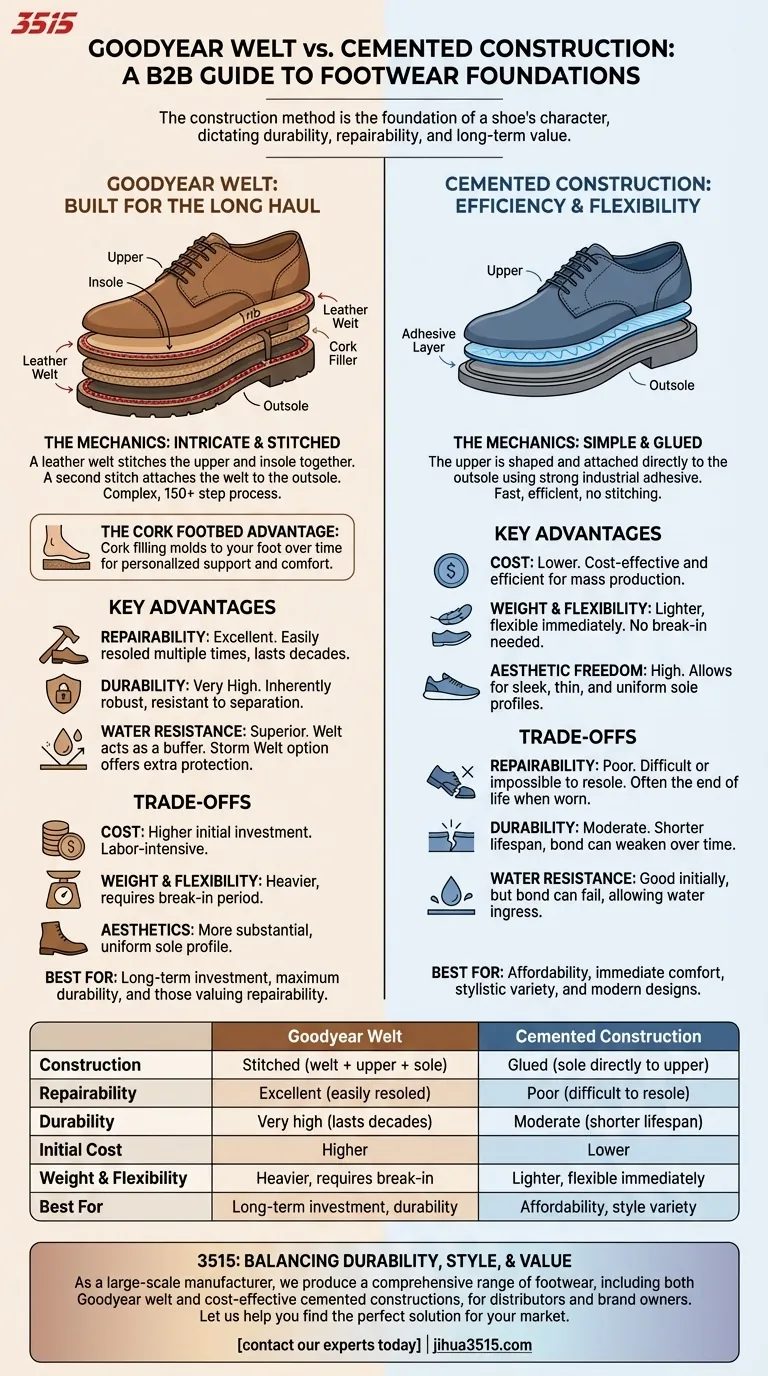

The Mechanics of Construction: Stitching vs. Gluing

To understand the difference in performance, you must first understand the difference in process. One is an intricate, multi-stage operation, while the other is a model of industrial efficiency.

How Goodyear Welt Works

The Goodyear welt process is a complex craft involving over 150 distinct steps.

First, the upper is attached to a "rib" on the insole. A leather strip, the welt, is then stitched through the upper and the insole rib.

This creates a durable, unified component separate from the outsole. This initial stitch also forms a cavity under the insole, which is filled with a layer of granulated cork.

Finally, a second, heavy-duty stitch—visible on the top edge of the sole—attaches the welt to the outsole, completing the shoe.

The Cork Footbed Advantage

That cork filling is a key feature of Goodyear welted shoes. Over time, the pressure and heat from your foot cause the cork to compress and mold to its unique shape.

This creates a personalized, supportive footbed that increases in comfort the more you wear the shoe.

An Expert Variation: The Storm Welt

A storm welt is a variation of the Goodyear welt that uses a wider strip of leather. This extra width is bent upwards against the upper, creating a more pronounced barrier against moisture. It offers superior water resistance for demanding environments.

How Cemented Construction Works

Cemented construction is a much simpler and faster process. The shoe's upper is shaped and then attached directly to the outsole using a strong, industrial-grade adhesive.

There is no welt and no stitching holding the sole in place. This method is highly efficient and allows for a wide variety of materials and sole shapes.

Key Differences in Ownership Experience

The construction method directly impacts how a shoe wears, lasts, and feels over its lifetime.

Repairability and Longevity

This is the most significant difference. Goodyear welted shoes are designed to be resoled. A cobbler can simply cut the stitch holding the welt to the outsole, attach a new sole, and stitch it back on without disturbing the upper. This can be done multiple times, allowing a quality pair of shoes to last for decades.

Cemented shoes are extremely difficult, and often impossible, to resole. The process of prying off a glued sole can damage the upper, and re-gluing a new one rarely creates a reliable bond. For most cemented shoes, a worn-out sole means the end of the shoe's life.

Water Resistance

The Goodyear welt creates a more effective seal between the upper and the sole. The welt acts as a buffer, making it much harder for water to penetrate the shoe from below, especially with a storm welt.

Glued soles can provide an initial seal, but this bond can weaken over time, creating gaps where water can enter.

Durability

The stitched construction of a Goodyear welt is inherently more durable and robust than a glued bond. It is less likely to fail or separate under high stress or with prolonged wear.

Understanding the Trade-offs

Neither method is universally superior; they are simply engineered for different priorities. Choosing the right one requires acknowledging the trade-offs.

Cost

Goodyear welting is a labor-intensive and expensive process requiring skilled operators and specialized machinery. This results in a significantly higher initial purchase price.

Cemented construction is fast, efficient, and less expensive, making it the standard for most mass-market footwear.

Weight and Flexibility

The multiple layers, welt, and cork filling make Goodyear welted shoes heavier and more rigid out of the box. They require a "break-in" period as the leather and cork footbed conform to your foot.

Cemented shoes are significantly lighter and more flexible from the very first wear, offering immediate comfort without a break-in period.

Aesthetic Freedom

The nature of Goodyear welting typically results in a more substantial and uniform sole profile.

Cemented construction allows for greater design flexibility. Soles can be made thinner and shaped into more delicate or aggressive profiles, such as chisel toes or sleek, low-profile designs.

Making the Right Choice for Your Goal

Your ideal construction method depends entirely on what you value most in a shoe.

- If your primary focus is lifetime value and durability: Choose a Goodyear welted shoe for its exceptional longevity and the ability to be resoled multiple times.

- If your primary focus is affordability and immediate comfort: Opt for cemented construction, which offers a lower entry price and a flexible feel right out of the box.

- If your primary focus is stylistic variety and modern design: Consider cemented shoes, as this method allows for a wider range of sleek and lightweight sole profiles.

Understanding these foundational differences empowers you to look beyond simple aesthetics and invest in footwear that truly aligns with your needs and expectations.

Summary Table:

| Feature | Goodyear Welt | Cemented Construction |

|---|---|---|

| Construction | Stitched (welt + upper + sole) | Glued (sole directly to upper) |

| Repairability | Excellent (easily resoled) | Poor (difficult to resole) |

| Durability | Very high (lasts decades) | Moderate (shorter lifespan) |

| Initial Cost | Higher | Lower |

| Weight & Flexibility | Heavier, requires break-in | Lighter, flexible immediately |

| Best For | Long-term investment, durability | Affordability, style variety |

Need footwear that balances durability, style, and value? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including both durable Goodyear welt and cost-effective cemented constructions. Let us help you find the perfect solution for your market — contact our experts today to discuss your needs!

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort

- Which type of sole is better for hard surfaces? Rubber Soles for Superior Comfort & Durability

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality

- What are the advantages of rubber-soled shoes? Unlock Superior Grip & All-Day Comfort

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained