At its core, cushioning in work boots degrades primarily through a process called compression set, where materials like foam lose their ability to absorb shock after repeated impact from daily use. This breakdown is why regular checks are critical; what was once a protective shock absorber can become a direct transmitter of force to your feet, joints, and back, compromising both safety and comfort.

The most significant mistake is judging a work boot's health by its external appearance. The internal cushioning is a hidden, critical safety component that wears out silently, turning your primary protective gear into a potential liability without obvious visual cues.

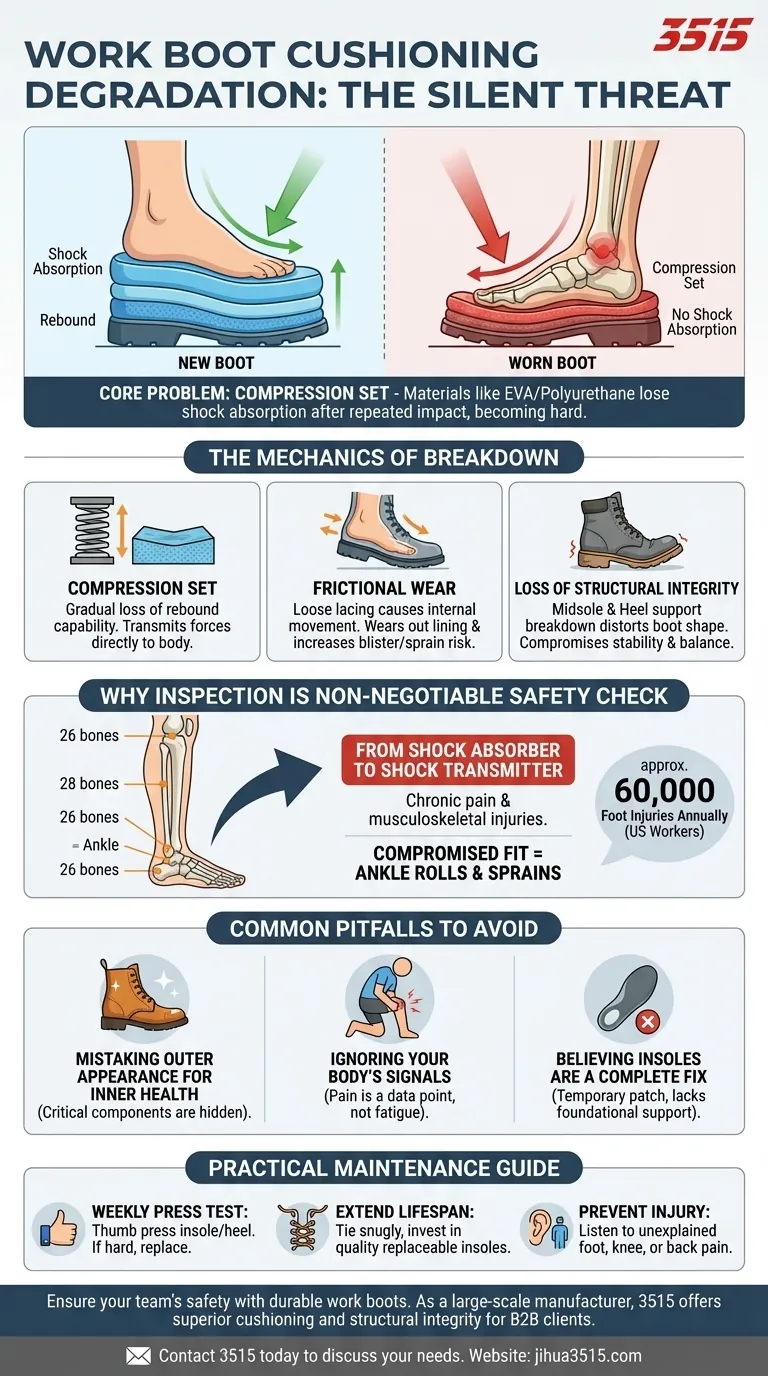

The Mechanics of Cushioning Breakdown

Understanding how the supportive elements of your boots fail is the first step toward preventing the negative consequences. It’s a gradual process driven by consistent, everyday forces.

The Impact of Compression Set

The primary function of cushioning, often made of EVA foam or polyurethane, is shock absorption.

With every step, this material compresses to soak up impact. Over time and thousands of compressions, it loses its ability to rebound to its original shape. This is compression set.

When this happens, the material becomes packed down and hard, offering little to no shock absorption and transferring impact forces directly to your body.

Frictional Wear and Tear

How you tie your boots has a direct impact on their lifespan.

If boots are not laced snugly, your feet and ankles can slide around inside. This constant movement creates friction that prematurely wears out the boot's inner lining and the top layer of the inner sole.

This friction not only degrades the materials but also contributes to an improper fit, which increases the risk of blisters and sprains.

Loss of Structural Integrity

Cushioning isn't just the removable insole; it's an entire system.

The boot's midsole (the layer between the insole and the outsole) and the heel structure provide foundational support.

These components also break down from daily use, leading to a distorted boot shape and uneven wear. This loss of structure can compromise the stability of your entire foot, affecting your gait and overall balance.

Why Regular Inspection is a Non-Negotiable Safety Check

A worn-out boot is more than just uncomfortable; it's a safety hazard. The human foot contains a complex structure of 26 bones, and protecting it is essential for preventing serious, work-halting injuries.

From Shock Absorber to Shock Transmitter

Effective cushioning diffuses the force of each step. Worn cushioning does the opposite.

It becomes a hard, unyielding surface that transmits shock directly into your heel, ankle, knee, and even lower back. This can lead to chronic pain and long-term musculoskeletal injuries.

The Danger of a Compromised Fit

A boot that fit perfectly when new can become dangerously loose as its internal padding and support degrade.

This poor fit allows your foot to move excessively, significantly increasing the risk of ankle rolls and sprains. It negates many of the boot's core protective features, turning a tool for safety into a source of instability.

The Hidden Costs of Neglect

Ignoring boot degradation has consequences. The approximately 60,000 foot injuries reported annually among American workers are a stark reminder of the risks.

Neglecting your primary point of contact with the ground can lead to injuries ranging from punctures and sprains to chronic conditions that impact your ability to work effectively.

Common Pitfalls to Avoid

Trusting assumptions over objective checks is a common mistake that can lead to preventable injury and discomfort.

Mistaking Outer Appearance for Inner Health

A boot's leather or synthetic upper can look nearly new while the internal midsole and insole are completely compressed and useless.

Never judge a boot's protective capability by its exterior. The critical components are hidden from view.

Ignoring Your Body's Signals

Pain is a data point. If your feet, knees, or back begin to ache after a workday, it is often one of the first and most reliable signs that your boot's cushioning system is failing.

Do not dismiss this discomfort as simple fatigue. It is your body telling you that your equipment is no longer providing adequate support.

Believing Insoles Are a Complete Fix

Replacing a worn-out inner sole can certainly extend the life and comfort of a boot, but it's not a cure-all.

If the boot's core midsole and heel structure are also degraded, a new insole is merely a temporary patch on a failing system. The lack of foundational stability will remain a problem.

A Practical Guide to Boot Maintenance

Your approach should be guided by your primary goal, whether it's maximizing safety, budget, or long-term health.

- If your primary focus is daily safety: Perform a weekly "press test" by pushing your thumb firmly into the insole and heel area; if it feels hard and doesn't compress, it's time for a replacement.

- If your primary focus is extending boot lifespan: Always tie your boots snugly to prevent internal movement and consider investing in high-quality, replaceable inner soles from the start.

- If your primary focus is preventing long-term injury: Listen to your body—unexplained foot, knee, or back pain is the most important indicator that your boots' support system is failing.

Proactive inspection transforms your work boots from a passive requirement into an active tool for your long-term health and safety.

Summary Table:

| Key Factor | How It Degrades Cushioning | Resulting Risk |

|---|---|---|

| Compression Set | Foam loses ability to rebound after repeated impacts. | Shock transmitted to joints, causing chronic pain. |

| Frictional Wear | Foot movement inside a loose boot wears down inner lining. | Blisters, sprains, and premature boot failure. |

| Loss of Structure | Midsole and heel support break down, distorting boot shape. | Compromised stability, poor balance, and gait issues. |

Don't let hidden boot wear compromise your team's safety and productivity. As a large-scale manufacturer, 3515 produces a comprehensive range of durable work boots and footwear designed to withstand daily demands. Our expertise ensures superior cushioning and structural integrity for distributors, brand owners, and bulk clients.

Contact 3515 today to discuss your footwear needs and discover how our production capabilities can deliver the reliable protection your customers deserve.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management