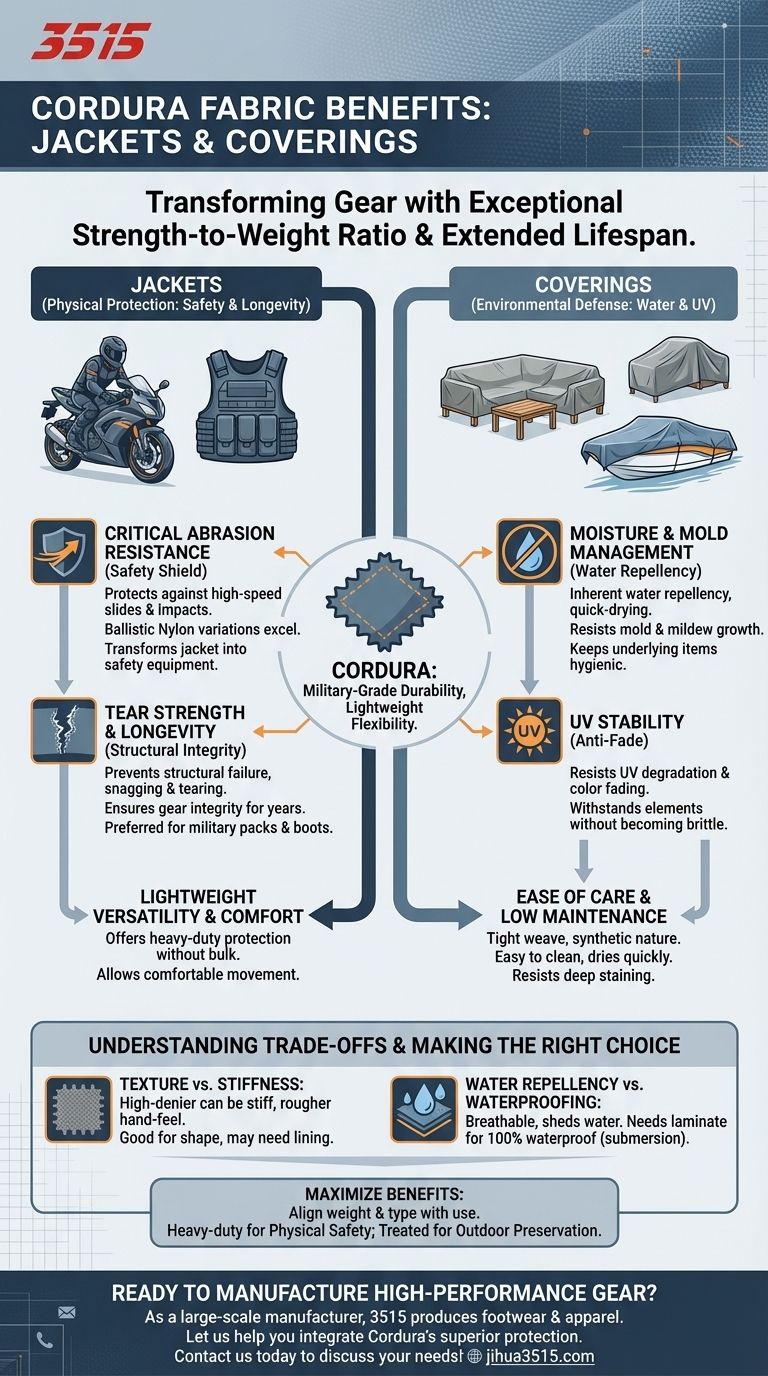

Cordura fabric transforms jackets and coverings by providing an exceptional strength-to-weight ratio that significantly extends the lifespan of the product. For jackets—specifically motorcycle and tactical gear—its primary benefit is critical abrasion resistance, acting as a protective shield against physical trauma. For coverings, such as outdoor furniture or marine equipment, its value lies in environmental defense, offering robust resistance against water, mildew, and UV fading.

Cordura is not just a "strong fabric"; it is a performance textile that balances military-grade durability with lightweight flexibility. It solves the problem of rapid wear-and-tear in high-stress environments without adding the bulk associated with traditional heavy canvas.

The Mechanics of Physical Protection

Abrasion Resistance for Safety

For applications like motorcycle jackets and tactical vests, the primary threat is friction. Cordura, particularly in its ballistic nylon variations, excels at resisting abrasion during slides or impacts.

This capability protects the wearer's skin from injury in high-speed scenarios. It transforms a standard jacket into a piece of safety equipment.

Tear Strength and Longevity

Beyond immediate safety, Cordura prevents the structural failure of the garment. It is highly resistant to tearing and snagging, which is common in rugged outdoor environments.

This durability ensures that gear maintains its integrity over years of use. It makes the material a preferred choice for military backpacks and boots where failure is not an option.

Weatherproofing and Outdoor Performance

Moisture and Mold Management

When used for coverings on outdoor furniture or watercraft, moisture retention is the enemy. Cordura features inherent water repellency and quick-drying properties.

Crucially, the fabric is engineered to resist mold and mildew growth. This protects the underlying items from rot and keeps the covering itself hygienic and structurally sound in damp conditions.

UV Stability

Outdoor coverings are constantly exposed to harsh sunlight, which degrades most fabrics. Cordura is formulated to resist UV fading and degradation.

This ensures that patio furniture covers or boat tarps retain their color and strength over time. The material withstands the elements without becoming brittle or bleached.

Comfort and Maintenance Profile

Lightweight Versatility

Despite its "military-grade" toughness, Cordura is surprisingly lightweight. It offers the protection of heavy leather or canvas without the associated weight penalty.

This allows for comfortable movement in jackets and easy handling when removing large covers. It strikes a necessary balance between heavy-duty performance and user comfort.

Ease of Care

Maintenance for Cordura products is straightforward. The fabric's tight weave and synthetic nature make it easy to clean.

Because it dries quickly and resists deep staining, it requires less frequent and less intensive washing than natural fibers. This low-maintenance aspect appeals to users who need gear that is "grab-and-go."

Understanding the Trade-offs

Texture and Stiffness

While versatile, high-denier Cordura (the measure of fiber thickness) can be stiff. The same properties that provide armor-like protection can result in a rougher hand-feel compared to natural fibers like cotton or wool.

In clothing, this may require a lining for comfort against the skin. For coverings, the stiffness is generally an asset, helping the item hold its shape.

Water Repellency vs. Waterproofing

It is important to distinguish between water resistance and waterproofing. While Cordura sheds water and dries fast, the weave itself is breathable.

For total submersion or extreme downpours, Cordura requires an additional back-coating or laminate to be 100% waterproof. Without this, it is best viewed as a highly water-resistant, breathable shell.

Making the Right Choice for Your Goal

To maximize the benefits of Cordura, align the specific fabric weight and type with your intended use case.

- If your primary focus is Physical Safety (Motorcycling/Tactical): Look for heavy-duty or "ballistic" Cordura weaves to maximize abrasion resistance and slide protection.

- If your primary focus is Outdoor Preservation (Furniture/Marine): Prioritize Cordura with treated water repellency and UV resistance to prevent mold and sun damage.

Ultimately, Cordura is the definitive choice when the application demands a material that must endure abuse without failing.

Summary Table:

| Benefit | Application | Key Feature |

|---|---|---|

| Abrasion & Tear Resistance | Motorcycle/Tactical Jackets | Protects against high-impact slides and wear |

| Water & UV Resistance | Outdoor/Marine Coverings | Prevents mold, mildew, and sun damage |

| Lightweight & Easy Care | All Products | Balances durability with comfort and low maintenance |

Ready to manufacture high-performance jackets or coverings with Cordura fabric?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear and apparel for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes, boots, and technical garments designed for durability and performance. Let us help you integrate Cordura's superior protection into your product line.

Contact us today to discuss your manufacturing needs!

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the advantages of using 2D video evaluation protocols in protective footwear testing? Boost R&D Efficiency

- How do professional orthopedic footwear manage quality of life for diabetic patients? Essential Protective Solutions

- What are the advantages of online survey tools for large-scale footwear market research? Speed Up Your Strategy Cycle

- What tips are provided for choosing winter-specific cycling shoes? A Guide to Staying Warm and Dry

- How do integrated vibratory motors in smart insoles optimize dynamic balance control? Mastering Stochastic Resonance

- What should be considered when selecting pull-on boots? Ensure a Perfect Fit and Superior Performance

- How do quick-release buckles and D-rings impact passive exoskeletons? Enhancing Rehabilitation Efficiency

- What are the common types of synthetic and fake leathers? A Guide to PU, PVC & Vegan Materials