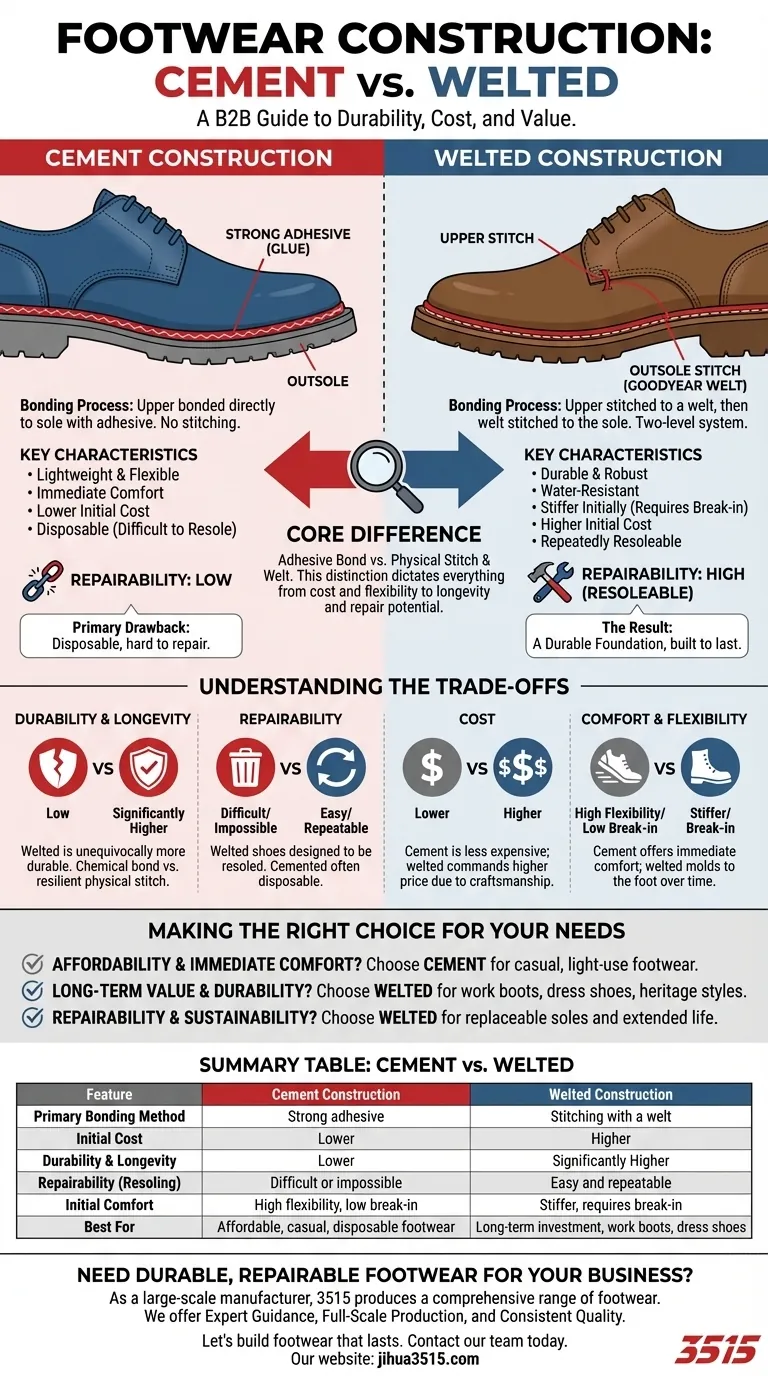

At its core, the difference is simple: cement construction uses a powerful adhesive to bond a shoe's upper directly to its sole, while welted construction uses a physical stitch and an intermediary strip of material. This fundamental distinction dictates everything about the footwear, from its initial cost and flexibility to its long-term durability and potential for repair.

Your choice between these two methods is a decision between short-term affordability and long-term value. Cemented shoes are built for accessibility and immediate comfort, while welted shoes are engineered as a durable, repairable investment.

The Anatomy of Cement Construction

Cement construction is the most common method for mass-market footwear, prized for its speed and efficiency. The process is straightforward and relies on modern adhesives.

The Bonding Process

The shoe's upper is shaped and then attached directly to the outsole using a strong, molten adhesive or cement. There is no stitching that connects the sole to the upper.

Key Characteristics

This direct glue-down method results in footwear that is often lightweight, flexible, and comfortable right out of the box. The lack of extra layers and stitching creates a sleek profile and reduces manufacturing costs significantly.

The Inherent Limitation

The primary drawback is repairability. When the adhesive bond fails or the sole wears out, it is extremely difficult—often impossible—to replace the sole without damaging the upper. This typically makes cemented shoes disposable.

Deconstructing Welted Construction

Welted construction is a hallmark of high-quality, traditional shoemaking. It involves more materials and skilled labor, creating a much more robust and serviceable product.

The Role of the Welt

A welt is a strip of leather, rubber, or plastic that runs along the perimeter of the outsole. This component acts as a crucial intermediary, connecting the upper to the sole without compromising the integrity of either.

The Stitching Method

The upper is stitched to the welt, and then the welt is separately stitched to the outsole. This two-level stitching process, known as a Goodyear welt, is the most durable method. It creates a highly secure, water-resistant, and endlessly repairable bond.

The Result: A Durable Foundation

Because the outsole is stitched to the welt rather than the upper, a cobbler can easily remove the old sole and stitch on a new one. This process, known as resoling, can be done multiple times, dramatically extending the life of the footwear.

Understanding the Trade-offs

The choice between cement and welted construction is a clear exercise in evaluating priorities. Each method offers distinct advantages and disadvantages.

Durability and Longevity

Welted construction is unequivocally more durable. The physical lock of the stitch is far more resilient to stress, moisture, and torsion than a chemical bond. A welted boot or shoe is built to last for years, often decades, with proper care.

Repairability

This is the most significant point of divergence. Welted shoes are designed to be resoled, making them a sustainable, long-term investment. Cemented shoes are generally considered disposable once the sole is compromised.

Cost

Cement construction is far less expensive due to lower material costs and faster, less labor-intensive manufacturing. This makes it the go-to method for affordable, everyday footwear. Welted shoes command a higher initial price due to the skilled craftsmanship required.

Comfort and Flexibility

Cemented shoes often win on initial comfort. They require little to no break-in period because the construction is inherently more flexible. Welted shoes are stiffer at first and require a break-in period as the leather and cork footbed mold to the wearer's foot.

Making the Right Choice for Your Needs

Selecting the right construction method depends entirely on your intended use, budget, and expectations for the footwear's lifespan.

- If your primary focus is affordability and out-of-the-box comfort: Cement construction is the logical choice for casual sneakers and light-use footwear.

- If your primary focus is long-term value and durability: Welted construction is a clear investment for work boots, high-quality dress shoes, and heritage footwear.

- If your primary focus is repairability and sustainability: Welted construction is the only practical option, allowing you to replace the sole and extend the shoe's life indefinitely.

Understanding this fundamental difference empowers you to invest in footwear that aligns perfectly with your expectations for cost, comfort, and lifespan.

Summary Table:

| Feature | Cement Construction | Welted Construction |

|---|---|---|

| Primary Bonding Method | Strong adhesive | Stitching with a welt |

| Initial Cost | Lower | Higher |

| Durability & Longevity | Lower | Significantly Higher |

| Repairability (Resoling) | Difficult or impossible | Easy and repeatable |

| Initial Comfort | High flexibility, low break-in | Stiffer, requires break-in |

| Best For | Affordable, casual, disposable footwear | Long-term investment, work boots, dress shoes |

Need Durable, Repairable Footwear for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Whether your market demands the affordability of cement construction or the unparalleled longevity of welted construction, we have the expertise and production capabilities to deliver.

We offer:

- Expert Guidance: Help you select the perfect construction method for your target audience and price point.

- Full-Scale Production: Capabilities encompassing all types of shoes and boots, from casual to heritage styles.

- Consistent Quality: Ensure your brand is associated with reliable and well-constructed footwear.

Let's build footwear that lasts. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health