For security guard safety boots, Goodyear welt construction offers superior long-term durability, repairability, and moisture resistance, making it the better choice for demanding roles. Cement construction provides a more affordable, lightweight, and flexible boot that is often more comfortable out of the box, but it cannot be easily repaired and is less resilient to heavy wear.

The decision between Goodyear welt and cement construction is a strategic choice between long-term investment and upfront cost. Goodyear welt is engineered for a lifetime of use and repair, while cement construction is designed for immediate comfort and affordability.

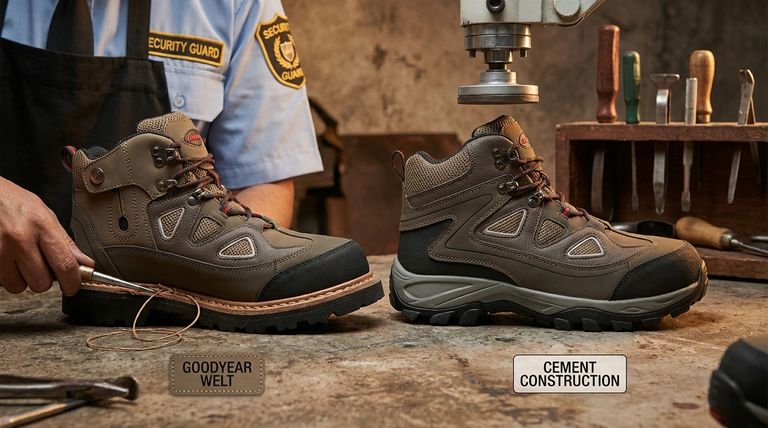

Deconstructing the Methods: Stitch vs. Glue

To understand the practical differences, you must first understand the fundamental engineering behind each method. One relies on a mechanical bond (stitching), while the other relies on a chemical bond (adhesive).

Cement Construction: The Adhesive Bond

In cement construction, the boot's upper is attached directly to the outsole using a strong, flexible adhesive. The process is fast and efficient.

This method results in a lighter and more flexible boot from the very first wear, as there are no rigid stitches to break in.

Goodyear Welt: The Stitched Foundation

Goodyear welt construction is a more complex, centuries-old technique. A leather strip called a welt is first stitched to the boot's upper. A separate stitch then attaches this welt to the outsole.

This double-stitch method creates an incredibly strong and secure bond between all parts of the boot. It also creates a small cavity that is often filled with cork, which molds to the wearer's foot over time.

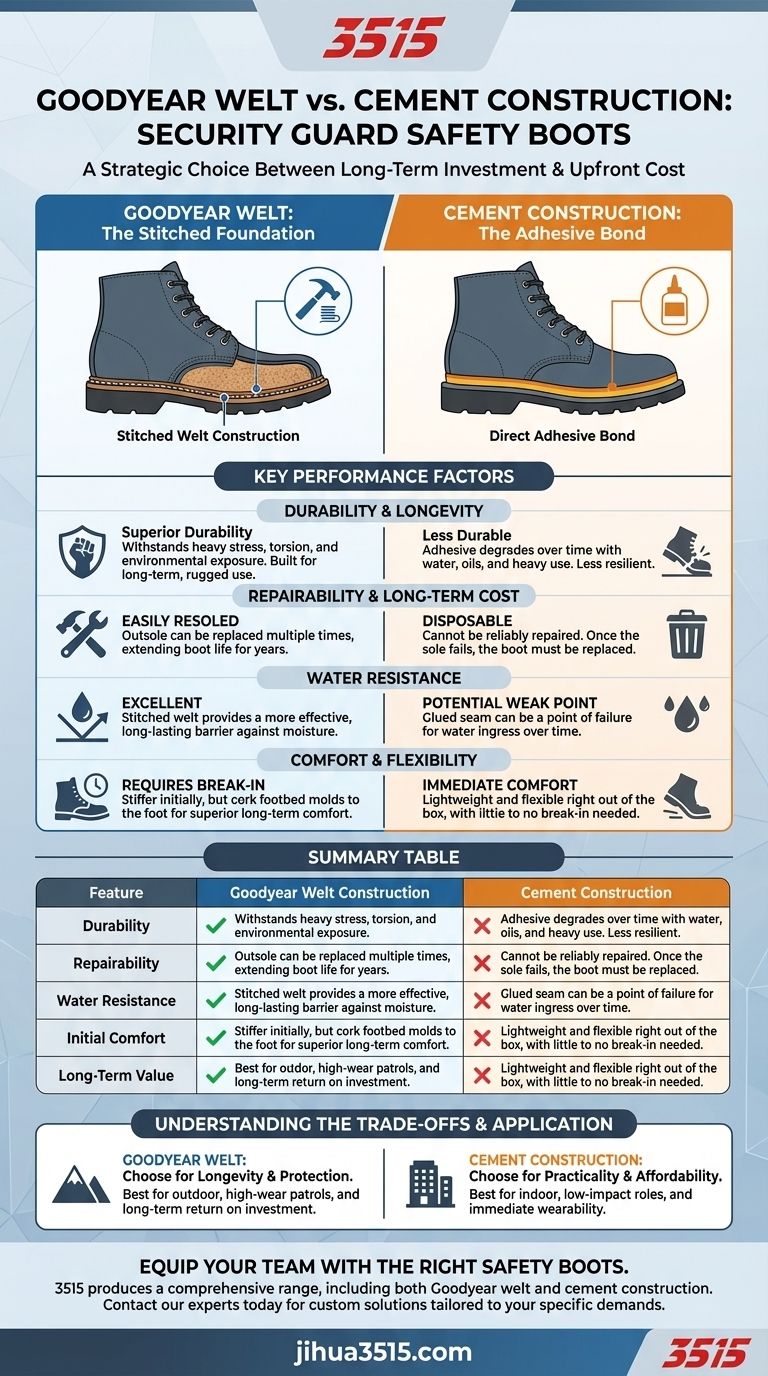

Key Performance Factors for Security Work

The construction method directly impacts the daily performance and long-term value of a safety boot, especially in a role that involves long hours on your feet.

Durability and Longevity

Goodyear welt is the undisputed winner for durability. The stitched construction creates a robust framework that can withstand immense stress, torsion, and environmental exposure far better than a glued bond.

Cement construction is less durable under constant, heavy use. The adhesive can degrade over time, especially with exposure to water, oils, or extreme temperatures, leading to sole separation.

Repairability and Long-Term Cost

This is the most significant difference. A Goodyear welted boot can be resoled multiple times. When the outsole wears down, a cobbler can simply cut the stitches holding it to the welt and attach a new sole without ever compromising the boot's upper.

A cemented boot is generally considered disposable. Once the sole detaches or wears through, it cannot be reliably repaired, meaning the entire boot must be replaced.

Water Resistance

The Goodyear welt provides a more effective barrier against water. The stitched welt creates a stronger, more complete seal around the edge of the boot, making it harder for moisture to penetrate from the ground up.

While many cemented boots have waterproof features, the glued seam remains a potential point of failure for water ingress over the life of the boot.

Comfort and Flexibility

Cement construction typically offers better initial comfort. These boots are lighter and more flexible right out of the box, requiring little to no break-in period.

Goodyear welted boots are stiffer at first and require a break-in period. However, over time, the cork footbed molds to the owner's foot, creating a custom, supportive fit that many find superior for long-term comfort.

Understanding the Trade-offs

Neither method is universally superior; the right choice depends on balancing priorities like budget, environment, and expected lifespan.

The Case for Goodyear Welt: An Investment in Safety

Choose Goodyear welt when the primary concerns are longevity and protection in rugged conditions. The higher initial cost is offset by the ability to resole the boots, extending their life for years and lowering the total cost of ownership over time.

The Case for Cement: Practicality and Affordability

Choose cement construction when the budget is the main driver or for less demanding roles. For guards working primarily indoors on predictable surfaces, the extreme durability of a welt may be unnecessary. The lightweight comfort is a significant advantage for those who prioritize immediate wearability.

How to Apply This to Your Role

Your decision should be based on the specific demands of the security assignment.

- If your primary focus is durability for outdoor or high-wear patrols: Choose Goodyear welt construction for its superior resilience and long-term value.

- If your primary focus is affordability and immediate comfort for indoor or low-impact roles: Cement construction is a practical and cost-effective solution.

- If your primary focus is long-term return on investment for a team: Goodyear welted boots, while more expensive upfront, often prove more economical by outlasting several pairs of cemented boots.

Ultimately, understanding the construction of a safety boot is the first step to ensuring you are equipped with footwear that truly supports and protects you through every shift.

Summary Table:

| Feature | Goodyear Welt Construction | Cement Construction |

|---|---|---|

| Durability | Superior, withstands heavy use | Good, but less resilient over time |

| Repairability | Can be resoled multiple times | Difficult or impossible to repair |

| Water Resistance | Excellent, strong stitched seal | Good, but glued seam is a weak point |

| Initial Comfort | Requires a break-in period | Lightweight and flexible out of the box |

| Long-Term Value | Higher upfront cost, lower cost over time | Lower upfront cost, replaced more often |

Equip Your Team with the Right Safety Boots

Choosing the correct boot construction is critical for the safety, comfort, and efficiency of your security personnel. As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including both durable Goodyear welt and comfortable cement construction methods.

We can help you select or custom-manufacture the perfect safety footwear solution tailored to the specific demands of your security teams, ensuring optimal protection and long-term value.

Ready to enhance your team's safety gear? Contact our experts today to discuss your requirements and receive a customized solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites