Ultimately, a boot's waterproofing is not the result of a single feature, but an integrated system. The construction method combines an internal waterproof membrane, specific outer materials, and a design that minimizes water entry points, like seams. This system approach is what separates a truly waterproof boot from one that is merely water-resistant.

The critical insight is that true waterproofing is built from the inside out. While surface treatments help, a boot's core waterproof performance is determined by its internal membrane, the quality of its seam sealing, and the inherent water-resistance of its sole and upper materials.

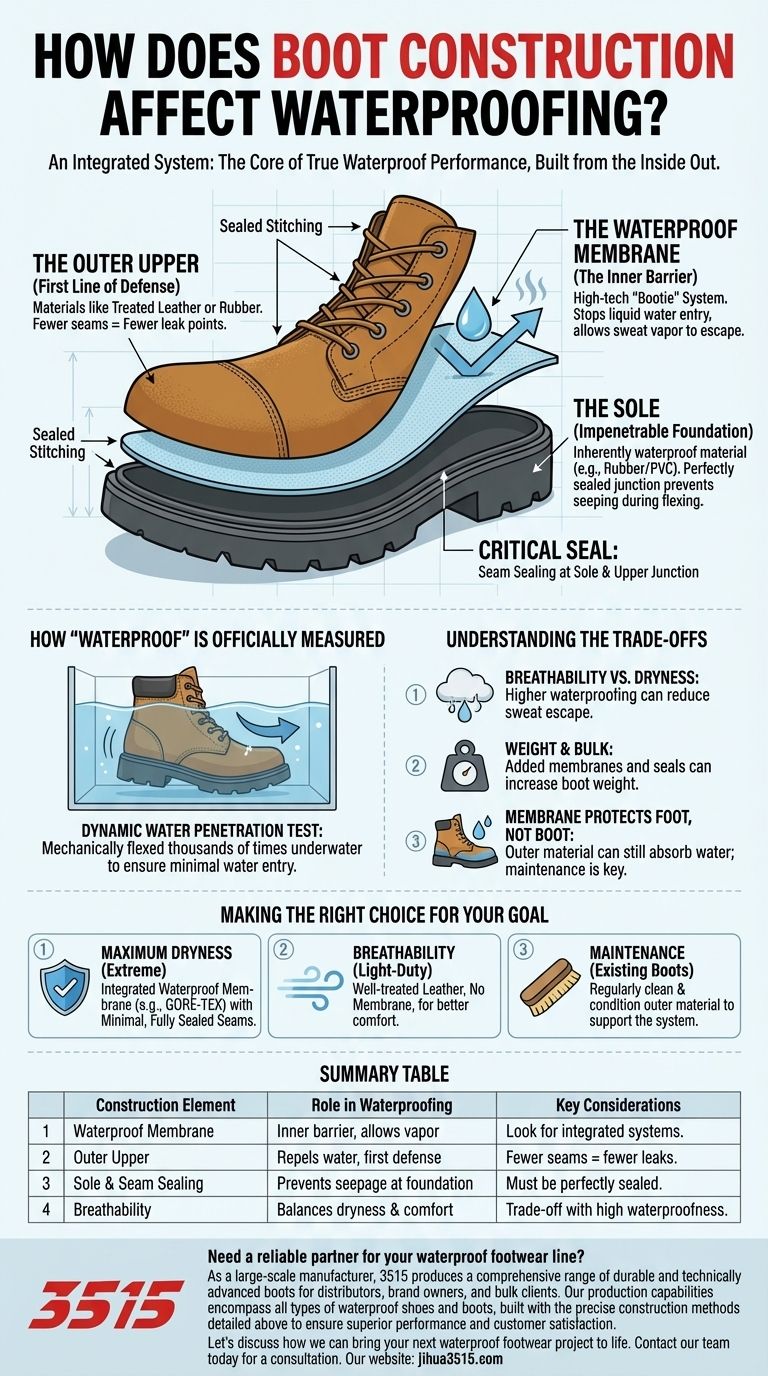

The Anatomy of a Waterproof Boot

To understand how a boot keeps water out, we need to look at its layers and construction points. A truly waterproof boot is a system where each component has a specific job.

The Waterproof Membrane: The Inner Barrier

The heart of modern waterproof footwear is a high-tech membrane, often called a "bootie," that is built into the boot's lining.

This system typically involves three layers: an inner lining to wick moisture away from your foot, a foam layer for cushioning, and the waterproof membrane itself. This membrane is a barrier that stops liquid water from getting in, but is designed to allow water vapor (sweat) to escape.

The Outer Upper: The First Line of Defense

The exterior of the boot, known as the upper, is the first component to face the elements. Uppers made of materials like rubber or treated leather offer significant water resistance on their own.

However, the design is just as important as the material. A boot with fewer seams and stitching points presents fewer potential weak spots where water can penetrate. Any seams that do exist on a waterproof boot must be sealed from the inside.

The Sole: The Impenetrable Foundation

The sole of a boot is its foundation and is typically made from inherently waterproof materials like rubber or PVC.

The critical construction detail is how the sole is attached to the upper. This junction must be perfectly sealed to prevent water from seeping in as the boot flexes and moves.

How "Waterproof" is Officially Measured

The term "waterproof" isn't just marketing—it's a standard that can be tested and verified.

The Dynamic Water Penetration Test

Boots claiming to be waterproof are subjected to a standardized "water flex test." In this test, the boot is submerged in water and mechanically flexed thousands of times over a set period.

To pass, the boot must allow less than a very small, specified amount of water to enter. This ensures the boot can withstand the real-world pressures of walking through wet environments.

Understanding the Trade-offs

Achieving total waterproofing involves compromises. Understanding these limitations is key to choosing the right footwear for your specific needs.

Breathability vs. Dryness

The same membrane that blocks water from entering can also make it harder for sweat to escape. This lack of breathability can lead to damp, uncomfortable feet, even if no external water gets in.

Weight and Bulk

Waterproof components, including membranes, sealed seams, and rubberized materials, add weight and rigidity to a boot. This can make them feel heavier and more cumbersome than non-waterproof alternatives.

The Membrane Protects Your Foot, Not the Boot

A common misunderstanding is that a waterproof membrane protects the entire boot. The membrane keeps your foot dry, but it does not stop the boot's outer material (like leather or fabric) from absorbing water. A waterlogged upper becomes heavy, loses breathability, and can degrade over time if not properly maintained.

Making the Right Choice for Your Goal

Selecting the right boot requires matching its construction to your intended use.

- If your primary focus is maximum dryness in extreme conditions: Seek out boots with an integrated waterproof membrane system (like GORE-TEX) and a design featuring minimal, fully sealed seams.

- If your primary focus is breathability for light-duty use: A boot made from well-treated leather without a membrane may offer better comfort and breathability for occasional encounters with moisture.

- If your primary focus is maintaining your existing boots: Remember that you must regularly clean and condition the outer material to maintain its water repellency, which supports the overall waterproof system.

Understanding how a boot is constructed empowers you to look past marketing claims and choose the right tool to keep your feet dry and comfortable.

Summary Table:

| Construction Element | Role in Waterproofing | Key Considerations |

|---|---|---|

| Waterproof Membrane | Inner barrier blocking water entry while allowing vapor (sweat) to escape. | Look for integrated systems like GORE-TEX. |

| Outer Upper | First line of defense; materials like treated leather or rubber repel water. | Fewer seams mean fewer potential leak points. |

| Sole & Seam Sealing | Prevents water from seeping in at the boot's foundation and stitching. | Must be perfectly sealed to withstand flexing. |

| Breathability | Balances dryness with comfort by managing internal moisture. | Higher waterproofing can mean lower breathability. |

Need a reliable partner for your waterproof footwear line?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and technically advanced boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof shoes and boots, built with the precise construction methods detailed above to ensure superior performance and customer satisfaction.

Let's discuss how we can bring your next waterproof footwear project to life. Contact our team today for a consultation.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job