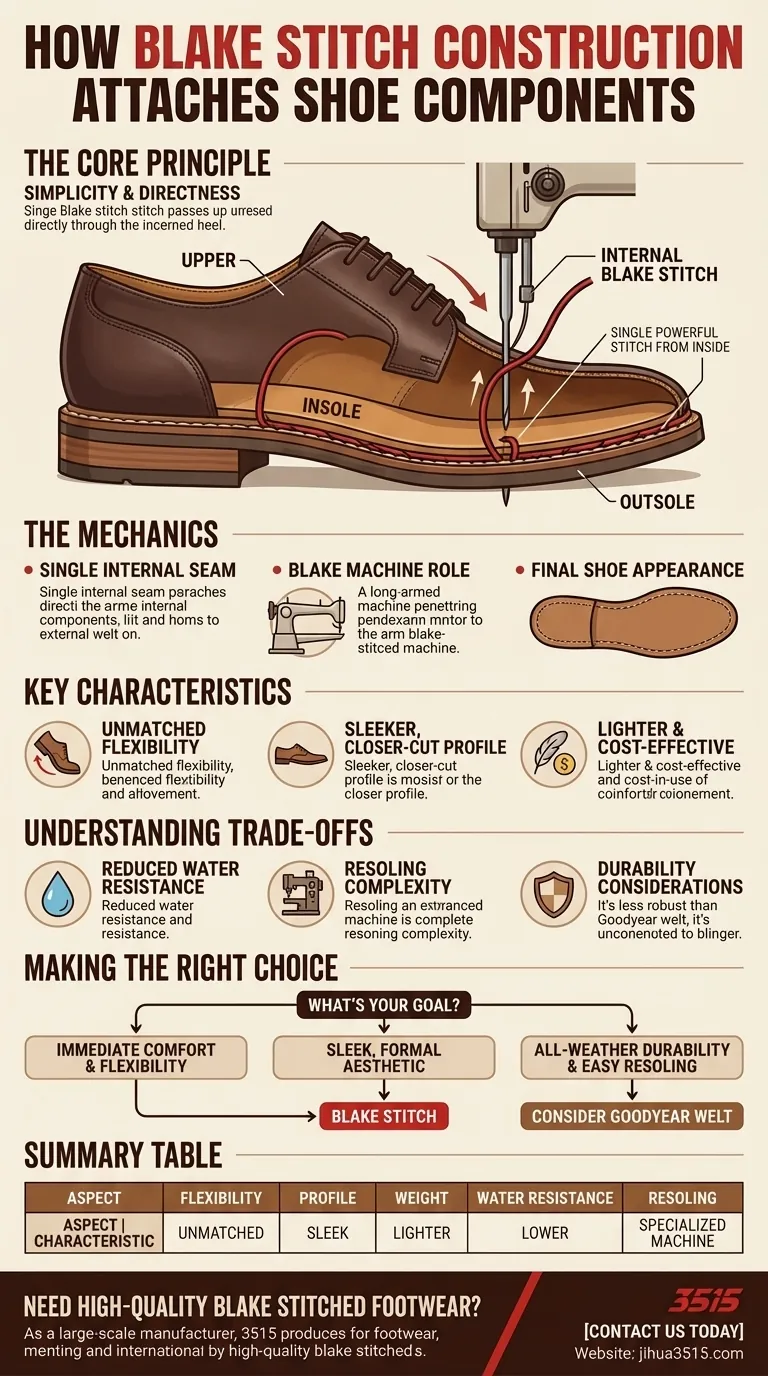

In Blake Stitch construction, the shoe's upper is attached directly to the outsole with a single, powerful stitch. This stitch is sewn from inside the shoe, passing through the insole and the upper before anchoring into the outsole, creating a clean and integrated build.

The core principle of the Blake Stitch is its simplicity and directness. By stitching the upper directly to the sole from the inside, it creates a shoe that is exceptionally flexible and has a sleek, close-trimmed profile.

The Mechanics of the Blake Stitch

The Blake Stitch method is defined by its unique internal seam. This construction technique is highly efficient and has a significant impact on the final shoe's look and feel.

The Single Internal Seam

The process involves lasting the shoe's upper over an insole and then using a special machine to sew a single line of stitching from the inside. This stitch simultaneously binds the insole, the upper, and the outsole together in one action.

The Role of a Blake Machine

This method requires a specific piece of equipment known as a Blake stitcher. This machine has a long arm that can reach inside the finished shoe to perform the stitching, a process that cannot be done by hand or with standard sewing equipment.

What You See on the Final Shoe

From the outside, you can identify a Blake Stitched shoe by looking at the sole. You will see the line of stitching running around the perimeter. However, unlike a Goodyear welt, there is no external welt or visible stitching on the edge of the sole connecting it to the upper.

Key Characteristics of a Blake Stitched Shoe

The direct, internal stitching gives Blake constructed footwear several distinct advantages, primarily related to comfort and aesthetics.

Unmatched Flexibility

Because there are fewer layers between your foot and the outsole, the shoe is remarkably flexible from the very first wear. The direct stitch allows the sole to bend easily with the natural movement of your foot, requiring little to no break-in period.

A Sleeker, Closer-Cut Profile

The absence of an external welt allows the outsole to be trimmed very close to the upper. This results in a sleeker, more elegant silhouette that is often favored for formal dress shoes like loafers and Italian-style designs.

Lighter and More Cost-Effective

The simpler construction process uses fewer materials and is less labor-intensive than more complex methods like the Goodyear welt. This generally results in a lighter shoe at a more accessible price point.

Understanding the Trade-offs

While effective, the Blake Stitch method has inherent limitations that are important to understand when choosing your footwear.

Reduced Water Resistance

The primary trade-off is water resistance. The line of stitching that passes directly from the outsole to the insole can act as a channel for water to wick into the shoe, making them less suitable for consistently wet environments.

Resoling Complexity

Blake Stitched shoes can be resoled, but it requires the same specialized Blake machine used to construct them. This means not all cobblers have the necessary equipment, potentially making repairs more difficult or costly to find.

Durability Considerations

A Blake Stitch is significantly more durable and secure than a simple glued (cemented) construction. However, it is generally considered less robust and water-tight than a Goodyear welt, which features an additional layer of material and external stitching.

Making the Right Choice for Your Goal

Selecting a shoe construction method depends entirely on your priorities. The Blake Stitch excels in specific scenarios where its unique benefits align with your needs.

- If your primary focus is immediate comfort and flexibility: A Blake Stitched shoe is an excellent choice, as its construction provides a supple feel right out of the box.

- If your primary focus is a sleek, formal aesthetic: The close-cut sole of the Blake Stitch offers a refined and elegant profile perfect for dress shoes.

- If your primary focus is all-weather durability and easy resoling: You may want to consider a Goodyear welt, which provides superior water resistance and is more widely serviceable.

Ultimately, understanding Blake Stitch construction empowers you to choose footwear that perfectly matches its intended purpose.

Summary Table:

| Aspect | Blake Stitch Characteristic |

|---|---|

| Flexibility | Unmatched, with little to no break-in period |

| Profile | Sleek and elegant, close-trimmed sole |

| Weight | Lighter than welted constructions |

| Water Resistance | Lower than Goodyear welted shoes |

| Resoling | Requires a specialized Blake machine |

Need high-quality Blake Stitched footwear for your brand or store?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including expertly crafted Blake Stitched models that offer superior comfort and a refined aesthetic.

Contact us today to discuss your manufacturing needs and bring exceptional footwear to your market!

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Factory Direct Wholesale Leather Comfort Shoes with Dial Closure

- Wholesale Leather Derby Shoes Manufacturer | Customizable Business & Dress Footwear

- Wholesale Leather Business Casual Shoes with Dial Closure - Manufacturer of Comfort Dress Sneakers

People Also Ask

- What is the function of compliant foam pads in the assessment of footwear? Master Sensory Integration & Stability

- Why is 3D human scanning technology necessary for high-precision biodynamic models? Enhance Your Model Accuracy Now

- Why is the toe of a western boot important? A Guide to Style, Fit, and Function

- How does the material selection differ between P-AFOs and E-AFOs? Choose Between Rigid Control and Dynamic Mobility

- Why is a Biplane X-ray Fluoroscopy system used to study foot bone movement? Achieve Unmatched Kinematic Precision

- Why is maintaining body temperature important for winter cycling? Conquer the Cold for Safe, High-Performance Rides

- What leather options are available for custom cowboy boots? Find the Perfect Material for Your Needs

- How do industrial automation and robotic systems enhance competitiveness? Drive High-Precision Footwear Manufacturing