Sustainable shoes conserve water primarily by replacing exceptionally thirsty raw materials, like conventional cotton, with eco-friendly alternatives. The production of traditional sneakers has a massive hidden water footprint, with a single kilogram of cotton—a common material for canvas shoes—requiring between 10,000 and 20,000 liters of water to grow. Sustainable footwear drastically reduces this by starting with materials that are either naturally low-water or bypass the agricultural stage altogether.

The core principle behind water conservation in sustainable footwear is material selection. By shifting away from water-intensive agriculture and processing, the environmental impact is minimized long before the shoe is ever assembled.

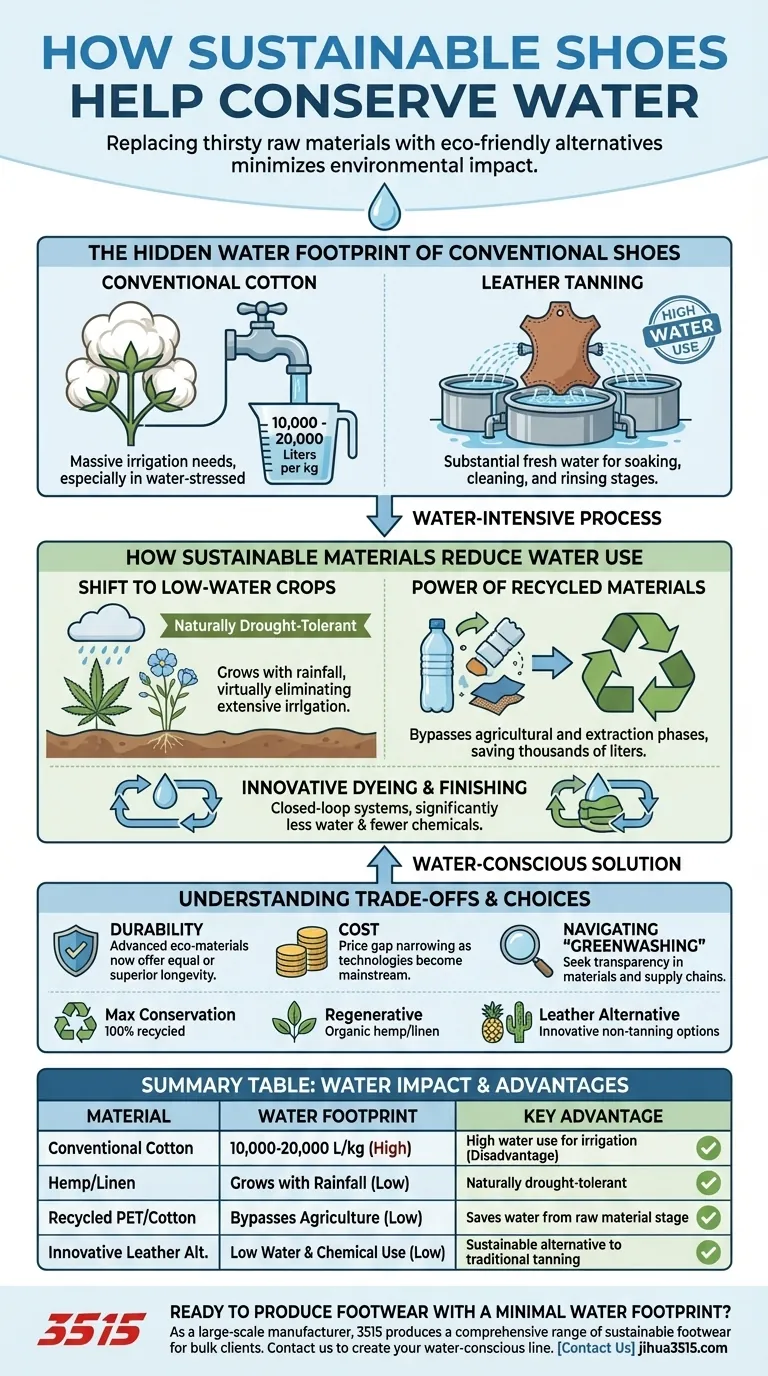

The Hidden Water Footprint of Conventional Shoes

To understand the solution, we must first appreciate the scale of the problem. The water used to manufacture a traditional shoe isn't primarily from the factory floor; it's embedded in the raw materials themselves.

The Thirst of Traditional Cotton

Conventional cotton is one of the most water-intensive crops in the world. Much of its cultivation relies on extensive irrigation, drawing massive amounts of water from rivers and groundwater sources, often in water-stressed regions.

The Impact of Leather Tanning

Leather production is another major consumer of water. The process of turning animal hide into finished leather involves numerous stages of soaking, cleaning, and rinsing, all of which require substantial volumes of fresh water.

How Sustainable Materials Drastically Reduce Water Use

Sustainable footwear brands tackle water consumption by fundamentally rethinking their material supply chain. They choose alternatives that are inherently more efficient.

Shifting to Low-Water Crops

Materials like hemp and linen are naturally drought-tolerant and can often be grown with rainfall alone, virtually eliminating the need for the extensive irrigation that cotton demands.

The Power of Recycled Materials

Using recycled materials, such as rPET from plastic bottles or recycled cotton, is one of the most effective strategies. This approach bypasses the water-intensive agricultural or raw material extraction phase entirely, saving thousands of liters per pair.

Innovative Dyeing and Finishing

Modern sustainable manufacturing also employs water-saving technologies. This includes closed-loop water systems in factories and advanced dyeing processes that use significantly less water and fewer chemicals than traditional methods.

Understanding the Trade-offs

While the environmental benefits are clear, it's important to approach sustainable footwear with a complete picture.

Durability and Performance

Some early-generation eco-materials did not offer the same longevity as their traditional counterparts. However, material science has advanced rapidly, and many leading sustainable brands now offer products with equal or superior durability.

Cost and Accessibility

The research and development required for innovative materials, along with smaller production scales, can sometimes result in a higher price point. This gap is narrowing as these technologies become more mainstream.

Navigating "Greenwashing"

The term "sustainable" is not regulated. It is crucial to look past marketing claims and seek transparency. Reputable brands will openly share details about their materials, supply chain, and water management practices.

Making an Informed Choice for Water Conservation

Your choice of footwear can have a tangible impact on global water resources. Use your goal to guide your decision.

- If your primary focus is maximum water conservation: Look for shoes made from 100% recycled materials, as this eliminates the agricultural water footprint.

- If your primary focus is supporting regenerative agriculture: Choose footwear made from certified organic, low-water crops like hemp or linen.

- If you are replacing a leather product: Opt for innovative leather alternatives derived from cactus, pineapple, or recycled synthetics, which have a far lower water and chemical impact than traditional tanning.

Ultimately, choosing sustainable footwear is a direct and powerful way to reduce your personal water footprint.

Summary Table:

| Material | Water Footprint | Key Advantage |

|---|---|---|

| Conventional Cotton | 10,000-20,000 L/kg | High water use for irrigation |

| Hemp/Linen | Grows with rainfall | Naturally drought-tolerant |

| Recycled PET/Cotton | Bypasses agriculture | Saves water from raw material stage |

| Innovative Leather Alternatives | Low water & chemical use | Sustainable alternative to traditional tanning |

Ready to produce footwear with a minimal water footprint?

As a large-scale manufacturer, 3515 produces a comprehensive range of sustainable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of eco-friendly shoes and boots, helping you meet the growing demand for water-conscious products.

Contact us today to discuss how we can help you create a sustainable and profitable footwear line.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Durable High-Traction Canvas Sneakers Wholesale & Custom Manufacturing

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

People Also Ask

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene