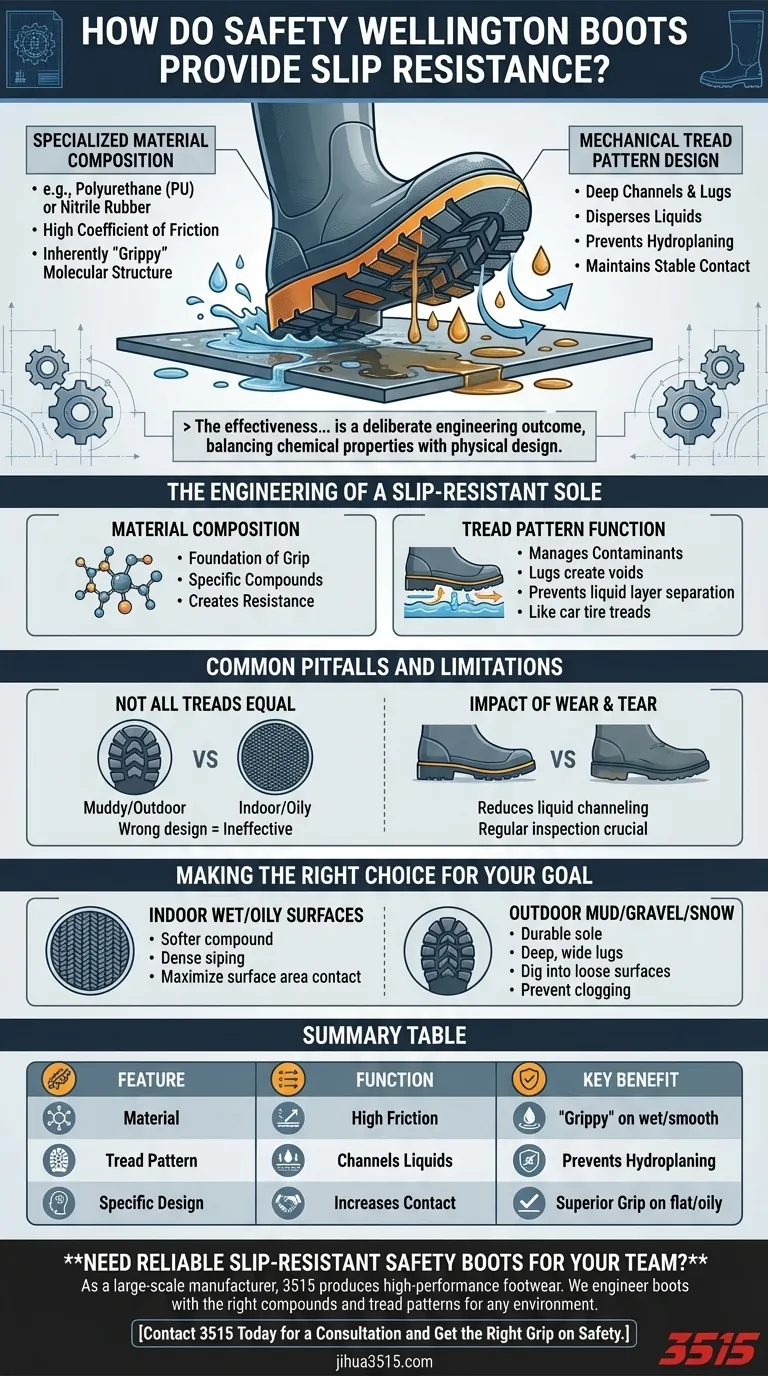

At its core, safety Wellington boots provide slip resistance through a combination of two critical design elements: the specialized material composition of the sole and the mechanical engineering of its tread pattern. These features work together to maximize grip and actively channel away liquids and contaminants from beneath the foot.

The effectiveness of a safety boot's slip resistance is not accidental. It is a deliberate engineering outcome, balancing the chemical properties of the sole's material with a physical design that clears a path for stable contact with the ground.

The Engineering of a Slip-Resistant Sole

A truly slip-resistant sole is a system where material and design are interdependent. Understanding how each component functions is key to appreciating its protective capability.

The Role of Material Composition

The foundation of grip is the material itself. Soles are made from specific compounds, often polyurethane (PU) or nitrile rubber, chosen for their high coefficient of friction.

This means the material is inherently "grippy" at a molecular level, creating more resistance against a smooth or wet surface compared to standard footwear.

The Function of Tread Pattern

The tread pattern is the mechanical part of the system. Its primary job is to manage contaminants like water, oil, or mud, as mentioned in the references.

Deep channels, or lugs, create voids that allow liquids to be squeezed out from under the sole's contact patch. This prevents a phenomenon known as hydroplaning, where a layer of liquid separates the boot from the floor, causing a complete loss of traction.

Think of it like the treads on a car tire in the rain. Without the channels to disperse water, the tire would simply skim over the surface.

Common Pitfalls and Limitations

Even the most advanced safety boot is part of a larger safety ecosystem. Relying on the boot alone without understanding its limitations can lead to a false sense of security.

Not All Treads Are Created Equal

A sole designed for muddy, uneven outdoor terrain will have deep, widely-spaced lugs to bite into the ground. This design, however, is less effective on a smooth, oily factory floor.

Conversely, a sole with a fine, dense pattern designed for dispersing oil on a flat surface would quickly become clogged and useless in a muddy field.

The Impact of Wear and Tear

Slip resistance is not a permanent feature. As the sole wears down, the sharp edges of the tread become rounded and the channels become shallower.

This significantly reduces the sole's ability to channel away liquids and maintain its grip. Regular inspection of footwear for wear is a critical, and often overlooked, safety practice.

Making the Right Choice for Your Goal

Selecting the correct boot requires matching its design to the specific hazards of your environment.

- If your primary focus is indoor wet or oily surfaces: Prioritize boots with a softer sole compound and a dense pattern of fine channels (siping) to maximize surface area contact and liquid dispersal.

- If your primary focus is outdoor mud, gravel, or snow: Look for a durable sole with deep, aggressive, and widely-spaced lugs that can dig into loose surfaces and prevent clogging.

Ultimately, understanding how a boot generates grip empowers you to select the right tool for the job, turning footwear from a simple requirement into an active safety measure.

Summary Table:

| Feature | Function | Key Benefit |

|---|---|---|

| Material (e.g., Nitrile Rubber) | High coefficient of friction | Inherently "grippy" on wet/smooth surfaces |

| Tread Pattern (Lugs & Channels) | Channels away liquids and contaminants | Prevents hydroplaning and maintains ground contact |

| Specific Design (e.g., Siping) | Increases surface area contact | Superior grip on flat, oily indoor floors |

Need Reliable Slip-Resistant Safety Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance safety footwear for distributors, brand owners, and bulk clients. We engineer boots with precisely the right sole compounds and tread patterns to protect your workforce in any environment—from oily factory floors to muddy outdoor sites.

Let's equip your team with boots that provide active safety. Contact 3515 today for a consultation and get the right grip on safety.

Visual Guide

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Durable Spiked Camouflage Boots Wholesale & Factory Production

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What regular maintenance checks should be performed on safety boots? A Daily Safety Checklist

- What is ASTM International and what does it do? A Guide to Global Standards

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What organization sets national standards for workplace safety in the U.S.? OSHA's Role Explained

- How does ASTM differ from ANSI? Navigating the U.S. Standards System for Compliance