In essence, safety shoes protect against chemical exposure through the strategic use of resistant materials. These materials, such as specialized rubbers, PVC, and neoprene, are engineered to form an impermeable barrier that prevents corrosive or hazardous liquids from reaching the skin, thereby preventing chemical burns and other injuries.

The core principle of chemical protection in safety footwear isn't about a single feature, but about constructing the entire shoe—especially the outsole and upper—from materials scientifically chosen for their inability to be degraded or penetrated by specific types of chemicals.

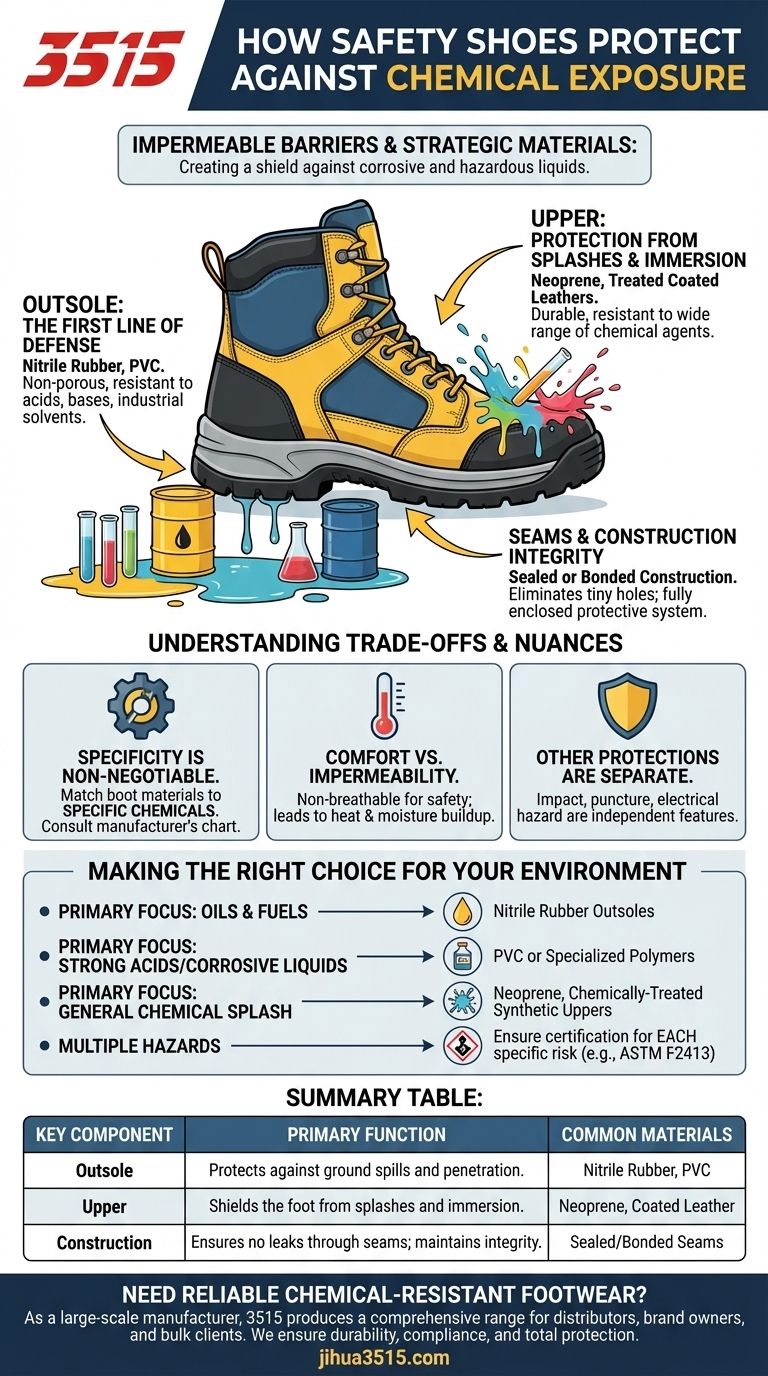

How Chemical Resistance is Built into Safety Footwear

The effectiveness of a safety shoe against chemical hazards is determined entirely by the materials it's made from. A standard leather boot offers minimal protection, while a specialized boot is designed at a molecular level to repel harmful substances.

The Role of Outsole Materials

The outsole is the first line of defense, making direct contact with chemical spills on the ground.

Materials like nitrile rubber and polyvinyl chloride (PVC) are common choices. They are non-porous and do not react with many acids, bases, and industrial solvents, preventing the chemical from eating through the sole.

The Importance of the Upper Material

The upper part of the shoe protects the rest of the foot from splashes and immersion.

Specialized boots often use materials like neoprene or treated, coated leathers. These materials are selected for their durability and resistance to a wide range of chemical agents, ensuring a complete protective seal around the foot.

Seams and Construction Integrity

A shoe can be made from the best materials, but it will fail if the seams leak.

High-quality chemical-resistant footwear often uses sealed or bonded construction rather than traditional stitching. This eliminates tiny holes where liquids could penetrate, ensuring the boot remains a fully enclosed protective system.

Understanding the Trade-offs and Nuances

Not all "chemical-resistant" footwear is created equal. The term is broad, and selecting the wrong type can provide a false sense of security.

Specificity is Non-Negotiable

A boot resistant to strong acids may not offer protection against organic solvents.

It is crucial to match the boot's material specifications to the specific chemicals present in your workplace. Always consult the manufacturer's chemical resistance chart for definitive guidance.

Comfort and Breathability vs. Impermeability

The very properties that make a boot impermeable to chemicals also make it non-breathable.

This can lead to significant heat and moisture buildup inside the boot, causing discomfort and potential skin issues. This is a necessary trade-off for safety in hazardous environments.

Other Protective Features Are Separate

Chemical resistance is just one potential feature of a safety shoe.

Protection against impact (steel toe), puncture (midsole plate), or electrical hazards are independent features. A chemical-resistant boot does not automatically provide these other protections unless explicitly stated.

Making the Right Choice for Your Environment

Your selection process must be driven by a precise understanding of the hazards you face. A thorough risk assessment of your workplace is the only way to ensure proper protection.

- If your primary focus is protection against oils and fuels: Look for footwear with nitrile rubber outsoles, which offer excellent resistance to hydrocarbons.

- If your primary focus is handling strong acids or corrosive liquids: Choose boots made from PVC or specialized polymers designed specifically for acid resistance.

- If your primary focus is general-purpose chemical splash protection: Neoprene or chemically-treated synthetic uppers offer a good balance of flexibility and broad resistance.

- If your environment has multiple hazards: Ensure your chosen footwear is certified for each specific risk, such as chemical resistance, impact protection (ASTM F2413), and electrical hazard (EH) rating.

Ultimately, the right safety shoe acts as a critical piece of personal protective equipment, engineered to stand between you and a potentially severe chemical injury.

Summary Table:

| Key Component | Primary Function | Common Materials |

|---|---|---|

| Outsole | Protects against ground spills and penetration. | Nitrile Rubber, PVC |

| Upper | Shields the foot from splashes and immersion. | Neoprene, Coated Leather |

| Construction | Ensures no leaks through seams; maintains integrity. | Sealed/Bonded Seams |

Need Reliable Chemical-Resistant Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of chemical-resistant shoes and boots, designed with the right materials—like nitrile rubber and PVC—to match your specific workplace hazards.

We ensure durability, compliance, and total protection for your workforce. Let's discuss your requirements and get a customized solution. Contact our experts today for a quote!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What are the primary protective functions of professional-grade safety shoes? Enhance Safety in Heavy Industry

- Why are safety shoes critical for compliance? Essential for Risk Mitigation & Legal Protection

- How does RFID technology improve Supply Chain Agility in safety shoe manufacturing? Master Real-Time Boot Production

- Why are high-precision infrared motion capture systems used for gear? Proven Biomechanical Data for Protective Footwear

- How do heat-resistant safety shoes contribute to safety near 900-degree furnaces? Maximize Thermal Protection

- Why is it important to check the certification of safety boots? Ensure Legal Compliance & Worker Safety

- What types of insoles are used in safety boots, and how do they improve comfort? Choose the Right Support for Your Job

- How does lightweight safety shoe technology reduce waist and shoulder injuries? Expert Ergonomic Insights