At their core, non-slip shoes differ from regular shoes in their sole, which is specifically engineered with unique materials and tread patterns to maximize friction. This design provides a superior grip on wet, oily, or otherwise slippery surfaces where regular shoes would fail.

While they may look similar to regular footwear, non-slip shoes are a specialized safety system. Their effectiveness comes from a deliberate combination of soft sole materials and intricate tread designs engineered to channel away liquids and maintain contact with the ground.

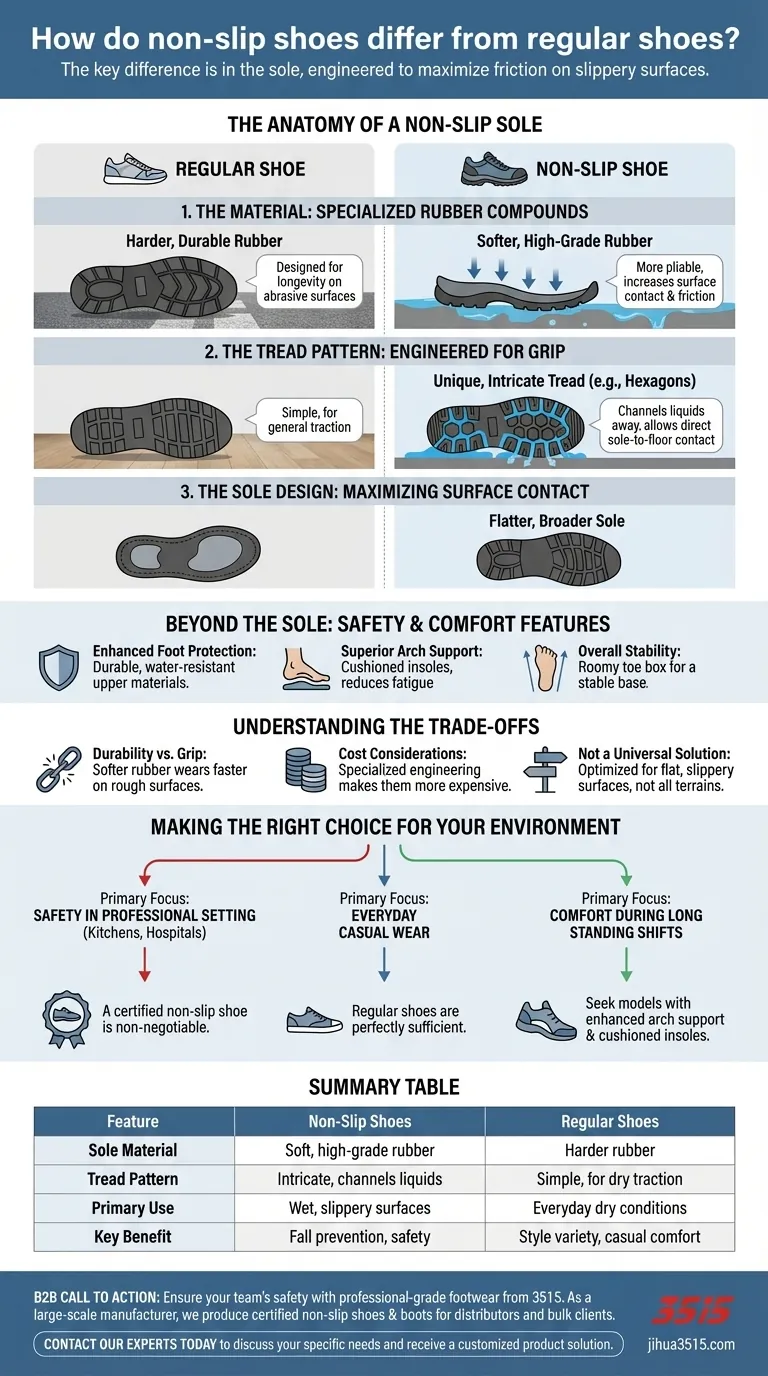

The Anatomy of a Non-Slip Sole

The primary distinction lies in how the bottom of the shoe is constructed. It's not a single feature but a combination of elements working together to prevent falls.

The Material: Specialized Rubber Compounds

Regular shoes often use harder, more durable rubber compounds designed for longevity on abrasive surfaces like pavement.

Non-slip shoes, however, use a softer, higher-grade rubber for their outsoles. This softer material is more pliable, allowing it to conform better to microscopic imperfections in a floor, thereby increasing the surface area of contact and creating more friction.

The Tread Pattern: Engineered for Grip

The tread on a regular shoe is typically designed for general traction on dry surfaces.

A non-slip shoe features a unique, intricate tread pattern, often composed of small, hexagonal or circular shapes. This design serves a critical purpose: it actively channels liquids like water and oil away from the bottom of the shoe. By moving the liquid out of the way, the rubber sole can make direct contact with the floor, which is essential for maintaining grip.

The Sole Design: Maximizing Surface Contact

The overall shape of the sole on non-slip shoes is generally flatter and broader. This design helps to distribute your weight evenly across the entire sole, maximizing the amount of the shoe that is in contact with the ground at any given moment.

Beyond the Sole: Features for Safety and Comfort

While the sole is the main event, true slip-resistant footwear incorporates other features designed for demanding environments.

Enhanced Foot Protection

Many non-slip shoes are designed for professional settings and are built with more durable, water-resistant upper materials. This protects the foot not only from slips but also from spills and impacts.

Superior Arch Support

Recognizing that these shoes are often worn for long shifts, manufacturers frequently include cushioned insoles and better arch support. This reduces fatigue and improves comfort and stability over many hours of standing or walking.

Overall Stability

Features like a roomy toe box allow your toes to spread out naturally. This provides a wider, more stable base for balance, further reducing the risk of a fall.

Understanding the Trade-offs

Choosing non-slip footwear involves recognizing its specific purpose and limitations.

Durability vs. Grip

The softer rubber that provides excellent grip is also less resistant to abrasion. A non-slip shoe worn constantly on rough surfaces like concrete may wear out faster than a regular shoe with a harder sole.

Cost Considerations

The specialized materials, research, and engineering that go into creating an effective non-slip shoe often make them more expensive than their standard counterparts.

Not a Universal Solution

Non-slip shoes are optimized for flat, slippery surfaces like kitchen tiles or polished concrete. They are not a replacement for hiking boots on a trail or running shoes on a track, where different types of tread are required.

Making the Right Choice for Your Environment

Your decision should be based entirely on the conditions you expect to face.

- If your primary focus is safety in a professional setting (kitchens, hospitals): A certified non-slip shoe is non-negotiable; its specialized sole is essential for preventing workplace accidents.

- If your primary focus is everyday casual wear: Regular shoes offer a wider variety of styles and are perfectly sufficient for typical, dry walking conditions.

- If your primary focus is comfort during long standing shifts: Seek out non-slip models that specifically advertise enhanced arch support and cushioned insoles to reduce fatigue.

Ultimately, choosing the right shoe is about matching the engineering of the sole to the demands of your environment.

Summary Table:

| Feature | Non-Slip Shoes | Regular Shoes |

|---|---|---|

| Sole Material | Soft, high-grade rubber for superior grip | Harder rubber for general durability |

| Tread Pattern | Intricate (e.g., hexagons) to channel liquids away | Simple, for general dry traction |

| Primary Use | Wet, oily, slippery surfaces (e.g., kitchens, hospitals) | Everyday dry conditions |

| Key Benefit | Fall prevention and workplace safety | Style variety and casual comfort |

Ensure your team's safety with professional-grade footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified non-slip shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, engineered with the specialized soles, durable materials, and superior comfort features detailed above.

Protect your workforce and reduce slip-related incidents. Contact our experts today to discuss your specific needs and receive a customized product solution.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today