Motorcycle boots resist abrasion through a combination of carefully selected materials, robust construction methods, and a secure fit designed to withstand the intense forces of a slide on pavement.

True abrasion resistance in a motorcycle boot is not a single feature but a complete system. It relies on the right material, like full-grain leather, being held together by durable stitching and, most importantly, being secured to your foot so it can do its job in a crash.

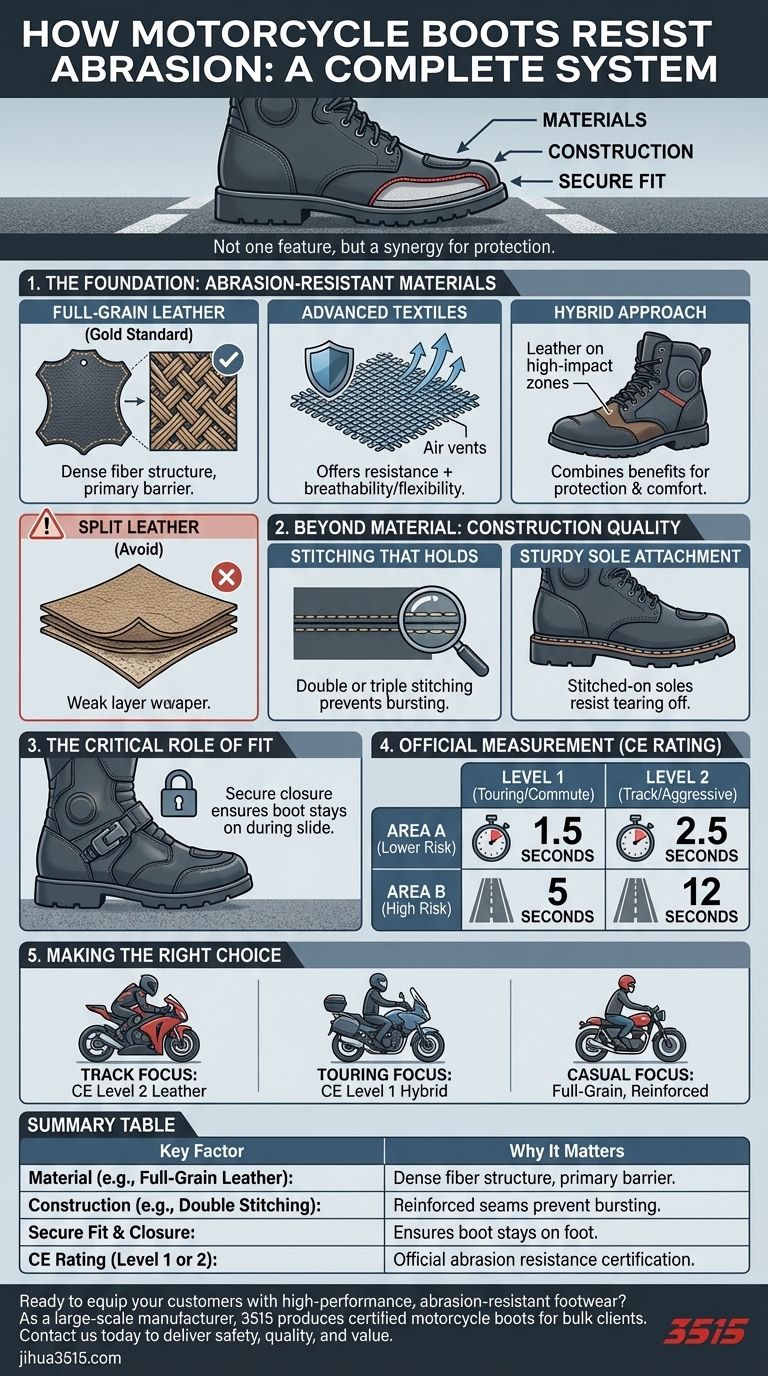

The Foundation: Abrasion-Resistant Materials

The first line of defense against the road is the material the boot is made from. The choice of material dictates not only the level of protection but also the boot's comfort and longevity.

Full-Grain Leather: The Gold Standard

Full-grain or top-grain leather is the benchmark for abrasion resistance. Its dense, uninterrupted fiber structure provides the best protection against being worn away by pavement.

In contrast, split leather, which is a lower-quality cut, is ineffective in a crash and should be avoided for protective gear.

Advanced Textiles and Synthetics

Modern boots often incorporate advanced textiles or synthetic blends. These materials can offer excellent abrasion resistance while providing benefits like improved breathability, flexibility, and reduced weight compared to traditional leather.

The Hybrid Approach

Many of the best boots combine materials to maximize their benefits. You will often find a leather chassis for primary protection, with textile panels in lower-impact areas to increase comfort and airflow.

Beyond Material: The Importance of Construction

A boot made from the strongest material will fail if it's not held together properly. The construction quality is just as critical as the material itself.

Stitching That Holds

During a slide, seams are major failure points. Look for boots with double or triple stitching in critical areas. This redundancy ensures the boot won't burst open on impact, keeping the protective material between you and the road.

A Sturdy Sole

The sole must be securely attached to the boot's upper. Stitched-on soles are far more durable and resistant to being torn off in a crash compared to those that are merely glued on.

The Critical Role of Fit

The most protective boot in the world is useless if it comes off your foot. A proper, secure fit with a reliable closure system is a non-negotiable safety feature that ensures the boot stays in place to protect you during a slide.

How Protection is Officially Measured

To standardize safety, motorcycle boots can be certified to a specific performance level. This rating tells you exactly how much abrasion the boot has been tested to withstand.

Areas of Protection

Testers divide the boot into two zones. Area A includes parts with lower risk, like the sole and the front/back of the foot. Area B covers the sides and other high-risk areas that are more likely to endure a long slide.

Level 1 vs. Level 2 Resistance

Material samples from each area are subjected to an abrasion machine until a hole forms.

- Level 1 requires the material to last 1.5 seconds in Area A and 5 seconds in Area B.

- Level 2 is the higher standard, requiring 2.5 seconds in Area A and a much more demanding 12 seconds in Area B.

Making the Right Choice for Your Riding

Your ideal boot depends on balancing maximum protection with the demands of your specific riding style.

- If your primary focus is track riding or aggressive street use: Seek out a boot with a certified CE Level 2 rating, primarily made of full-grain leather with extensive external armor.

- If your primary focus is touring or daily commuting: A hybrid leather-and-textile boot with a CE Level 1 rating offers an excellent balance of certified protection, comfort, and weather resistance.

- If your primary focus is casual riding: Prioritize boots made from full-grain leather with double stitching and full ankle coverage, as these construction fundamentals offer a significant safety upgrade over standard footwear.

Ultimately, understanding these principles of material and construction empowers you to choose a boot that protects you not just by chance, but by design.

Summary Table:

| Key Factor | Why It Matters |

|---|---|

| Material (e.g., Full-Grain Leather) | Dense fiber structure provides the primary barrier against pavement wear. |

| Construction (e.g., Double Stitching) | Reinforced seams prevent the boot from bursting open during a slide. |

| Secure Fit & Closure | Ensures the boot stays on your foot to provide protection when you need it most. |

| CE Rating (Level 1 or 2) | Official certification that quantifies abrasion resistance based on rigorous testing. |

Ready to equip your customers with high-performance, abrasion-resistant footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified motorcycle boots for distributors, brand owners, and bulk clients. Our expertise in selecting premium materials and employing durable construction techniques ensures every pair offers superior protection by design.

Contact us today to discuss your specific needs and discover how we can deliver safety, quality, and value to your business.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What makes western boots unique? Unpacking the Equestrian DNA of an Icon

- How does understanding foot shape help in choosing outdoor shoes? Find Your Perfect Fit for Comfort & Performance

- What are dirt bike boots and their primary features? Essential Off-Road Motorcycle Footwear Explained

- How does the sole design of winter cycling shoes differ from summer shoes? Grip, Flexibility & Warmth Explained

- How do specialized boot features improve hunting performance? Boost Your Endurance & Success

- How should cost be considered when purchasing riding boots? Invest in Safety, Durability & Performance

- What are the advantages of sports sandals for hiking? Maximize Comfort on Hot, Wet Trails

- Is it worth buying snow boots? Essential Safety & Warmth for Winter