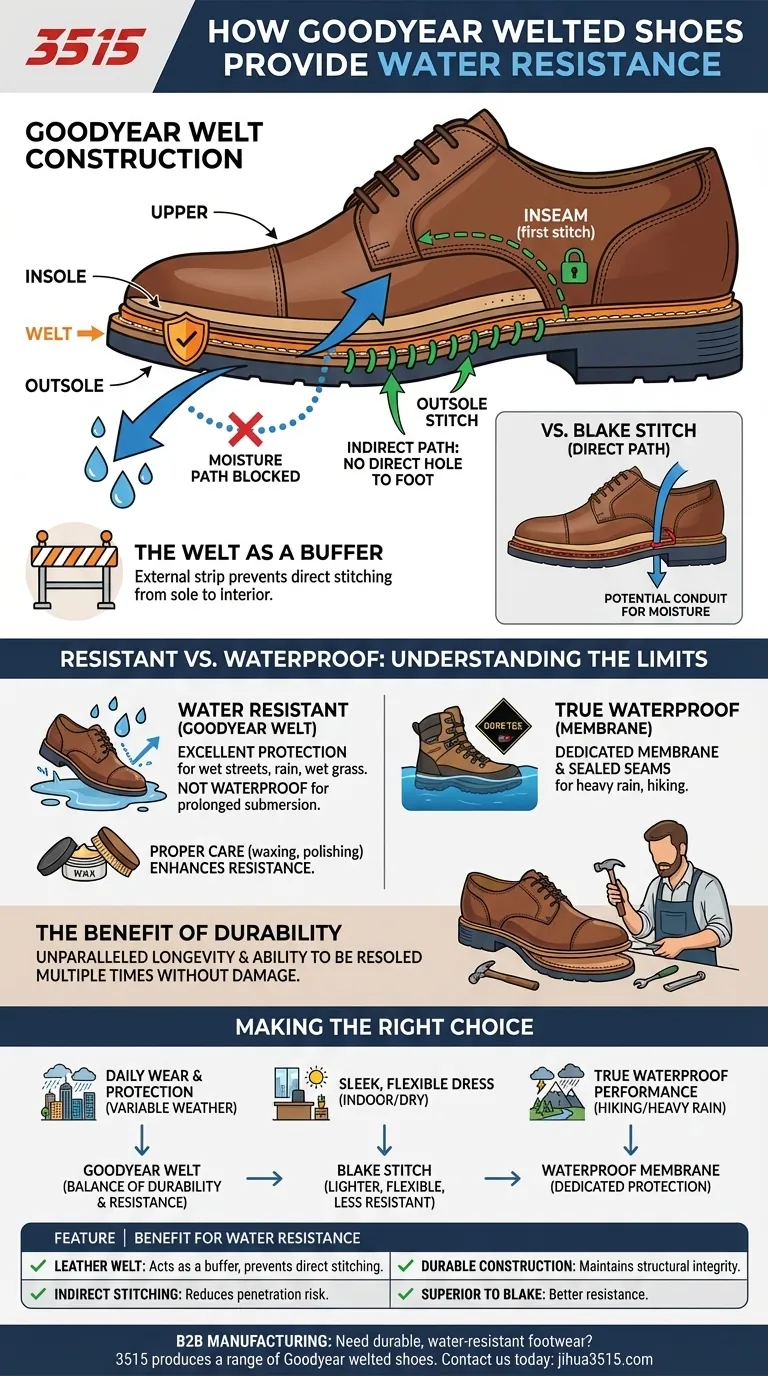

At its core, Goodyear welt construction provides water resistance by creating an indirect path for moisture. Unlike simpler methods where stitches run directly from the sole into the shoe's interior, a Goodyear welt uses a separate strip of leather—the welt—as a buffer. This means the primary stitch that attaches the sole is on the outside of the shoe, never penetrating the insole your foot rests on.

The critical design feature for water resistance is the welt itself. By stitching the upper to this external leather strip, and then stitching the sole to that same strip, the construction avoids creating a direct channel for water to wick up from the ground into the shoe.

The Anatomy of a Water-Resistant Welt

To understand why this construction is so effective, it's helpful to visualize the layers and the two key stitches that hold everything together.

The Role of the Welt

The welt is a durable strip of leather that runs along the perimeter of the shoe's sole. Its entire purpose is to act as a point of connection between the upper part of the shoe and the outsole, preventing them from being stitched directly together.

The First Stitch: The Inseam

An initial, hidden stitch called the inseam connects the upper, the shoe lining, and the insole to the welt. This stitch occurs on the inside of the construction, creating a secure foundation.

The Second Stitch: The Outsole Stitch

A second, visible stitch runs through the welt and attaches the outsole. This is the stitch you can see when you look at the top edge of the sole. Because this stitch only goes through the welt and outsole, it doesn't create a hole leading to the interior of the shoe.

Why This Indirect Path Matters

This two-stage stitching process creates a much more difficult path for water. For moisture to penetrate, it must first get past the sealed edge of the outsole, seep through the exterior stitching, navigate through the welt itself, and then find a way past the inseam. This is a significant improvement over a Blake stitch, where a single stitch runs directly from the outsole to the insole, acting as a potential conduit for moisture.

Understanding the Trade-offs: Resistant vs. Waterproof

While highly effective, it is crucial to understand the distinction between water-resistant and waterproof. A Goodyear welt offers a high degree of protection, but it has its limits.

The Limits of Resistance

A Goodyear welted shoe will protect your feet excellently during a walk through damp city streets or wet grass. However, it is not waterproof. During prolonged exposure or submersion, water can eventually work its way through the leather and seams.

The Need for Proper Care

The references note that additional treatments enhance protection. Regular waxing of the soles and polishing the uppers helps maintain the leather's natural resistance to water, preserving the shoe's integrity and longevity.

The Benefit of Durability

The primary advantage of this labor-intensive method is unparalleled durability and the ability to be resoled multiple times. Because the outsole is stitched to the welt and not the upper, a cobbler can easily remove the old sole and attach a new one without compromising the shoe's structure.

Making the Right Choice for Your Needs

A Goodyear welt is a mark of quality construction, but understanding its specific benefits allows you to choose the right footwear for your goal.

- If your primary focus is durability and protection for daily wear in variable weather: A Goodyear welt is one of the best choices available for its balance of longevity and water resistance.

- If your primary focus is a sleek, flexible dress shoe for indoor or dry conditions: A Blake-stitched shoe may be preferable for its lighter weight and flexibility, though it sacrifices water resistance.

- If your primary focus is true waterproof performance for hiking or heavy rain: You should look for footwear with a dedicated waterproof membrane (like Gore-Tex) and sealed-seam construction.

Ultimately, understanding how a shoe is constructed empowers you to invest in footwear that truly serves its intended purpose.

Summary Table:

| Feature | Benefit for Water Resistance |

|---|---|

| Leather Welt | Acts as a buffer, preventing direct stitching from sole to interior. |

| Indirect Stitching Path | Moisture must navigate multiple layers, reducing penetration risk. |

| Durable Construction | Allows for multiple resoles, maintaining structural integrity over time. |

| Comparable to Blake Stitch | Superior resistance due to the welt's protective role. |

Need durable, water-resistant footwear for your customers? As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear welted shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities ensure top-tier construction that balances longevity, weather protection, and style. Let us help you deliver premium footwear that stands up to the elements. Contact us today to discuss your manufacturing needs!

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

People Also Ask

- What is the primary function of color-coded TPM labels in footwear manufacturing? Enhance Factory Efficiency

- How are pH meters and water extraction used for EVA footwear safety? Ensuring Skin-Friendly Chemical Standards

- What roles do industrial-grade corrugated boxes and wrapping paper play in footwear delivery? Protect Your Brand Value

- Why is the use of non-stretch measuring tapes for waist monitoring necessary? Ensure Safety for Tactical Personnel

- Why is it important to invest in good quality shoes? Protect Your Health, Wallet, and Style

- What additional clothing items are recommended for cold weather travel? Build Your Ultimate Layering System

- How should one choose between water-resistant and waterproof footwear? Match Protection to Your Environment

- Why should footwear marketing strategies incorporate a cross-economic comparative analysis? Drive Global Growth Now