At their core, electrical hazard (EH) boots function as insulators for your body. They are built with soles and heels made from non-conductive materials like rubber and specialized compounds. This design stops your feet from making an electrical connection to the ground, preventing your body from becoming the path of least resistance for a dangerous current.

The central purpose of EH-rated footwear is to provide a secondary source of protection against accidental electrical shock. Its effectiveness, however, is critically dependent on maintaining a dry, intact barrier between you and the ground.

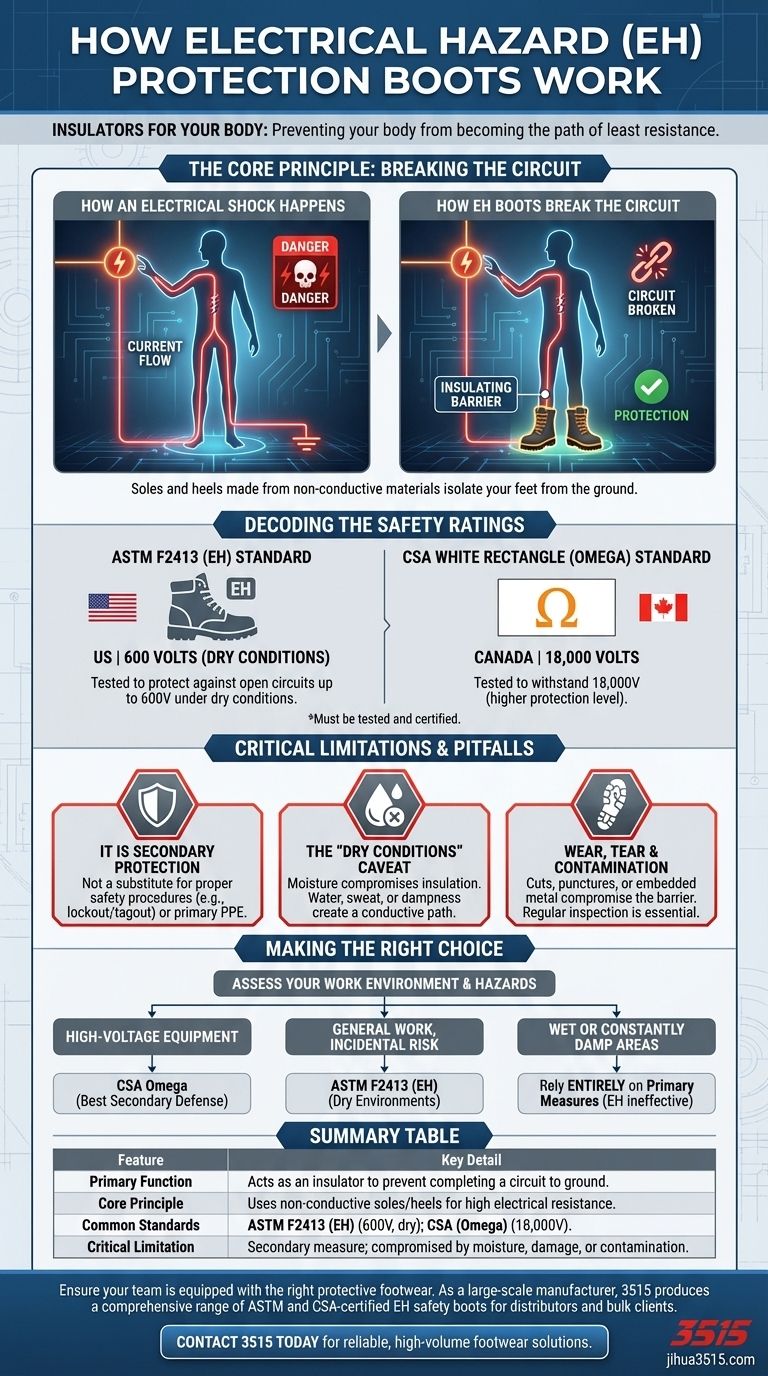

The Core Principle: Breaking the Circuit

To understand how EH boots work, you first need to understand how an electrical shock occurs. It’s not just about touching a live wire; it’s about completing a circuit.

How an Electrical Shock Happens

An electrical shock requires a complete path for electricity to flow. Often, this happens when a person makes contact with a live electrical source while also being in contact with the ground. In this scenario, the body becomes a conductor, allowing electricity to pass through it to the earth.

The Role of Insulation

EH boots are designed to break this circuit. The entire sole and heel are constructed from materials with very high electrical resistance. This effectively isolates your feet from the ground.

If you accidentally step on or touch a live circuit, the insulating sole prevents electricity from using your body as a pathway to the ground, significantly reducing the risk of a life-threatening shock.

Decoding the Safety Ratings

Not all safety boots offer electrical protection. This is a specific rating that must be tested and certified by a standards organization.

The ASTM F2413 (EH) Standard

In the United States, the most common rating is from the American Society for Testing and Materials. Boots meeting the ASTM F2413 standard are tested to protect against open circuits up to 600 volts under dry conditions. This rating is typically indicated by an "EH" marking on the boot's tongue or label.

The CSA White Rectangle (Omega) Standard

In Canada, the Canadian Standards Association (CSA) uses a distinct symbol: a white rectangle with the Greek letter omega (Ω). This indicates a much higher level of protection, tested to withstand 18,000 volts with a leakage current not exceeding 1mA for 60 seconds.

Critical Limitations and Common Pitfalls

Understanding what EH boots cannot do is just as important as knowing what they can. Relying on them improperly creates a false sense of security.

It Is Secondary Protection

EH boots are considered a secondary source of protection. They are not a substitute for proper safety procedures like lockout/tagout, using insulated tools, or wearing appropriate primary protective equipment like rubber insulating gloves.

The "Dry Conditions" Caveat

This is the single most critical limitation. The insulating properties of EH boots are severely compromised by moisture. Water, excessive sweat, or working in a damp location can create a conductive path and render the EH protection ineffective.

Wear, Tear, and Contamination

The insulating sole must remain intact to function correctly. Any deep cuts, punctures, or embedded conductive materials (like metal shavings) can compromise the boot's protective barrier. Regular inspection is essential for safety.

Making the Right Choice for Your Task

Selecting the correct footwear requires an honest assessment of your work environment and the hazards you face.

- If your primary focus is working directly with high-voltage equipment: Your safety depends on established procedures, but boots rated to the highest standard, like the CSA Omega, provide the best secondary defense.

- If your primary focus is general work with incidental risk of electrical contact: Standard ASTM F2413 (EH) rated boots offer a crucial layer of protection against accidental contact in dry environments.

- If your primary focus is working in wet or constantly damp areas: You cannot rely on the EH rating for protection and must depend entirely on primary safety measures to prevent shock.

Ultimately, understanding both the capabilities and the critical limitations of your equipment is the foundation of true electrical safety.

Summary Table:

| Feature | Key Detail |

|---|---|

| Primary Function | Acts as an insulator to prevent the body from completing an electrical circuit to the ground. |

| Core Principle | Uses non-conductive soles/heels (e.g., rubber) to provide high electrical resistance. |

| Common Standards | ASTM F2413 (EH): Protects against up to 600V (dry conditions). CSA (Omega): Protects against up to 18,000V. |

| Critical Limitation | Protection is a secondary measure and is compromised by moisture, damage, or contamination. |

Ensure your team is equipped with the right protective footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM and CSA-certified EH safety boots for distributors, brand owners, and bulk clients. Our production capabilities ensure durability and compliance for maximum on-site safety.

Contact 3515 today for reliable, high-volume footwear solutions tailored to your electrical safety needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How do professional slip-resistant safety shoes protect older workers? Stability Solutions for the Aging Workforce

- How does the sole structure of professional safety shoes prevent plantar fascia degeneration? Protect Your Foot Health

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- When did the development of safety footwear begin and what drove its introduction? The Industrial Revolution's Impact on Worker Safety

- How do professional safety shoes protect the musculoskeletal system? Enhance Worker Ergonomics & Reduce Fatigue

- How do composite safety shoes react to impact compared to steel toed shoes? A Guide to Choosing the Right Protection

- How does BIA assist in evaluating physical readiness? Optimize Performance for Personnel in Heavy Safety Shoes

- What are the key properties of nylon as an upper material for labour protection shoes? A Guide to Lightweight Durability