In the 1970s, the brand's fabric technology evolved significantly by introducing softer, more versatile materials designed for a new market. This shift was marked by the launch of 1000d and 500d Plus fabrics, which retained the brand's signature durability while adding the softness necessary to expand from industrial workwear into consumer urbanwear.

The core evolution during the 1970s was not about creating a tougher fabric, but about strategically engineering a softer one. This allowed the brand to apply its established reputation for durability to a wider range of products that required more comfort and flexibility.

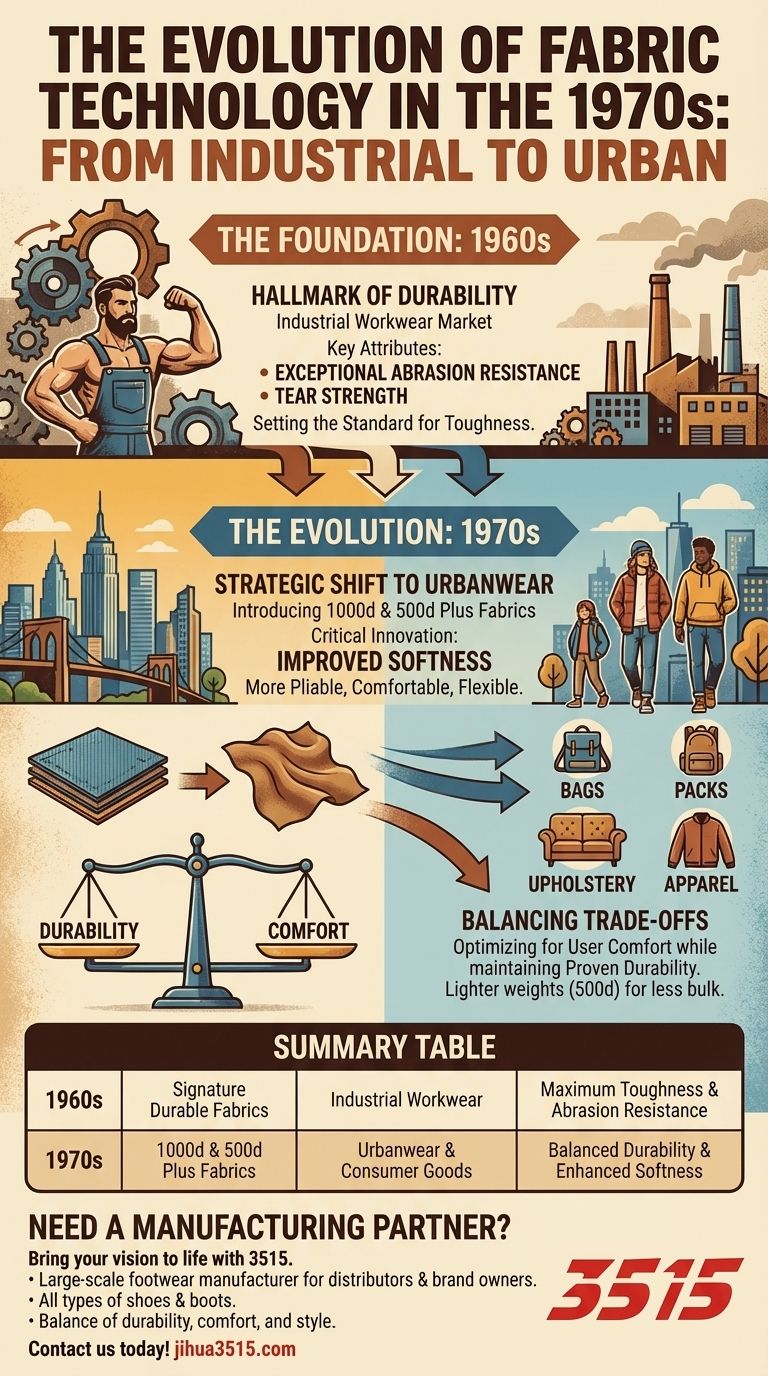

The Foundation: A Legacy Forged in the 1960s

The Hallmark of Durability

The brand first established its identity in the 1960s with the introduction of its signature durable performance fabrics.

These initial materials were defined by their exceptional abrasion resistance and tear strength, setting a new standard for toughness in textiles.

The Initial Market: Industrial Workwear

This high level of performance quickly caught the attention of workwear designers. The fabrics became a go-to choice for applications where durability was the most critical factor, cementing the brand's reputation for ruggedness.

The 1970s Evolution: From Industrial Strength to Urban Versatility

A Strategic Shift to Urbanwear

The 1970s marked a deliberate expansion for the brand. It targeted the growing urbanwear market, which demanded a different set of fabric characteristics than industrial workwear.

Introducing 1000d and 500d Plus

To meet this new demand, the brand introduced two key innovations: 1000d and 500d Plus fabrics. These new materials represented a significant evolution of their core technology.

The Critical Innovation: Improved Softness

The most important advancement of these new fabrics was their improved softness. While the original materials were exceptionally tough, they were often too rigid for everyday consumer products.

This enhanced softness made the fabrics more pliable and comfortable to the touch.

Unlocking New Applications

This single improvement in feel and flexibility allowed the brand to enter completely new product categories. The 1000d and 500d Plus fabrics were ideal for bags, packs, upholstery, lighter-weight gear, and apparel.

Understanding the Trade-offs

Balancing Durability with Comfort

The move toward softer fabrics represents a classic engineering trade-off. The primary goal was no longer just maximizing tear strength but optimizing for a balance between proven durability and necessary user comfort.

The Role of Fabric Weight

The designations 1000d and 500d likely refer to the fabric's denier—a measure of fiber thickness and weight. By developing lighter-weight options like 500d, the brand could create products that were less bulky and more suitable for daily use without sacrificing their reputation for being tough.

How This Applies to Your Strategy

This historical evolution provides a clear blueprint for adapting a core technology to new markets.

- If your primary focus is brand strategy: The 1970s shows how modifying a single attribute (softness) of a core technology can unlock adjacent markets and dramatically expand a brand's reach.

- If your primary focus is product development: This history proves that technical performance must always be balanced with user experience; a product is only successful if it fits the practical and physical demands of its intended user.

Ultimately, this evolution demonstrates that true innovation is often about thoughtful adaptation, not just raw invention.

Summary Table:

| Era | Key Fabric Innovation | Primary Market | Core Attribute |

|---|---|---|---|

| 1960s | Signature Durable Fabrics | Industrial Workwear | Maximum Toughness & Abrasion Resistance |

| 1970s | 1000d & 500d Plus Fabrics | Urbanwear & Consumer Goods | Balanced Durability & Enhanced Softness |

Need a Manufacturing Partner for Your Next Product Line?

Just as the brand adapted its core technology for new markets, 3515 can help you bring your vision to life. As a large-scale manufacturer, we produce a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring the perfect balance of durability, comfort, and style for your target audience.

Contact us today to discuss your manufacturing needs and see how we can add value to your brand.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today