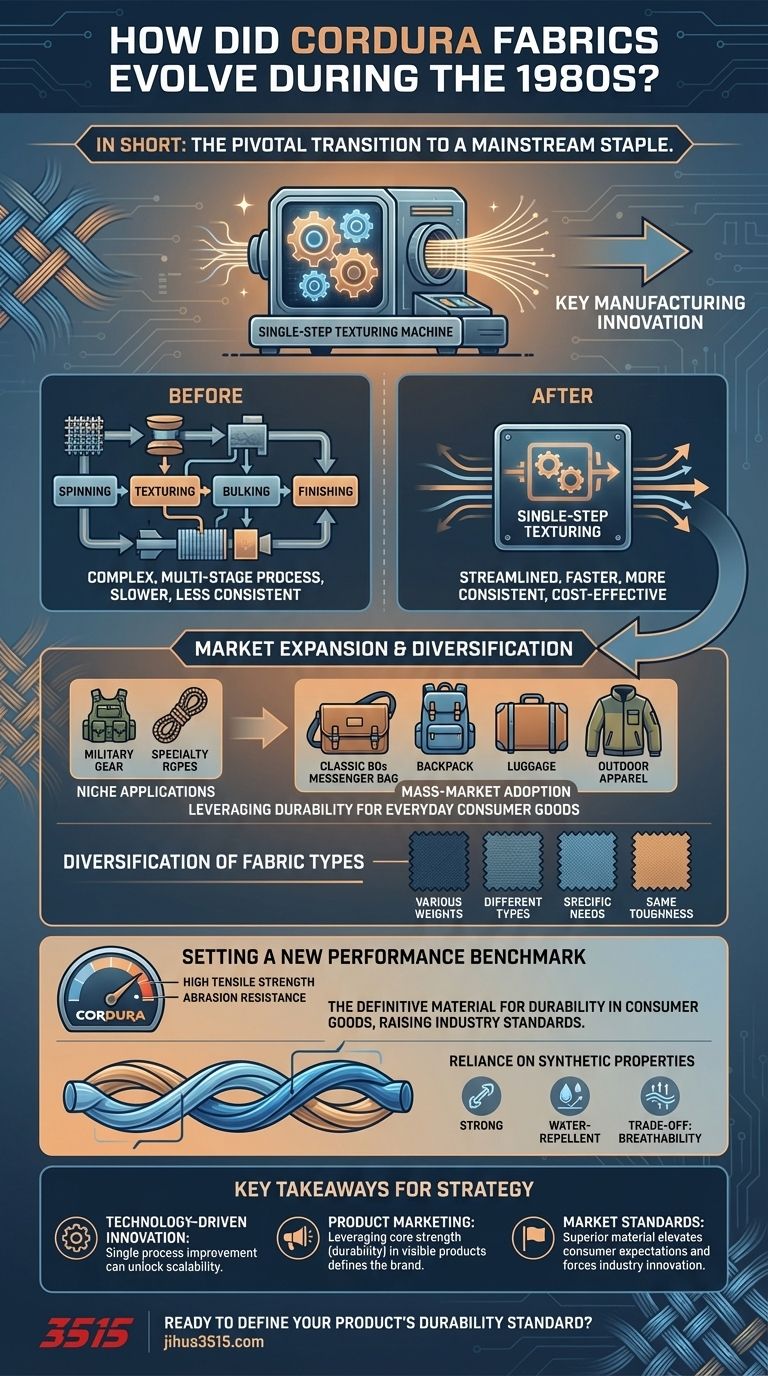

In short, the 1980s marked Cordura's pivotal transition from a specialty material into a mainstream staple. This evolution was driven by a key manufacturing innovation—the single-step texturing machine—which enabled the creation of new fabric types and fueled its widespread adoption in everyday consumer goods like luggage and messenger bags.

The core takeaway is that technological advancement was the catalyst for market expansion. By making the production of high-performance nylon yarns more efficient, Cordura could move beyond niche applications and become the definitive material for durability in the consumer goods industry.

The Technological Leap: From Niche to Mainstream

The story of Cordura's rise in the 1980s is fundamentally about a manufacturing breakthrough that unlocked its commercial potential. Before this period, producing such durable textiles was a more complex process.

The Single-Step Texturing Breakthrough

The most significant development was the establishment of the first single-step texturing machine for nylon yarns. This innovation streamlined what was previously a multi-stage process.

Texturing is what gives the flat, smooth nylon filaments a bulkier, more natural, and abrasion-resistant finish, similar to canvas but far stronger.

Implications for Production

By consolidating this process into a single step, production became faster, more consistent, and more cost-effective. This efficiency was crucial for scaling up and making Cordura fabric accessible for mass-market products.

Expanding the Market: Beyond Specialty Use

With production streamlined, Cordura was positioned to enter new markets. The 1980s saw a deliberate expansion into consumer goods, leveraging its reputation for extreme durability.

The Rise of the Messenger Bag

Cordura became famously associated with messenger bags and backpacks during this decade. These products required a material that could withstand daily abuse, abrasion, and weather, and Cordura's properties were a perfect match.

Diversification and New Fabric Types

The new manufacturing capabilities also allowed for the introduction of different fabric weights and types. This diversification meant that designers of luggage, bags, and outdoor apparel could choose a Cordura variant perfectly suited to their specific needs without compromising on the brand's core promise of toughness.

Understanding the Trade-offs

The success of Cordura also set a new standard, which came with its own set of implications for the industry.

The New Performance Benchmark

Cordura's high tensile strength and resistance to abrasion became the benchmark for durable goods. Any competitor in the luggage or outdoor gear space had to measure their materials against it, effectively raising the quality standard for the entire market.

Reliance on Synthetic Properties

As a nylon-based fabric, Cordura is exceptionally strong and water-repellent. However, this also cemented the industry's reliance on synthetic fibers for performance applications, often prioritizing durability and weather resistance over qualities like the breathability found in natural fibers.

How This Informs Material Strategy

Understanding Cordura's history provides a clear model for how materials achieve market dominance.

- If your primary focus is on technology-driven innovation: Recognize that a single manufacturing process improvement can be the key to unlocking mass-market adoption and scalability.

- If your primary focus is on product marketing: See how leveraging a material's core strength (durability) in a highly visible product category (messenger bags) can define its brand for decades.

- If your primary focus is on market standards: Acknowledge that introducing a superior material can elevate consumer expectations and force an entire industry to innovate.

Ultimately, the 1980s defined Cordura by proving that technical performance and everyday utility could be one and the same.

Summary Table:

| Key Development | Impact on Cordura Fabric |

|---|---|

| Single-Step Texturing Machine | Streamlined production, making it faster, more consistent, and cost-effective. |

| Market Expansion | Moved beyond specialty uses into consumer goods like messenger bags and luggage. |

| Fabric Diversification | Enabled creation of various fabric weights, broadening application possibilities. |

| New Performance Benchmark | Set a new industry standard for durability in textiles. |

Ready to Define Your Product's Durability Standard?

Just as manufacturing innovation defined Cordura in the 1980s, the right production partner can define your brand's success today. 3515, a large-scale manufacturer, produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots, ensuring quality and scalability for your market.

Let's build the next standard together. Contact our team now for a consultation.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

People Also Ask

- What is special about shell cordovan leather? Unmatched Durability & Unique Aging

- Why should you try on shoes with the socks you plan to wear regularly? Ensure a Perfect, Pain-Free Fit

- How can plantar warts develop, and why is indoor footwear recommended? Protect Your Feet from Pain and Infection

- What are the technical advantages of 1D-CNN for motion sensor signals? Elevate Accuracy in Gait Analysis

- What specific brands or types of boots were mentioned? Find Your Perfect Fit for Support & Safety

- What parts of the shoe are assessed using a sandpaper tip tool? Uncover the 3 Key Durability Test Zones

- How important is shoe fit for all-day wear? The Foundation of Endurance and Injury Prevention

- How does the durability of sustainable shoes benefit the environment? Break the Cycle of Fast Fashion