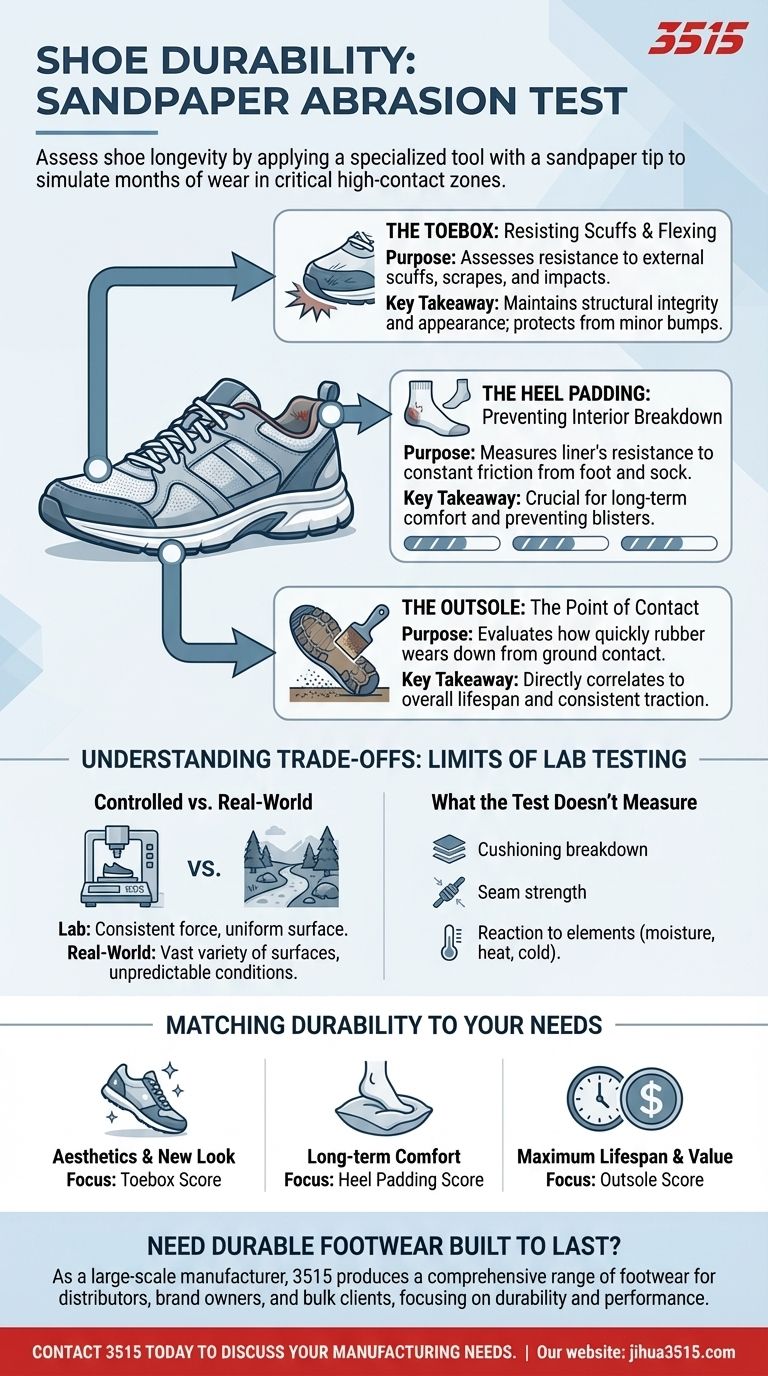

To assess a shoe's durability, a specialized tool with a sandpaper tip is applied to three critical areas: the toebox, the heel padding, and the outsole. This targeted abrasion test is designed to simulate months or even years of wear and tear in a controlled, measurable way.

This test isn't about random damage; it's a precise method to forecast how a shoe will withstand the consistent friction and stress it will face in high-contact zones during its lifespan.

Why These Specific Parts Matter

The selection of the toebox, heel padding, and outsole for durability testing is not arbitrary. Each location represents a primary point of failure or significant wear that directly impacts the shoe's performance, comfort, and longevity.

The Toebox: Resisting Scuffs and Flexing

The toebox is the forward-most part of the shoe, constantly facing external scuffs, scrapes, and impacts.

Testing this area reveals how well the upper material can maintain its structural integrity and appearance. A durable toebox means the shoe will look better for longer and protect the foot from minor bumps.

The Heel Padding: Preventing Interior Breakdown

The heel padding and collar area are in constant contact with your foot and sock. This zone endures significant friction every time you take a step and when you put the shoe on or take it off.

Applying the abrasion tool here assesses the liner material's resistance to pilling, tearing, and wearing thin. High durability in this area is crucial for long-term comfort and preventing blisters.

The Outsole: The Point of Contact

The outsole is the most obvious area for a durability test, as it's the only part of the shoe that is in constant contact with the ground.

Testing the outsole material with an abrasion tool measures how quickly the rubber will wear down. This directly correlates to the shoe's overall lifespan and its ability to provide consistent traction over time.

Understanding the Trade-offs: The Limits of Lab-Based Testing

While standardized lab tests provide invaluable comparative data, it's important to understand their limitations. They represent a controlled simulation, not the chaos of the real world.

Controlled vs. Real-World Conditions

A lab test uses a consistent force and a uniform abrasive surface. It cannot account for the vast variety of surfaces you encounter, from wet pavement and rough trails to sharp rocks and uneven terrain.

What the Test Doesn't Measure

This specific test focuses solely on abrasion resistance. It doesn't measure other critical factors like the breakdown of cushioning foam over time, the strength of stitched seams under stress, or how materials react to moisture, heat, or cold.

Matching Durability to Your Needs

Understanding what these durability scores mean allows you to choose a shoe that aligns with your specific priorities.

- If your primary focus is aesthetics and keeping shoes looking new: Pay close attention to the toebox durability score.

- If your primary focus is long-term comfort and avoiding interior wear: A high score on heel padding durability is a key indicator.

- If your primary focus is maximum lifespan and value: The outsole durability score is the most critical metric for you.

Ultimately, this data empowers you to look beyond marketing and select a shoe based on objective proof of its construction quality.

Summary Table:

| Shoe Part Tested | Purpose of the Abrasion Test | Key Takeaway |

|---|---|---|

| Toebox | Assesses resistance to scuffs, scrapes, and impacts on the upper material. | Determines how well the shoe maintains its appearance and protects the foot. |

| Heel Padding | Measures the liner's resistance to friction from the foot and sock. | Crucial for long-term comfort and preventing blisters from interior wear. |

| Outsole | Evaluates how quickly the rubber wears down from ground contact. | Directly correlates to the shoe's overall lifespan and traction. |

Need durable footwear built to last? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, designed with a focus on the durability and performance you've just read about. Let us help you deliver high-quality, long-lasting footwear to your customers.

Contact 3515 today to discuss your manufacturing needs.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How does the use of high-specification elastic fibers contribute to footwear market value? Scaling Success with Fit

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- What are the functional features of traditional cowboy boots? Discover the Anatomy Built for the Saddle

- What are the advantages of using nitrile gloves for organophosphorus pesticides? Maximize Chemical Safety & Protection

- What are some common applications of open-cell and closed-cell foam in shoes? Optimize Comfort and Performance

- What are the advantages of foot-mounted Integrated IMUs? Unlock Precision Biomechanics for Footwear R&D

- What is the significance of extracting Center of Pressure (CoP) coordinate features? Enhancing Smart Shoe Classification

- Why are ISO standards and CE certifications critical for products? Ensure Safety & Sustainability in Your Supply Chain