Assessing the effectiveness of non-slip footwear is best done through a combination of tactile examination and active movement. To verify grip before purchasing, firmly press your hand against the sole to gauge the material's friction against your skin, then perform a walk test on a smooth, slick surface like a tiled floor to feel how the shoe responds to motion.

True slip resistance is determined by the interaction between the sole material and the floor surface. A physical test allows you to verify that the rubber compound provides the necessary friction coefficient rather than relying solely on the manufacturer's label.

Evaluating the Sole Mechanics

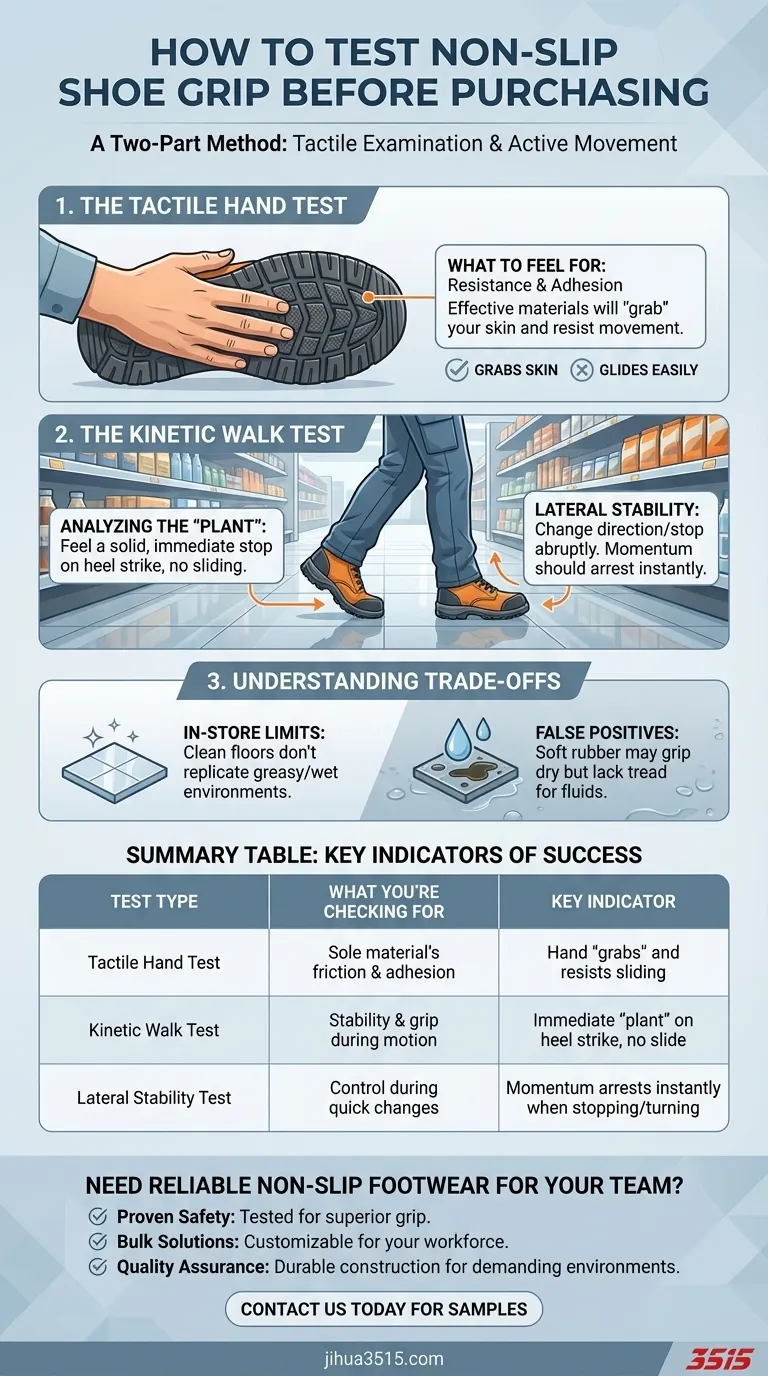

The Tactile Hand Test

The first step in verification involves a direct tactile assessment. Place your palm flat against the outsole of the shoe and apply moderate pressure.

What to Feel For

You are testing for resistance and adhesion. As you try to slide your hand across the sole, effective non-slip materials will "grab" your skin and resist the movement. If your hand glides easily over hard plastic or smooth rubber, the shoe is likely to fail in slippery conditions.

Simulating Real-World Usage

The Kinetic Walk Test

Static friction (standing still) is different from kinetic friction (moving). Put the shoes on and locate a smooth, non-carpeted area of the store, such as a polished tile or linoleum aisle.

Analyzing the "Plant"

Walk at a normal to brisk pace, focusing on the moment your heel strikes the ground. You should feel a solid, immediate plant without any sensation of sliding or "hydroplaning."

Testing Lateral Stability

Change directions quickly or stop abruptly during your walk. High-quality non-slip shoes should arrest your momentum instantly, giving you confidence in your stability.

Understanding the Trade-offs

The "Clean Floor" Variable

It is critical to recognize the limitations of an in-store test. A clean tiled floor does not perfectly replicate the hazards of a greasy commercial kitchen or a wet industrial environment.

False Positives

Some softer rubber compounds may grip well on dry store floors but lack the tread pattern necessary to channel fluids away. While the tests described here confirm the rubber quality, they cannot fully guarantee performance against heavy oil or standing water.

Making the Right Choice for Your Safety

These manual tests serve as a vital filter to eliminate footwear with inferior rubber compounds or ineffective tread designs.

- If your primary focus is maximum traction: Prioritize the hand test to ensure the rubber feels soft and offers high resistance against your skin.

- If your primary focus is stability on mixed surfaces: Prioritize the walk test on the slickest available flooring to ensure the shoe supports sudden stops and turns.

Your safety depends on the physical reality of friction, so trust your tactile experience over the marketing claims on the box.

Summary Table:

| Test Type | What You're Checking For | Key Indicator of Success |

|---|---|---|

| Tactile Hand Test | Sole material's friction and adhesion | Your hand 'grabs' and resists sliding across the sole |

| Kinetic Walk Test | Stability and grip during motion | Immediate 'plant' on heel strike with no sliding sensation |

| Lateral Stability Test | Control during quick direction changes | Momentum arrests instantly when stopping or turning |

Need Reliable Non-Slip Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-traction footwear for distributors, brand owners, and bulk clients. Our expertise ensures every pair is engineered with advanced rubber compounds and tread patterns designed for real-world hazards.

We provide:

- Proven Safety: Footwear tested for superior grip on slippery surfaces.

- Bulk Solutions: Customizable options to meet the specific needs of your workforce.

- Quality Assurance: Durable construction built to withstand demanding environments.

Protect your team with footwear you can trust. Contact us today to discuss your requirements and request samples!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- Why are industrial-grade safety shoes mandatory in metallurgical workshops? Essential Protection for Extreme Environments

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today