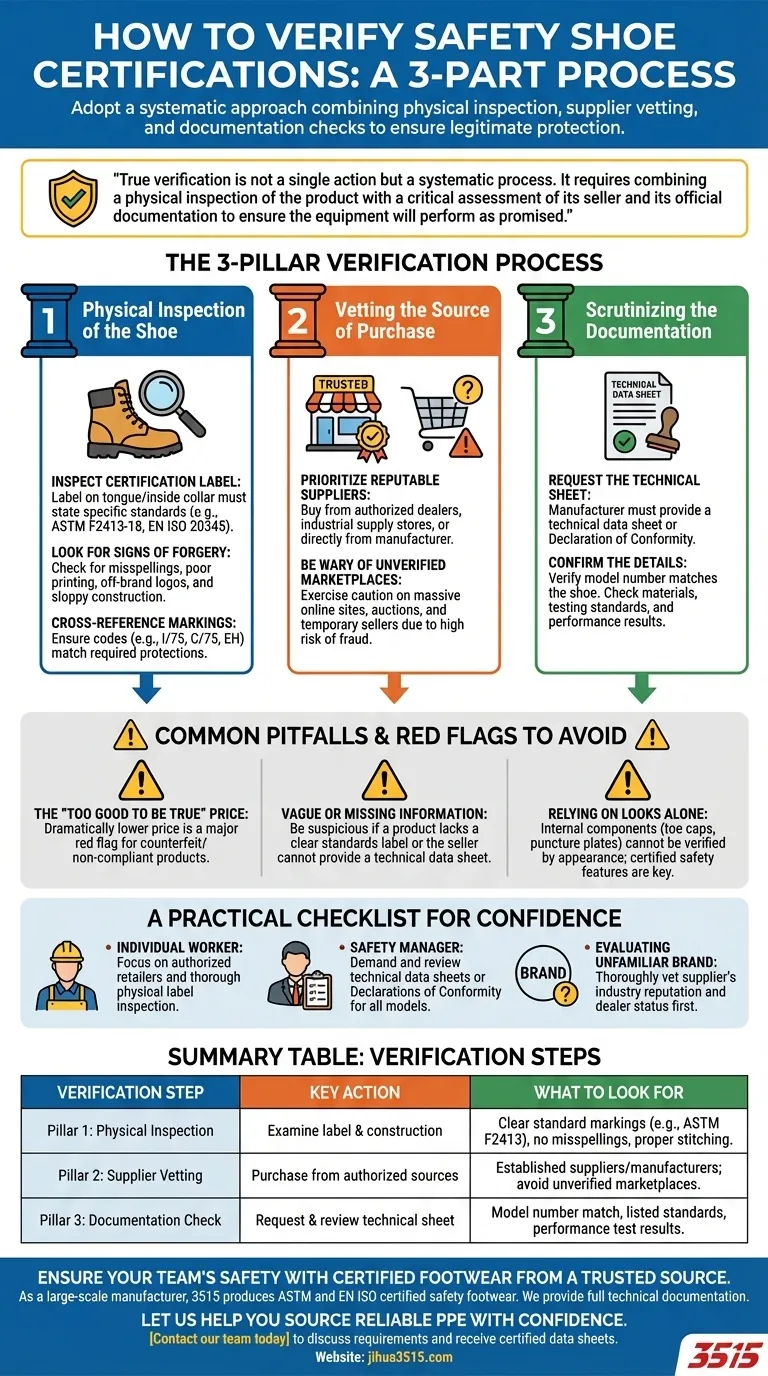

To verify the legitimacy of safety shoe certifications, you must adopt a three-part process. This involves physically inspecting the shoe's labeling for specific standard markings, purchasing only from reputable and established suppliers, and cross-referencing the product with the manufacturer's official technical data sheets to confirm its protective features and compliance.

True verification is not a single action but a systematic process. It requires combining a physical inspection of the product with a critical assessment of its seller and its official documentation to ensure the equipment will perform as promised.

A Three-Pillar Verification Process

A reliable safety shoe is a critical piece of Personal Protective Equipment (PPE). Ensuring its certification is genuine requires more than a quick glance. The following three pillars provide a comprehensive framework for confirming authenticity and protecting yourself from counterfeit or non-compliant products.

Pillar 1: Physical Inspection of the Shoe

Inspect the Certification Label Legitimate safety footwear has a permanent label, typically stitched to the tongue or inside collar. This label must clearly state the specific safety standard it meets, such as ASTM F2413-18 (the U.S. standard) or EN ISO 20345 (the European standard).

Look for Signs of Forgery Examine the label and the shoe for red flags. Counterfeit products often have labels with misspellings, low-quality printing, or logos that appear slightly off-brand. Poor overall construction, like sloppy stitching or weak glue, is another immediate warning sign.

Cross-Reference the Markings The label will contain a line of codes indicating its specific protections (e.g., I/75 for impact resistance, C/75 for compression resistance, EH for Electrical Hazard). Ensure these codes match the protections you require for your job.

Pillar 2: Vetting the Source of Purchase

Prioritize Reputable Suppliers The most effective way to avoid counterfeit gear is to purchase from an authorized dealer, a dedicated industrial supply store, or directly from the manufacturer. These channels have a vested interest in maintaining a legitimate supply chain.

Be Wary of Unverified Marketplaces Exercise extreme caution when buying from third-party sellers on massive online marketplaces, auction sites, or from temporary sellers. The risk of encountering fraudulent or non-compliant products in these environments is significantly higher.

Pillar 3: Scrutinizing the Documentation

Request the Technical Sheet A manufacturer of certified safety footwear will always have a technical data sheet or a Declaration of Conformity for their products. This document is the ultimate proof of compliance. Reputable suppliers should be able to provide this upon request.

Confirm the Details The technical sheet lists the specific model number, materials used, and the exact standards it was tested against. Verify that the model number on the sheet matches the model number of the shoe you are inspecting. It will also detail the performance results from testing, confirming its protective capabilities.

Common Pitfalls and Red Flags to Avoid

Trusting your safety to a product requires vigilance. Counterfeiters often exploit common assumptions. Being aware of these pitfalls is a critical layer of your personal safety strategy.

The "Too Good to Be True" Price

Certified safety components and robust materials have a baseline cost. If a pair of safety shoes is being sold at a price dramatically lower than the market average, it is a significant red flag that it may be counterfeit or non-compliant.

Vague or Missing Information

Legitimate manufacturers are proud of their safety ratings and provide clear, accessible information. Be suspicious of any product that lacks a clear standards label or any seller who is unwilling or unable to provide a technical data sheet.

Relying on Looks Alone

A shoe can be designed to look like a heavy-duty safety boot without containing any of the certified protective components. A steel or composite toe, puncture-resistant plate, and other features are internal and cannot be verified by appearance alone.

A Practical Checklist for Confidence

Your approach to verification may change slightly depending on your role. Use these guidelines to ensure you are making the right choice for your specific situation.

- If you are an individual worker: Your primary focus should be purchasing from an authorized, well-known retailer and performing a thorough physical inspection of the shoe's certification label before use.

- If you are a safety manager outfitting a team: You must demand and review the technical data sheets or Declarations of Conformity for every footwear model you purchase to maintain compliance and ensure worker safety.

- If you are evaluating an unfamiliar brand: Begin by thoroughly vetting the supplier's industry reputation and confirming their status as an authorized dealer before spending any time on product inspection.

Ultimately, taking ownership of this verification process is the most reliable way to ensure your protective equipment will function when you need it most.

Summary Table:

| Verification Step | Key Action | What to Look For |

|---|---|---|

| Pillar 1: Physical Inspection | Examine the shoe's label and construction. | Clear standard markings (e.g., ASTM F2413), no misspellings, proper stitching. |

| Pillar 2: Supplier Vetting | Purchase from authorized, reputable sources. | Established industrial suppliers or direct from manufacturers; avoid unverified marketplaces. |

| Pillar 3: Documentation Check | Request and review the technical data sheet. | Model number match, listed safety standards, and performance test results. |

Ensure your team's safety with certified footwear from a trusted source.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM and EN ISO certified safety footwear for distributors, brand owners, and bulk clients. We provide full technical documentation for every product, guaranteeing compliance and performance.

Let us help you source reliable PPE with confidence. Contact our team today to discuss your safety shoe requirements and receive certified product data sheets.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision