Maintaining the soles of your winter boots is about much more than just cleaning them when they get muddy. True maintenance is a proactive process of inspection, care, and timely repair that directly impacts your safety and the longevity of your investment. The core tasks involve regular cleaning to remove corrosive salt and debris, consistently inspecting the treads for wear, and seeking professional resoling once the grip becomes compromised.

The key to long-lasting winter boot soles isn't a single action, but a consistent cycle of care. Proactive cleaning prevents material degradation, while routine inspection tells you exactly when it's time for professional repair, ensuring you never compromise on safety or traction.

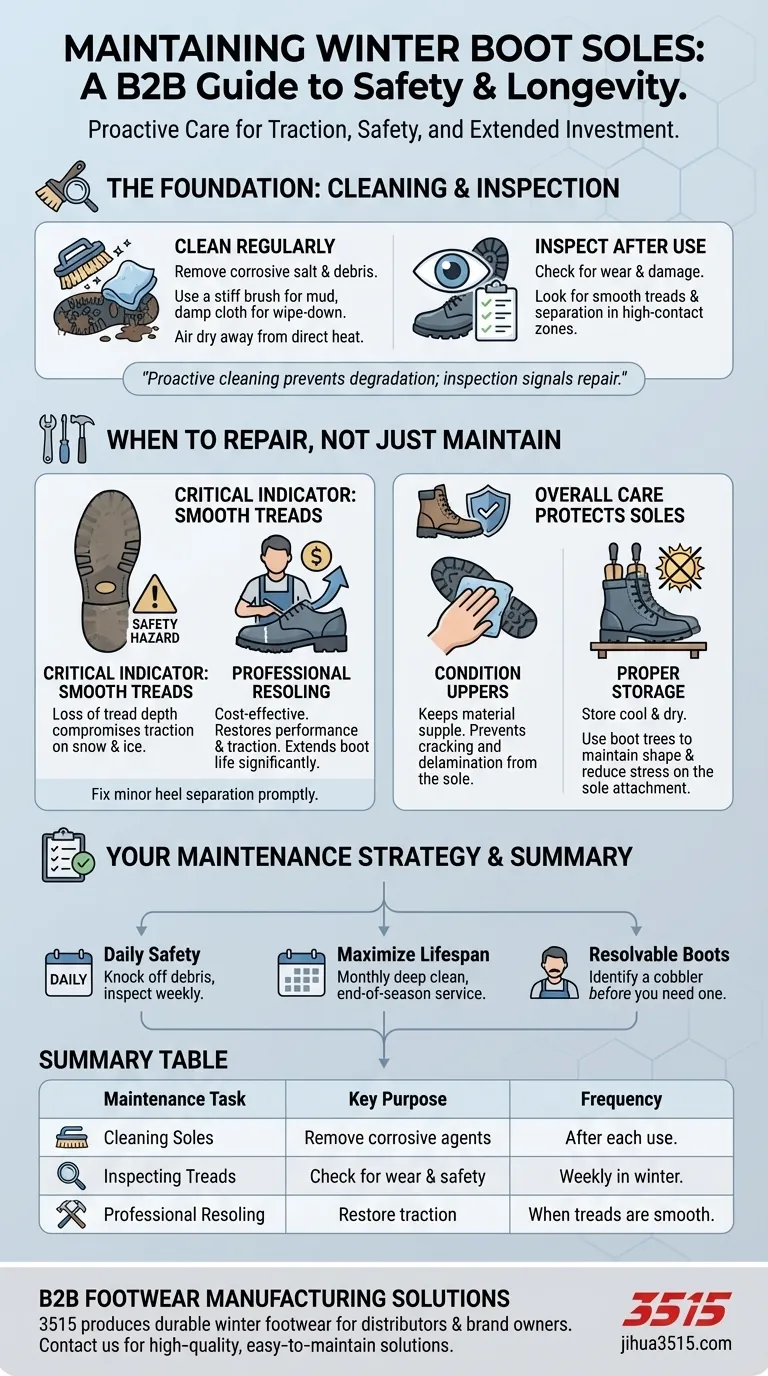

The Foundation of Sole Care: Cleaning and Inspection

Proper maintenance begins with simple, repeatable habits. How you clean and inspect your soles after use has the biggest impact on their lifespan.

Why Regular Cleaning is Non-Negotiable

Salts, chemicals, and mud don't just make boots look dirty; they actively degrade the rubber and synthetic compounds used in outsoles. Caked-on debris can also pack into the treads, rendering aggressive lug patterns ineffective and reducing your grip on slippery surfaces.

The Habit of Visual Inspection

After every cleaning, take a moment to look at the soles. Check for areas where the tread pattern is becoming smooth or worn down, especially in high-contact zones like the heel and ball of the foot. Also look for any signs of cracking or separation between the sole and the upper part of the boot.

The Correct Cleaning Technique

Use a stiff brush to remove dried mud and debris. For a more thorough cleaning, use a damp cloth to wipe down the entire sole and welt (the area where the sole joins the boot). Always allow boots to air dry naturally, away from direct heat sources like radiators, which can cause materials to crack.

Understanding When to Repair, Not Just Maintain

Maintenance can slow down wear, but it can't stop it entirely. Knowing the tipping point for professional repair is critical for both safety and extending the life of your boots.

The Critical Indicator: Smooth Treads

The most important sign that your soles need attention is a loss of tread depth. Once the lugs and patterns become smooth, the boot's ability to provide traction on snow and ice is severely compromised. This is no longer a maintenance issue; it's a safety hazard.

The Value of Professional Resoling

For high-quality boots, resoling is a highly cost-effective option. A professional cobbler can replace the worn-out outsole, restoring the boot's original traction and performance for a fraction of the cost of a new pair. This is the single best way to extend the life of your initial investment.

Addressing Minor Damage Promptly

Don't ignore small issues like a heel beginning to separate from the sole. Repairing minor damage immediately prevents water from getting in, which can lead to further deterioration of the boot's internal structure.

How Overall Boot Care Protects the Soles

The sole of your boot does not exist in isolation. The health of the entire boot, particularly the uppers and how you store it, directly impacts the sole's integrity and lifespan.

Conditioning the Uppers

For leather boots, regular conditioning keeps the material supple and strong. Dry, cracked leather can pull away from the sole, creating gaps that allow moisture to penetrate and cause the sole to delaminate.

The Critical Role of Proper Storage

At the end of the season, clean your boots thoroughly and store them in a cool, dry place away from direct sunlight. Stuffing them with newspaper or using boot trees helps maintain their shape, preventing creases and folds that can put stress on the area where the sole is attached.

A Maintenance Strategy for Your Boots

Your approach should match your goals for your footwear.

- If your primary focus is daily safety and performance: Make a habit of knocking off snow and debris after each use and visually inspecting the tread depth weekly.

- If your primary focus is maximizing the lifespan of your investment: Commit to a full clean and condition cycle monthly during the winter and a thorough end-of-season service before storing them.

- If you own high-quality, resolvable boots: Identify a reputable cobbler before you need one, so you're ready to act as soon as the treads show significant wear.

Proactive care ensures your boots are always ready to provide the stability and protection you depend on.

Summary Table:

| Maintenance Task | Key Purpose | Frequency |

|---|---|---|

| Cleaning Soles | Remove corrosive salt, debris, and prevent material degradation | After each use in harsh conditions |

| Inspecting Treads | Check for wear, smooth spots, and ensure traction for safety | Weekly during winter season |

| Professional Resoling | Restore lost traction and extend boot life significantly | When treads become smooth or worn |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of winter boots designed for longevity and performance. Let us help you provide your customers with high-quality, easy-to-maintain footwear. Contact our team today to discuss your manufacturing needs and how we can bring value to your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture