To significantly extend the lifespan of your PVC work boots, you must focus on a consistent routine of proper cleaning, strategic storage, and dedicated use. Rinsing them after exposure to chemicals or dirt, and storing them away from direct sunlight and heat are the most critical actions you can take to prevent the material from degrading.

PVC boots are valued for their resistance to water and chemicals, but they are not indestructible. Their longevity hinges on preventing the degradation of the synthetic material itself, which is primarily caused by chemical exposure, UV radiation, and physical abrasion.

Why PVC Boots Fail: Understanding the Material

To properly care for your boots, you first need to understand their vulnerabilities. Unlike leather, which is an organic material, PVC (Polyvinyl Chloride) is a synthetic polymer whose integrity can be compromised in specific ways.

Chemical Attack and Material Breakdown

PVC's excellent chemical resistance is one of its main advantages, but prolonged or intense exposure can still cause damage. Harsh substances can slowly leach the plasticizers that keep the material flexible, leading to stiffness and eventual cracking.

The Impact of UV Radiation

Constant exposure to direct sunlight is a primary enemy of PVC. The UV radiation in sunlight breaks down the polymer chains in the material, causing it to become brittle, discolored, and highly susceptible to cracking under stress.

Physical Stress and Contaminants

While PVC is tough, it is not immune to physical wear. Abrasive materials like gravel, mud, and caked-on dirt can wear down the sole's tread and stress the seams, compromising the boot's structural integrity and waterproof seal.

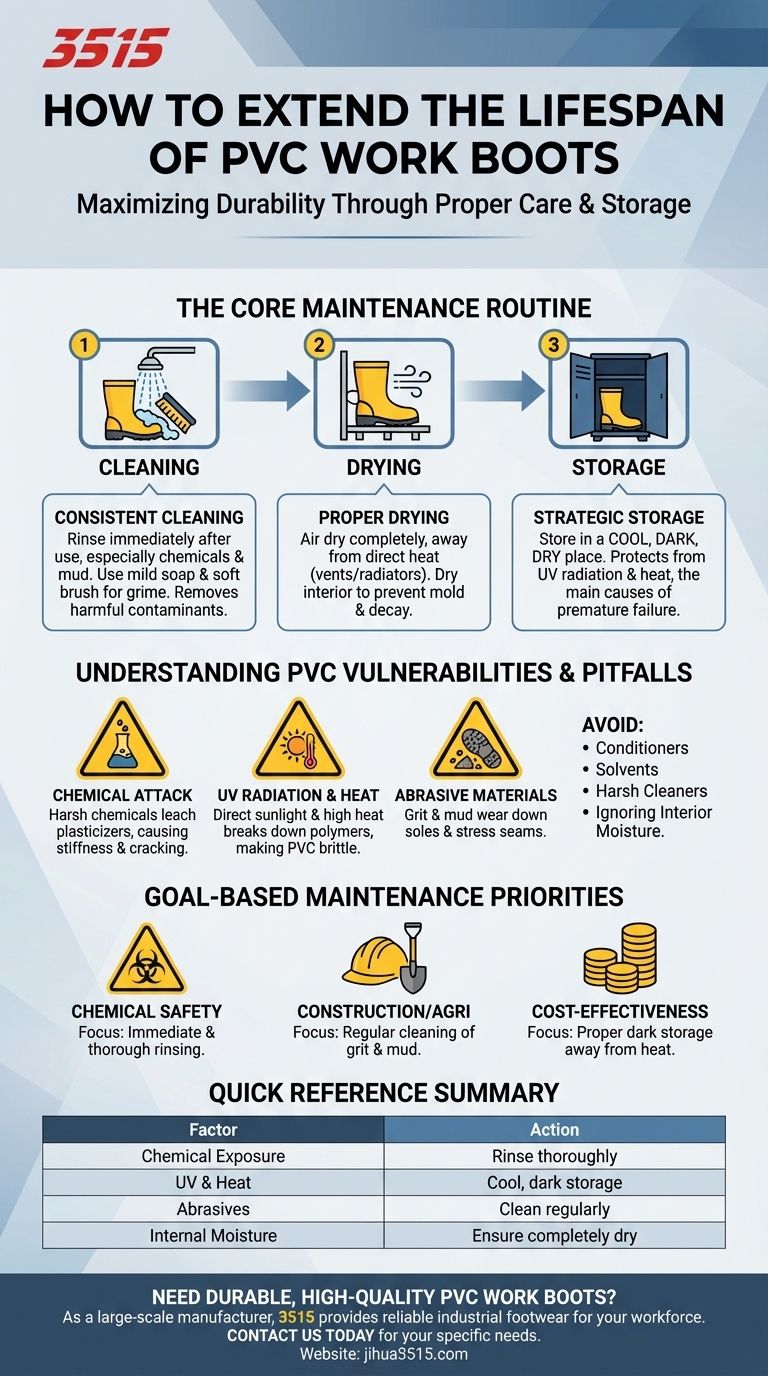

The Core Maintenance Routine

A simple, consistent care routine is far more effective than occasional intensive cleaning. These three steps are the foundation of long-term boot preservation.

Step 1: Consistent Cleaning

Immediately after use, especially after exposure to chemicals, mud, or concrete, rinse your boots thoroughly with plain water. For more stubborn grime, use a soft brush and mild soap. This removes contaminants before they can damage the material.

Step 2: Proper Drying

Always allow your boots to air dry completely after cleaning or use. Crucially, keep them away from direct heat sources like vents or radiators, as high heat can warp the PVC and accelerate material degradation. Drying the interior is just as important to prevent mold and liner decay.

Step 3: Strategic Storage

Store your boots in a cool, dark, and dry place. A garage locker, mudroom closet, or basement shelf is ideal. This single habit protects the PVC from the damaging effects of UV radiation and heat, which is the most common cause of premature failure.

Understanding the Pitfalls and Misconceptions

Applying care techniques from other materials, like leather, can be ineffective or even damaging to PVC.

The Myth of "Conditioning"

PVC is a non-porous plastic; it does not "dry out" and absorb traditional leather conditioners. These products will simply sit on the surface and attract dirt. While some specialized rubber or vinyl protectants can offer a degree of UV protection, they are not a substitute for proper storage.

The Danger of Solvents and Harsh Cleaners

Never use solvents, oils, or aggressive chemical cleaners on your PVC boots unless they are specifically designed for that purpose. These substances can strip plasticizers from the material, making it brittle and destroying its protective qualities.

Ignoring the Inside of the Boot

Moisture trapped inside the boot not only leads to odor and bacteria but can also cause the boot's inner lining to degrade and detach over time. Ensure the inside is fully dry before storage, using newspaper or a boot dryer if necessary.

Making the Right Choice for Your Goal

Your specific work environment should guide your maintenance priorities.

- If your primary focus is safety in chemical environments: Your most critical action is immediate and thorough rinsing after any potential exposure.

- If your primary focus is work in construction or agriculture: Regular cleaning to remove abrasive grit and mud is essential to preserve the soles and seams.

- If your primary focus is maximizing cost-effectiveness: Proper storage away from sunlight and heat will provide the greatest increase in lifespan for the least amount of daily effort.

By treating your PVC boots with this preventative care, you ensure they maintain their protective qualities and serve you effectively for their maximum possible lifespan.

Summary Table:

| Key Factor | Impact on PVC Boots | Preventative Action |

|---|---|---|

| Chemical Exposure | Leaches plasticizers, causing stiffness & cracking | Rinse thoroughly with water after exposure |

| UV Radiation & Heat | Breaks down polymer chains, causing brittleness | Store in a cool, dark, dry place away from sunlight |

| Abrasive Materials | Wears down soles and stresses seams | Clean regularly with a soft brush and mild soap |

| Internal Moisture | Degrades inner lining and causes odor | Ensure boots are completely dry inside before storage |

Need durable, high-quality PVC work boots that are built to last? As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure your workforce gets reliable, long-lasting protection. Contact us today to discuss your specific needs and discover how we can provide the right footwear solution for your business.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What role do Western work boots play in popular culture? From Cowboy Utility to Fashion Icon

- How does the height of PVC work boots affect protection? A Guide to Choosing the Right Boot for Your Job

- What are the main disadvantages of cowboy boots? From Saddle to Sidewalk Limitations

- What should be considered for comfort and fit in farming and gardening boots? Ensure Long-Term Endurance

- What are the practical reasons for the popularity of cowboy boots as work attire? Unmatched Durability & Protection

- Why are flexible-soled boots recommended for winter skiing? Uncover the Warmth vs. Performance Trade-Off

- How do quality boots reduce worker fatigue? Boost Productivity and Safety

- What is the importance of the flex point in boot fitting? The Key to Ultimate Comfort and Stability