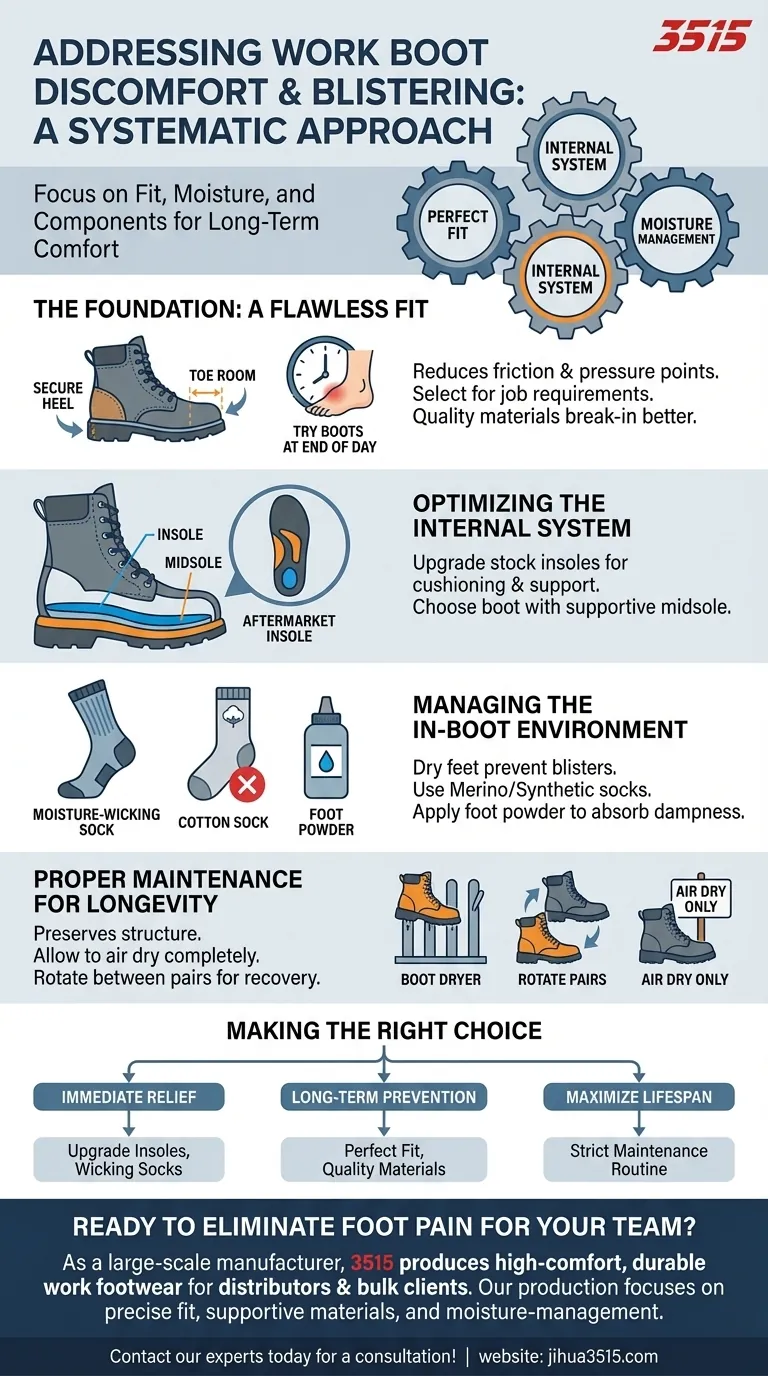

To address discomfort and blistering in work boots, you must focus on three key areas: achieving a perfect fit, managing moisture inside the boot, and upgrading critical internal components like the insole. These elements work together to reduce friction and provide the necessary support for long hours on your feet.

The core issue is rarely a single "bad boot" but rather a breakdown in the system connecting your foot, your sock, and your boot. Lasting comfort comes from optimizing this entire system, not just fixing one part.

The Foundation: A Flawless Fit

The most common cause of foot pain and blisters is an incorrect boot fit. A boot that is too loose allows your foot to slide, creating friction, while a boot that is too tight creates pressure points.

Why Fit is Non-Negotiable

A proper fit secures your heel while giving your toes enough room to move naturally. This stability is the first line of defense against the friction that causes blisters and the pressure that leads to general discomfort.

Selecting for Your Work Environment

The ideal boot is designed for your specific job requirements. It's crucial to try boots on in-store, preferably at the end of the day when your feet are slightly swollen, to find a style that provides the right support and protection for your environment.

The Role of High-Quality Materials

Boots made from premium, durable materials not only last longer but also conform better to the shape of your foot over time. This break-in process is essential for achieving personalized comfort.

Optimizing the Boot's Internal System

Even with a perfect fit, the factory components inside a work boot may not be sufficient for your needs. Strategic upgrades can dramatically enhance comfort and support.

The Immediate Impact of Insoles

Stock insoles are often a weak point. Upgrading to a high-quality aftermarket insole is one of the fastest and most effective ways to add cushioning, improve arch support, and reduce foot fatigue.

Understanding the Midsole's Function

The midsole is the layer between the insole and the outsole, responsible for shock absorption and stability. While you cannot change it, choosing a boot with a supportive midsole material from the start is critical for long-term comfort.

Managing the In-Boot Environment

A dry foot is a comfortable foot. Moisture from sweat softens the skin, making it highly susceptible to the friction that causes blisters.

The Critical Role of Moisture-Wicking Socks

Never wear cotton socks with work boots. Instead, choose socks made from moisture-wicking materials like merino wool or specific synthetics that pull sweat away from your skin, keeping your feet significantly drier.

Using Foot Powder for Added Dryness

Applying foot powder before putting on your boots is a simple step that helps absorb excess moisture throughout the day. This reduces the dampness that contributes to both blisters and odor.

The Pitfalls of Ignoring Proper Maintenance

How you care for your boots between shifts directly impacts their comfort and lifespan. Neglecting maintenance allows problems to develop.

Preventing Material Breakdown

Boots that are not dried properly after a wet shift will lose their shape and supportive structure. Always allow them to air dry completely away from direct heat.

The Benefit of Boot Rotation

If possible, rotate between two pairs of work boots. This gives each pair a full day to dry out and allows the cushioning materials in the midsole to decompress and recover their supportive qualities.

Why a Boot Dryer is a Smart Investment

A boot dryer is an excellent tool for safely and thoroughly drying your boots overnight. It prevents the moisture buildup that leads to material degradation, odor, and an environment ripe for blisters.

Making the Right Choice for Your Goal

Your strategy should depend on whether you need immediate relief or are planning for long-term prevention.

- If your primary focus is immediate relief from pain: Start by upgrading your insoles and switching to high-quality, moisture-wicking socks.

- If your primary focus is long-term prevention: Prioritize selecting a perfectly fitted boot made of quality materials that is appropriate for your job.

- If your primary focus is maximizing boot lifespan and comfort: Implement a strict maintenance routine of cleaning, drying, and rotating your boots.

By taking control of fit, moisture, and maintenance, you can transform your work boots from a source of pain into a reliable foundation for a productive day.

Summary Table:

| Key Focus Area | Key Action | Primary Benefit |

|---|---|---|

| Perfect Fit | Try boots on in-store, ensure heel security and toe room. | Reduces friction and pressure points. |

| Internal System | Upgrade to high-quality aftermarket insoles. | Improves cushioning, arch support, and reduces fatigue. |

| Moisture Control | Wear moisture-wicking socks (e.g., merino wool) and use foot powder. | Keeps feet dry, preventing blister-causing friction. |

| Proper Maintenance | Air dry boots completely, rotate pairs, use a boot dryer. | Preserves boot structure, support, and longevity. |

Ready to Eliminate Foot Pain for Your Entire Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-comfort, durable work footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered with the precise fit, supportive materials, and moisture-management features detailed in this guide.

We help you provide superior comfort that boosts productivity and reduces downtime. Let's discuss creating the perfect footwear solution for your market.

Contact our experts today for a consultation!

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- Are oil-resistant boots also waterproof? Don't Confuse These Two Critical Safety Features

- How does the size of women's work boots compare to men's? The Key to a Safe, Anatomically Correct Fit

- Why are heavy duty work boots important in high-risk environments? Essential PPE for Ultimate Safety

- What is the purpose of insulation in work boots? Essential for Warmth and Safety in Cold Conditions

- How does flexibility compare among PVC, neoprene, and rubber work boots? Find Your Perfect Fit for All-Day Comfort

- What features should junk removal workers look for in work boots? A Guide to Safety & Comfort

- What are some common toe shapes in Western boots? A Guide to Fit, Style, and Comfort

- What is a working boot? Your Essential Guide to Foot Safety and Durability