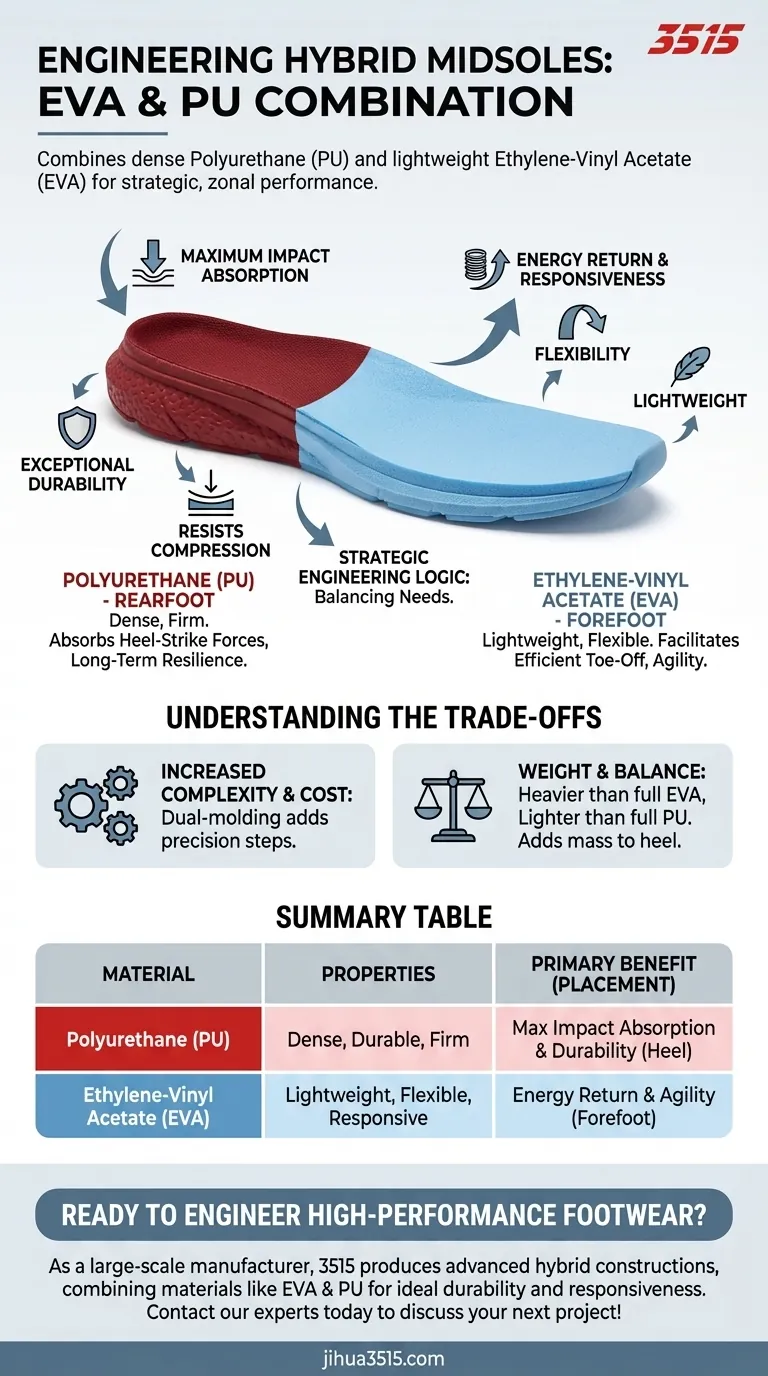

In advanced footwear design, combining Ethylene-Vinyl Acetate (EVA) and Polyurethane (PU) in a single midsole is a strategic engineering choice. This is typically achieved by placing the dense, durable PU in the rearfoot (heel) and the lighter, more flexible EVA in the forefoot. This zonal construction aims to leverage the distinct advantages of each material where they are most needed in the gait cycle.

The core principle behind a hybrid EVA/PU midsole is not to simply mix materials, but to strategically place them. This creates a shoe that offers maximum impact absorption and durability in the heel without sacrificing the lightweight responsiveness required for an efficient toe-off.

The Strategic Purpose of Hybrid Midsoles

Combining midsole materials is a solution to a fundamental engineering problem: no single foam can be both maximally durable and maximally lightweight and responsive. A hybrid design seeks to provide the best of both worlds by assigning a specific job to each material based on its location in the shoe.

Understanding Polyurethane (PU): The Shock Absorber

Polyurethane (PU) is a dense, heavy, and firm foam. Its key advantage is its exceptional resistance to compression over time. This means it doesn't "pack out" or flatten as quickly as other foams.

This durability makes it the ideal material for the heel area of the shoe. The heel endures the highest impact forces during a foot strike, and PU’s ability to consistently absorb this shock without degrading is its primary function in a hybrid design.

Understanding EVA: The Responsive Engine

Ethylene-Vinyl Acetate (EVA) is significantly lighter and more flexible than PU. It provides a softer, more cushioned, and "bouncier" feel underfoot.

This makes EVA perfectly suited for the forefoot. This part of the foot requires flexibility for a natural toe-off, and the lighter weight reduces the energy required to lift the foot through each step.

The Engineering Logic: Heel vs. Forefoot

The specific placement of these materials directly corresponds to the biomechanics of a typical stride. The initial heel-strike demands robust impact absorption and durability, which is PU's specialty.

Conversely, the final push-off phase from the ball of the foot and toes requires flexibility and energy return. Placing lightweight EVA in the forefoot facilitates this motion, making the shoe feel less cumbersome and more agile.

Understanding the Trade-offs

While innovative, this hybrid construction is not without its compromises. Acknowledging them is key to understanding when this design is truly appropriate.

Increased Complexity and Cost

Manufacturing a midsole with two different materials is inherently more complex than molding a single slab of foam. This dual-molding or assembly process adds steps and precision requirements, which often translates to a higher cost for the final product.

Weight and Balance

A hybrid midsole is heavier than a full EVA midsole but lighter than a full PU one. While it strategically places the heavier PU in the heel, it still adds overall mass compared to the lightest racing-style shoes.

Making the Right Choice for Your Goal

The decision to choose a shoe with a hybrid midsole depends entirely on your intended activity and priorities.

- If your primary focus is maximum durability and impact protection: A shoe with a PU component in the heel is an excellent choice, especially for hiking, work boots, or high-mileage running.

- If your primary focus is the lightest possible weight: A shoe made entirely of a modern, high-performance EVA foam will likely serve you better, particularly for racing or speed-focused activities.

- If your primary focus is balanced, all-around performance: A hybrid EVA/PU midsole offers a superb compromise, providing long-lasting heel protection and a responsive feel for daily training or versatile use.

Understanding this material science allows you to select footwear engineered precisely for your intended use.

Summary Table:

| Midsole Material | Key Properties | Strategic Placement in Shoe | Primary Benefit |

|---|---|---|---|

| Polyurethane (PU) | Dense, Durable, Firm | Heel (Rearfoot) | Maximum impact absorption & long-term durability |

| Ethylene-Vinyl Acetate (EVA) | Lightweight, Flexible, Responsive | Forefoot | Energy return & agility for toe-off |

Ready to engineer high-performance footwear with perfectly balanced midsoles?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including advanced hybrid constructions that strategically combine materials like EVA and PU.

We can help you create footwear that delivers the ideal blend of durability and responsiveness for your target market. Contact our experts today to discuss your next project!

Visual Guide

Related Products

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

People Also Ask

- What is the necessity of employing SVR for footwear design mapping? Precision Modeling for Modern Manufacturing

- What is the application value of modified footwear in simulating aging? Advanced Solutions for Balance Simulation

- What are the key functional features of Western riding boots? Unlock Superior Safety and Performance

- How does an industrial-grade piezoelectric ultrasonic transducer provide a non-injurious defense? Safe Canine Deterrence

- What are the advantages of using a multi-point array-style plantar pressure monitoring system in smart diagnostic insoles?

- How do mechanical knob-based tightening systems contribute to precise shoe collar stiffness? Master Footwear Engineering

- What type of physical protection do Disposable Cover Shoes provide? Master Clinical Infection Control Protocols

- When should parts of riding boots be replaced? A Guide to Safety and Performance