As a general rule, you should replace specific parts of your riding boots as soon as you notice functional wear. Replace soles and heels when they become unevenly worn, and immediately replace frayed laces or malfunctioning zippers, as these present an immediate safety risk during a ride. A professional cobbler can often handle these repairs to extend the lifespan of an otherwise sound pair of boots.

The decision to repair a boot part versus replacing the entire boot hinges on a single factor: structural integrity. While replacing worn components is smart maintenance, you must replace the entire boot once its core support and protective features are compromised.

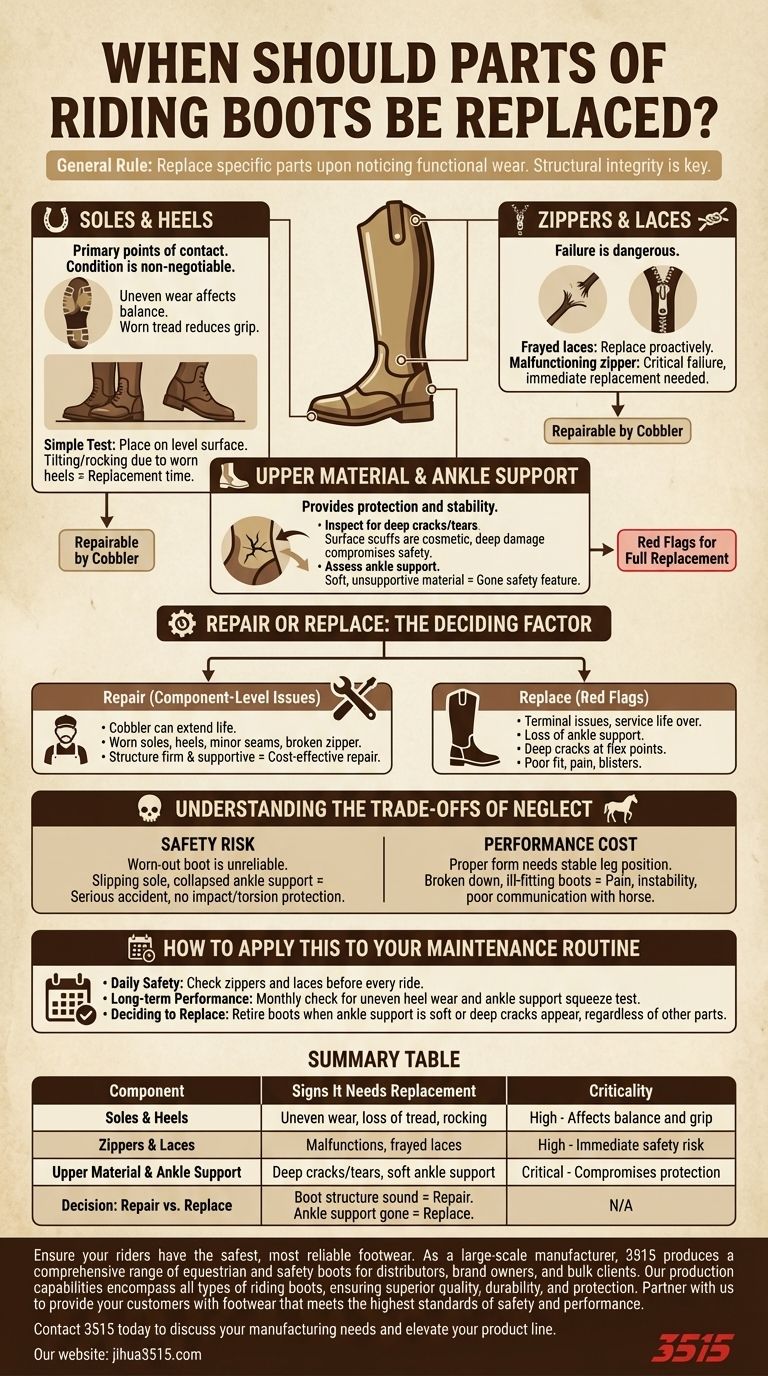

Assessing Critical Boot Components

Understanding which signs of wear are simple maintenance issues and which are critical failures is key to your safety and performance in the saddle.

The Foundation: Soles and Heels

The sole and heel are your primary points of contact with the stirrup and the ground. Their condition is non-negotiable.

Pay close attention to uneven wear patterns, which can affect your balance both in and out of the saddle. Worn-down tread or texture on the sole significantly reduces grip in the stirrup, increasing the risk of your foot slipping.

A simple test is to place your boots on a perfectly level surface. If they tilt or rock due to worn-down heels, it's time for a replacement.

The Fastening System: Zippers and Laces

A failure in your boot's fastening system can be distracting at best and dangerous at worst.

Frayed laces should be replaced proactively before they have a chance to snap. A malfunctioning zipper that sticks, separates, or won't stay up is a critical failure. This is not an issue to ignore, as a boot coming undone mid-ride can be a serious hazard.

The Structure: Upper Material and Ankle Support

This is where the boot provides protection and stability for your leg.

Inspect the leather or synthetic upper for deep cracks or tears, especially at flex points like the ankle. While surface-level scuffs are cosmetic, damage that penetrates the material compromises the boot's protective function.

Crucially, assess the ankle support. If the boot material has become soft and no longer provides firm, stabilizing support for your ankle, its most important safety feature is gone.

Repair or Replace: The Deciding Factor

Knowing when a simple fix is sufficient versus when it's time to invest in a new pair is a crucial judgment call.

When to Call a Cobbler

A skilled cobbler is your best asset for extending the life of your boots.

Component-level issues are ideal for repair. This includes replacing worn-down soles, rebuilding heels, stitching minor seam separations, and even replacing a broken zipper. If the boot's main structure is still firm and supportive, a repair is a cost-effective choice.

Red Flags for Full Replacement

Some issues are terminal and signal that the boot's service life is over.

The primary red flag is a loss of ankle support. If you can easily bend and twist the ankle area of the boot, it will not protect you in a fall. Likewise, deep cracks in the leather at flex points indicate the material itself has failed. Finally, if the boots no longer fit properly and cause pain, blisters, or discomfort, they must be replaced.

Understanding the Trade-offs of Neglect

Ignoring signs of wear isn't just about appearance; it has direct consequences for your safety and riding effectiveness.

The Safety Risk

A worn-out boot is an unreliable piece of safety equipment. A sole that slips from the stirrup can cause a serious accident. A boot with collapsed ankle support offers virtually no protection from impact or torsion in the event of a fall.

The Performance Cost

Proper riding form depends on a stable leg position, which starts with your boots. Boots that are broken down, ill-fitting, or lack support can contribute to pain and instability, preventing you from communicating clearly with your horse.

How to Apply This to Your Maintenance Routine

Use this checklist to make informed decisions about your equipment.

- If your focus is daily safety: Before every ride, give your zippers a quick test and glance at your laces for any signs of fraying.

- If your focus is long-term performance: Once a month, place your boots on a flat surface to check for uneven heel wear and squeeze the ankle area to assess its structural support.

- If your focus is deciding when to replace: When the ankle support becomes soft or deep cracks appear at flex points, it is time to retire the boots, regardless of the condition of the sole or zipper.

Ultimately, viewing your riding boots as critical safety equipment is the key to making the right maintenance decisions.

Summary Table:

| Component | Signs It Needs Replacement | Criticality |

|---|---|---|

| Soles & Heels | Uneven wear, loss of tread, boots rock on flat surface | High - Affects balance and stirrup grip |

| Zippers & Laces | Zipper malfunctions (sticks, separates), frayed laces | High - Immediate safety risk |

| Upper Material & Ankle Support | Deep cracks/tears, soft ankle support that twists easily | Critical - Compromises protection |

| Decision: Repair vs. Replace | Boot structure is sound = Repair. Ankle support is gone = Replace. | N/A |

Ensure your riders have the safest, most reliable footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of equestrian and safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of riding boots, ensuring superior quality, durability, and protection. Partner with us to provide your customers with footwear that meets the highest standards of safety and performance.

Contact 3515 today to discuss your manufacturing needs and elevate your product line.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What specific functions do IMUs perform in footwear? Unlock Precision Motion Analysis with Integrated Sensors

- What is the significance of the netting process in MRP for footwear? Optimize Production & Reduce Material Waste

- What role do pressure-relief devices and custom insoles play in DFU? Expert Management for Diabetic Foot Ulcers

- What is the function of molecular depolymerization and repolymerization equipment? Powering Circular Footwear Manufacturing

- How do post-operative shoes and soft dressings protect a replaced joint? Ensure Implant Stability and Faster Recovery

- When might someone need prescription orthotics? Key Signs OTC Inserts Aren't Enough

- What is Neoprene and what are its properties? Discover its Versatility for Your Products

- Why are socks important for boot comfort? The Critical Role of Socks in Footwear Performance