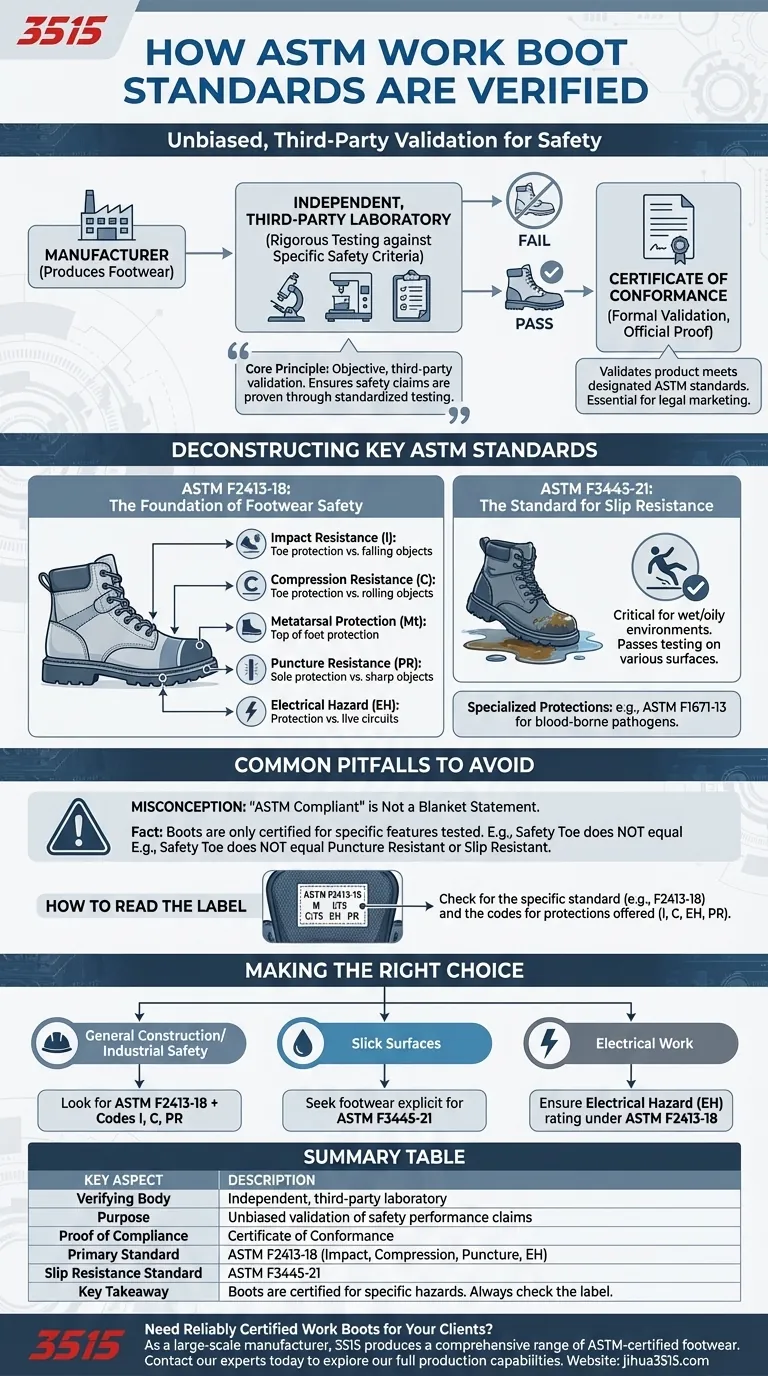

To be officially certified, ASTM standards for work boots are not verified by the manufacturer but by an independent, third-party laboratory. This lab conducts rigorous testing against specific safety criteria. If the footwear passes, the lab issues a formal Certificate of Conformance to validate that the product meets the designated ASTM standards.

The core principle of ASTM verification is objective, third-party validation. It ensures that a boot's safety claims are not just marketing, but are proven through standardized testing by an unbiased entity.

The Role of Independent Verification

Why Third-Party Testing is Critical

The requirement for an independent laboratory removes any potential conflict of interest. It ensures that the testing process is unbiased and that the results are credible.

This process provides a reliable benchmark for employers and workers, guaranteeing that the protective footwear provides the level of safety advertised.

The Certificate of Conformance

The output of this verification process is the Certificate of Conformance. This document is the official proof that a specific model of footwear was tested and met the performance requirements of a particular standard.

Manufacturers rely on this certificate to legally and ethically market their boots as compliant with ASTM standards.

Deconstructing the Key ASTM Standards

ASTM does not offer a single, all-encompassing certification. Instead, boots are tested and certified for specific hazards. Understanding these core standards is essential to selecting the right footwear.

ASTM F2413-18: The Foundation of Footwear Safety

This is the primary standard for protective footwear. It establishes the minimum requirements for performance in several key areas.

Boots certified under ASTM F2413-18 are tested for:

- Impact Resistance (I): Protection for the toe area against falling objects.

- Compression Resistance (C): Protection for the toe area against rolling objects.

- Metatarsal Protection (Mt): Protection for the top of the foot.

- Puncture Resistance (PR): Protection for the sole against sharp objects.

- Electrical Hazard (EH): Protection against accidental contact with live electrical circuits.

ASTM F3445-21: The Standard for Slip Resistance

This standard specifically governs the slip resistance of footwear. It is a critical certification for work environments where wet or oily surfaces are common.

A boot must pass laboratory testing on various floor surfaces under controlled conditions to earn this certification.

Specialized Protections

Other, more specific standards exist for unique workplace hazards. For example, ASTM F1671-13 outlines a test method for resistance to blood-borne pathogens, a crucial feature for first responders or healthcare workers.

Common Pitfalls to Avoid

"ASTM Compliant" is Not a Blanket Statement

A common mistake is assuming that an "ASTM-certified" boot protects against all possible hazards. This is incorrect.

A boot is only certified for the specific features it was tested for. A boot with a certified safety toe (ASTM F2413-18 I/75) is not automatically puncture-resistant (PR) or slip-resistant (ASTM F3445-21).

How to Read the Label

The official ASTM label, typically found on the boot's tongue, is your guide. It will list the specific standard (F2413-18) followed by the codes for the protections it offers (e.g., I/75, C/75, EH, PR).

Always check this label to confirm the boot has the exact protections you need for your work environment.

Making the Right Choice for Your Goal

To ensure you have the correct protection, you must match the boot's specific certifications to your workplace hazards.

- If your primary focus is general construction or industrial safety: Look for the ASTM F2413-18 label and verify it includes codes for Impact (I), Compression (C), and Puncture Resistance (PR).

- If your primary focus is working on slick surfaces: Specifically seek out footwear that explicitly states it meets the ASTM F3445-21 standard for slip resistance.

- If your primary focus is electrical work: Ensure the boot is rated for Electrical Hazard (EH) under ASTM F2413-18 and has no conductive components.

Ultimately, understanding the verification process empowers you to look beyond marketing and choose footwear based on proven, objective safety data.

Summary Table:

| Key Aspect | Description |

|---|---|

| Verifying Body | Independent, third-party laboratory |

| Purpose | Unbiased validation of safety performance claims |

| Proof of Compliance | Certificate of Conformance |

| Primary Standard | ASTM F2413-18 (Impact, Compression, Puncture, EH) |

| Slip Resistance Standard | ASTM F3445-21 |

| Key Takeaway | Boots are certified for specific hazards, not all hazards at once. Always check the label. |

Need Reliably Certified Work Boots for Your Clients?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified footwear for distributors, brand owners, and bulk clients. We ensure every pair meets the required safety standards through rigorous third-party verification, providing you with the certified proof and peace of mind your customers demand.

Let's discuss your specific needs: Contact our experts today to explore our full production capabilities and find the right safety solutions for your market.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What features should agricultural workers look for in work boots? A Guide to Safety and Durability

- How do slip-on boots compare in terms of upkeep? Lower Maintenance for Everyday Wear

- When should you waterproof your work boots? The simple test for optimal protection.

- What causes blisters in work boots? The Real Culprits Behind Foot Pain

- How does nanotechnology improve composite toe work boots? Achieve Lighter, More Comfortable Protection

- Why are moc toe boots popular? The Perfect Blend of Rugged Durability and Timeless Style

- What are the benefits of easy-to-clean farming and gardening boots? Boost Efficiency, Safety & Durability

- What are safety trainers and how do they differ from safety boots? Choose the Right Footwear for Your Job