Yes, most reputable oil-resistant safety boots do come with a manufacturer's warranty. However, the critical detail lies in what this warranty actually covers. These policies are designed to protect you from defects in manufacturing and materials, not from the inevitable wear and tear that comes from use in a demanding work environment.

While a warranty provides a safety net against manufacturing flaws, it does not cover the damage that occurs from normal job site use. True long-term value comes from understanding both the boot's built-in durability and the warranty's specific limitations.

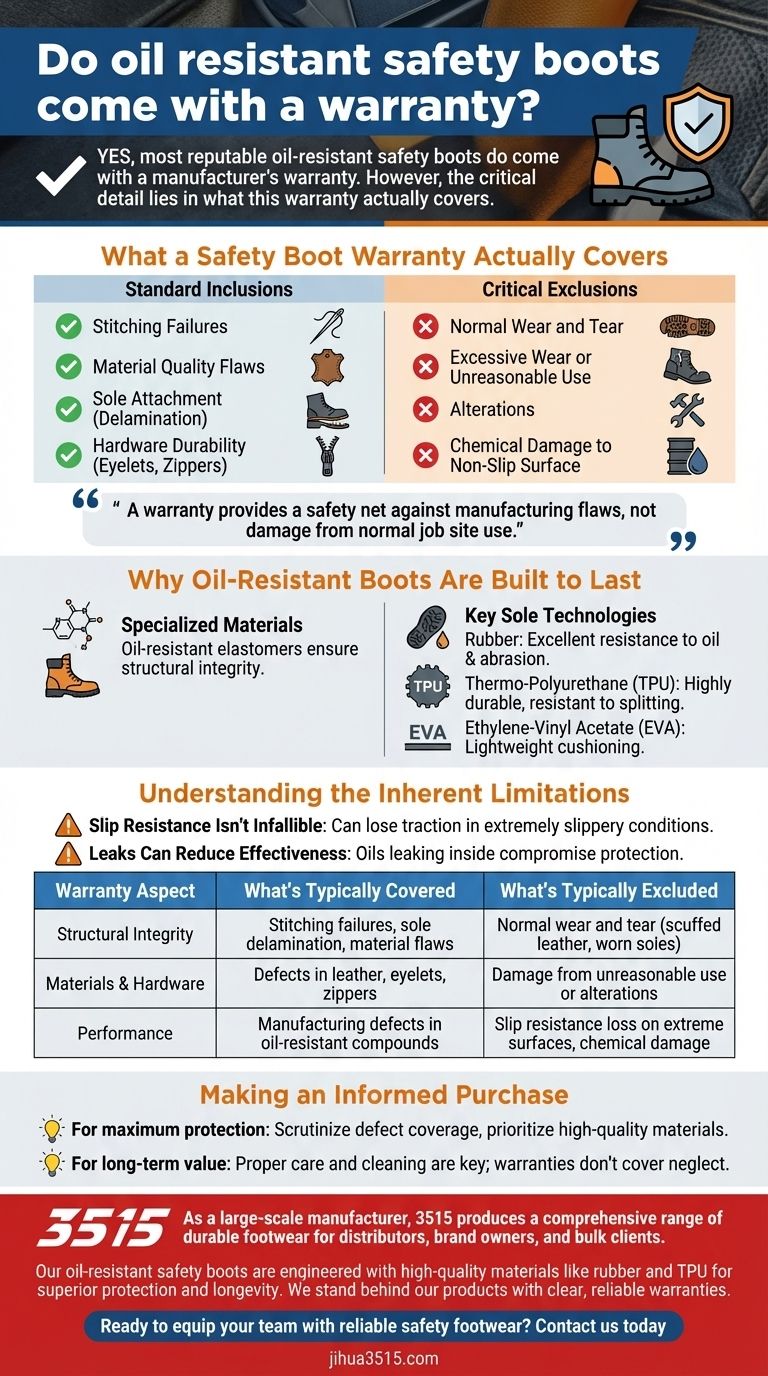

What a Safety Boot Warranty Actually Covers

A manufacturer's warranty is a promise of quality in the product's construction, not a guarantee of indestructibility. It serves to identify and resolve faults that occurred before the boots ever reached you.

Standard Inclusions

Most warranties focus on the structural integrity of the boot. Common covered items include defects related to:

- Stitching: Failures in the seams that hold the boot together.

- Material Quality: Flaws in the leather, fabric, or other upper materials.

- Sole Attachment: Separation of the outsole from the rest of the boot (delamination).

- Hardware Durability: Issues with eyelets, hooks, or zippers breaking under normal use.

Critical Exclusions

It is crucial to understand what is almost never covered. These exclusions typically involve damage resulting from use, not from a manufacturing error.

- Normal Wear and Tear: This includes worn-down soles, scuffs, and creases from walking and working.

- Excessive Wear or Unreasonable Use: Damage from using the boots for activities they were not designed for.

- Alterations: Any modification made to the boot after purchase will almost certainly void the warranty.

- Chemical Damage: Permanent damage to the non-slip surface caused by prolonged exposure to certain oils or solvents is not considered a defect.

Why Oil-Resistant Boots Are Built to Last

The reason warranties focus on defects is that these boots are specifically engineered for durability in harsh conditions. Their resilience comes from specialized materials designed to resist degradation.

The Role of Specialized Materials

Oil-resistant boots utilize advanced materials like oil-resistant elastomers in their construction. This ensures the sole and other components maintain their structural integrity and function even after repeated exposure to oil, often at high temperatures.

Key Sole Technologies

The outsole is the boot's primary point of contact with hazardous surfaces. Manufacturers use specific compounds to achieve both oil resistance and durability.

- Rubber: Offers excellent resistance to oil and abrasion.

- Thermo-Polyurethane (TPU): Known for being highly durable and resistant to splitting or cracking.

- Ethylene-Vinyl Acetate (EVA): Often used in the midsole for lightweight cushioning and comfort, complementing the tougher outsole.

Understanding the Inherent Limitations

Even the best-made boot has practical limits that a warranty does not address. Being aware of these ensures you have realistic expectations for performance and safety.

Slip Resistance Isn't Infallible

While designed with non-slip features, these boots can still lose traction in extremely slippery conditions, such as on thick spills or slick, wet surfaces. The "oil-resistant" feature is about material durability, not a guarantee against all slips.

Leaks Can Reduce Effectiveness

The boot's protective qualities are compromised if oils or other chemicals leak inside. This can damage internal components and reduce the boot's overall effectiveness and lifespan.

Making an Informed Purchase

Ultimately, the warranty is one part of a larger decision. Your goal is to select a boot that will perform and last, with the warranty acting as a backup for true product faults.

- If your primary focus is maximum protection: Scrutinize the warranty for its defect coverage, but place more importance on boots made with high-quality materials like durable rubber or TPU outsoles.

- If your primary focus is long-term value: Recognize that proper care and cleaning are your best tools, as the warranty will not cover damage from neglect or expected workplace wear.

Choosing the right safety boot is about investing in a tool engineered for your specific environment.

Summary Table:

| Warranty Aspect | What's Typically Covered | What's Typically Excluded |

|---|---|---|

| Structural Integrity | Stitching failures, sole delamination, material flaws | Normal wear and tear (scuffed leather, worn soles) |

| Materials & Hardware | Defects in leather, eyelets, zippers | Damage from unreasonable use or alterations |

| Performance | Manufacturing defects in oil-resistant compounds | Slip resistance loss on extreme surfaces, chemical damage |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients.

Our oil-resistant safety boots are engineered with high-quality materials like rubber and TPU for superior protection and longevity. We stand behind our products with clear, reliable warranties.

Ready to equip your team with reliable safety footwear? Contact us today to discuss your needs and benefit from our extensive production capabilities.

Visual Guide

Related Products

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Durable Moc Toe Wedge Sole Work Boots for Wholesale and Private Label

People Also Ask

- What are the consequences of not wearing safety shoes? Protect Your Feet from Severe Workplace Injuries

- What are the features of lace-up work boots? Achieve Maximum Safety and All-Day Comfort

- What type of footwear is required for mechanics? The Ultimate Guide to Garage Safety Boots

- What advice is given for selecting the right boots? A Step-by-Step Guide to Finding Your Perfect Fit

- What makes oilfield boots versatile for other industries? Unpacking Their Cross-Industry Value