Yes, certified composite toe boots are designed and tested to be compression resistant. They must meet the same stringent safety standards as steel toe boots to protect your feet from crushing injuries caused by heavy objects.

The core takeaway is that while both composite and steel toe boots meet the same official standard for compression resistance, they are not interchangeable. The choice between them depends entirely on the specific hazards and requirements of your work environment, as they offer fundamentally different secondary benefits and trade-offs.

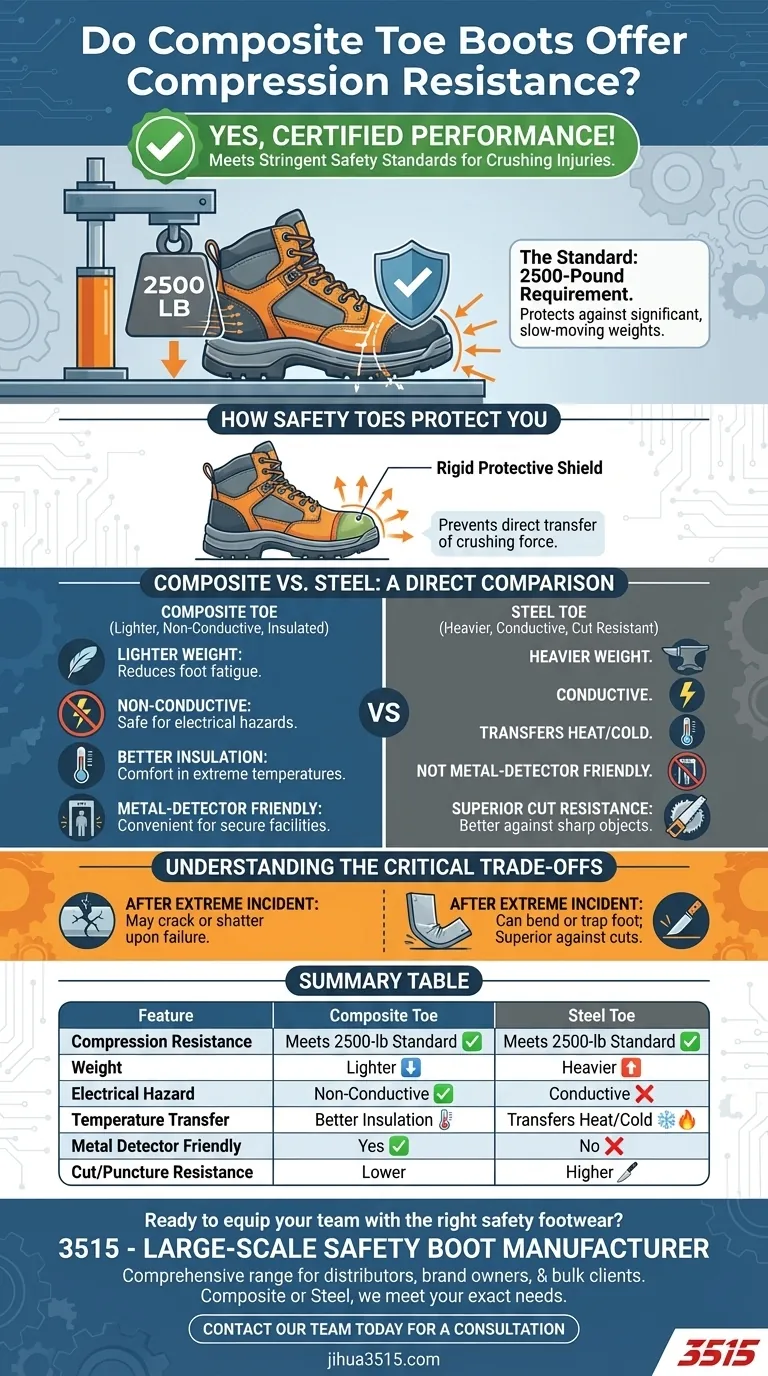

The Standard for Compression Resistance

To understand how composite toes function, it's essential to first understand the safety standard they are built to meet. This isn't about opinion; it's about certified performance.

The 2500-Pound Requirement

For a safety boot to be officially rated for compression resistance, its protective toe cap must withstand a compressive force of 2500 pounds.

This test ensures the toe box will not crush or deform in a way that would injure your foot when a significant, slow-moving weight is rolled onto it.

How Safety Toes Protect You

Both composite and steel toe caps work by creating a rigid, protective shield over your toes. This shield distributes the force of a compression or impact event, preventing the direct transfer of that crushing force onto your foot.

Composite vs. Steel: A Direct Comparison

While both materials achieve the same primary goal of compression resistance, their inherent properties create different advantages for the wearer.

The Weight Advantage

Composite materials, such as Kevlar, carbon fiber, or specialized plastics, are significantly lighter than steel. This reduces foot fatigue, making them ideal for mobile workers, tradespeople, or anyone who spends long hours on their feet.

Electrical and Thermal Properties

Composite materials are non-conductive to electricity. This is a critical safety feature for electricians or anyone working in environments with a risk of live electrical hazards.

Furthermore, they do not transfer cold or heat as readily as metal, offering better comfort in extreme temperature environments.

Convenience in Secure Environments

Because they contain no metal, composite toe boots are metal-detector friendly. This is a major benefit for frequent travelers, FIFO workers, or professionals working in secure facilities who must pass through security checkpoints regularly.

Understanding the Critical Trade-offs

Choosing composite toe boots involves accepting a specific set of trade-offs. Acknowledging these is crucial for making a safe decision.

Cut Resistance: The Steel Advantage

This is the most significant safety distinction. Steel toe caps offer a degree of cut resistance that composite materials do not.

If your work involves sharp, heavy materials or tools like chainsaws, a steel toe provides a superior level of protection against slicing or cutting hazards.

Impact Profile After an Incident

While both are tested for a single major impact, steel can sometimes bend or trap a foot after an extreme incident. Composite materials, on the other hand, are more likely to crack or shatter upon failure after an impact that exceeds their safety rating. Neither is designed for multiple major impacts.

Making the Right Choice for Your Goal

Selecting the correct safety footwear is about matching the boot's specific features to your daily risks and tasks.

- If your primary focus is electrical safety and lightweight mobility: Choose composite toe boots for their non-conductive properties and reduced foot fatigue.

- If your primary focus is maximum durability against cuts and punctures: Choose steel toe boots for their superior resistance to sharp objects and overall robustness.

- If you frequently pass through security checkpoints: Choose composite toe boots to avoid the inconvenience of metal detectors.

Ultimately, the right boot is the one that provides the best protection for the specific hazards you face every day.

Summary Table:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Compression Resistance | Meets 2500-lb standard | Meets 2500-lb standard |

| Weight | Lighter, reduces fatigue | Heavier |

| Electrical Hazard | Non-conductive | Conductive |

| Temperature Transfer | Better insulation | Transfers heat/cold |

| Metal Detector Friendly | Yes | No |

| Cut/Puncture Resistance | Lower | Higher |

Ready to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots for distributors, brand owners, and bulk clients. Whether your priority is the lightweight, non-conductive advantage of composite toes or the superior cut resistance of steel toes, our production capabilities encompass all types of safety footwear to meet your exact needs.

Let's discuss your requirements and get a quote for your next order.

Contact our team today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?