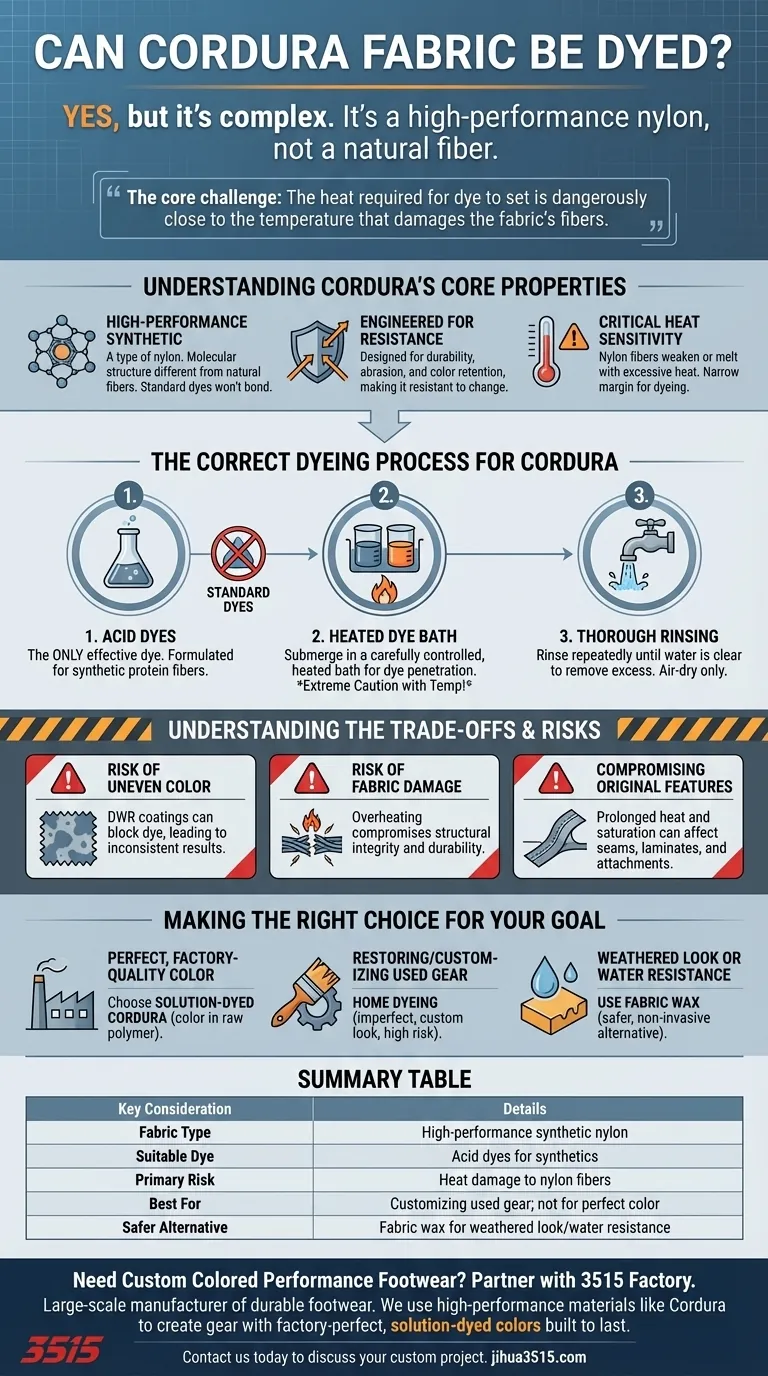

Yes, Cordura fabric can be dyed, but it requires a specialized approach due to its synthetic nature. Unlike natural fibers, Cordura is a type of high-performance nylon that will not accept standard dyes. The correct method involves using acid dyes specifically formulated for synthetics and a carefully controlled heated dye bath.

The core challenge of dyeing Cordura lies in a fundamental conflict: the heat required for the dye to set is very close to the temperature that can permanently damage the fabric's nylon fibers.

Understanding Cordura's Core Properties

To understand why dyeing Cordura is so specific, you must first understand the material itself. It is not a simple textile; it is an engineered fabric designed for extreme performance.

A High-Performance Synthetic

Cordura is a synthetic fabric, a type of nylon. Its molecular structure is fundamentally different from natural fibers like cotton or wool. Standard dyes cannot chemically bond with these synthetic polymers, rendering them ineffective.

Engineered for Resistance

The primary attributes of Cordura are its exceptional durability and resistance to abrasion, tearing, and fading. The fabric is explicitly designed to hold its color and withstand environmental stress, which inherently makes it resistant to the very changes you are trying to introduce with a new dye.

A Critical Sensitivity to Heat

While durable against abrasion, Cordura's nylon fibers are sensitive to high heat. As noted when ironing, excessive temperatures can cause the fibers to shrink, weaken, or even melt. This creates a significant challenge, as the most effective dyes for nylon require heat to set properly.

The Correct Dyeing Process for Cordura

Attempting to dye Cordura with the wrong materials or process will fail and may ruin your item. The correct method is precise and requires careful attention.

The Right Tool: Acid Dyes

The only effective dyes for materials like Cordura are acid dyes. These are formulated to bond with synthetic protein fibers like nylon. Using a standard all-purpose dye will only stain the surface and will wash out quickly, resulting in a faded, splotchy appearance.

The Heated Dye Bath Method

The standard process involves dissolving the acid dye in a water bath and heating it to a specific temperature. The Cordura item is then fully submerged and agitated in this heated bath for a period of time to allow the dye to penetrate and bond with the nylon fibers.

The Importance of Rinsing

After the dye bath, a thorough rinsing process is critical. You must rinse the fabric repeatedly until the water runs clear to remove any excess, unbonded dye. The item should then be air-dried, as a machine dryer's high heat could damage the material.

Understanding the Trade-offs and Risks

Dyeing Cordura is a high-risk modification. Before you begin, you must accept the potential for imperfect results or permanent damage.

Risk of Uneven Color

Many pieces of gear made from Cordura have durable water repellent (DWR) coatings or other chemical finishes. These coatings can block the dye from absorbing evenly, leading to a splotchy or inconsistent final color.

Risk of Fabric Damage

This is the most significant risk. The window between the temperature needed to set the dye and the temperature that damages nylon is very narrow. Overheating the fabric can compromise its structural integrity, reducing the very durability and strength for which Cordura is known.

Compromising Original Features

The dyeing process, which involves prolonged heat and water saturation, can impact other features of the item. It may affect seam tape, laminates, or other materials attached to the Cordura fabric.

Making the Right Choice for Your Goal

Before proceeding, clarify your objective. The right approach depends entirely on what you want to achieve.

- If your primary focus is a perfect, factory-quality color: Purchase gear made from solution-dyed Cordura, where the color is added to the raw polymer before it is even woven.

- If your primary focus is restoring or customizing used gear: Home dyeing is a possibility, but test on a hidden area first and be prepared for an imperfect, "custom" look rather than a uniform finish.

- If your primary focus is improving water resistance or achieving a weathered aesthetic: Consider using a fabric wax designed for synthetic gear as a safer, less invasive alternative to dyeing.

Ultimately, understanding Cordura's fundamental properties is the key to successfully and safely modifying your high-performance gear.

Summary Table:

| Key Consideration | Details |

|---|---|

| Fabric Type | High-performance synthetic nylon |

| Suitable Dye | Acid dyes for synthetics |

| Primary Risk | Heat damage to nylon fibers |

| Best For | Customizing used gear; not for perfect, uniform color |

| Safer Alternative | Fabric wax for a weathered look or improved water resistance |

Need Custom Colored Performance Footwear? Partner with 3515 Factory.

As a large-scale manufacturer, we produce a comprehensive range of durable footwear and boots for distributors, brand owners, and bulk clients. Our production capabilities include working with high-performance materials like Cordura to create gear with factory-perfect, solution-dyed colors that are built to last.

Let us handle the complexities of material science and manufacturing. Contact us today to discuss your custom footwear project and benefit from our expertise in bulk production.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Leather Business Casual Shoes with Dial Closure - Manufacturer of Comfort Dress Sneakers

- Wholesale Leather Derby Shoes Manufacturer | Customizable Business & Dress Footwear

- Wholesale Perforated Comfort Dress Shoes | Custom Derby Shoe Manufacturer

People Also Ask

- How do anatomical shoe last parameters impact foot health in nursing shoes? Engineering All-Day Comfort for Professionals

- What is the difference between waterproof and water-resistant shoes? Choose the Right Footwear for Your Needs

- What additional gear helps prevent cold feet in winter? Key Gear for Maximum Warmth

- Why is a multi-channel EMG system necessary for gait analysis? Unlock Precise Neuromuscular Control Insights

- What are the advantages of laser welding for piezoelectric energy harvesters? Achieve Precision and Durability

- Why must charging cables be completely disconnected from shoe-mounted sensors? Ensuring Safe Patient Neurorehabilitation

- What are the benefits of foam in shoes? Achieve Personalized Comfort & Support

- How does a three-axis magnetometer contribute to cooperative positioning? Accurate Heading in GNSS-Denied Zones