Yes, combat boots can generally be resoled, particularly if they are constructed with high-quality stitching or durable cementing. The feasibility of the repair is largely dictated by how the sole was originally attached to the upper material. While most reputable brands design their boots to be serviceable, inexpensive "disposable" models may not support the resoling process.

The Core Takeaway Extending the life of your combat boots through resoling is often a cost-effective alternative to buying new, provided the boots use stitched or standard cemented construction. Before discarding a worn pair, a consultation with a professional cobbler is the only definitive way to confirm if your specific brand and model can be saved.

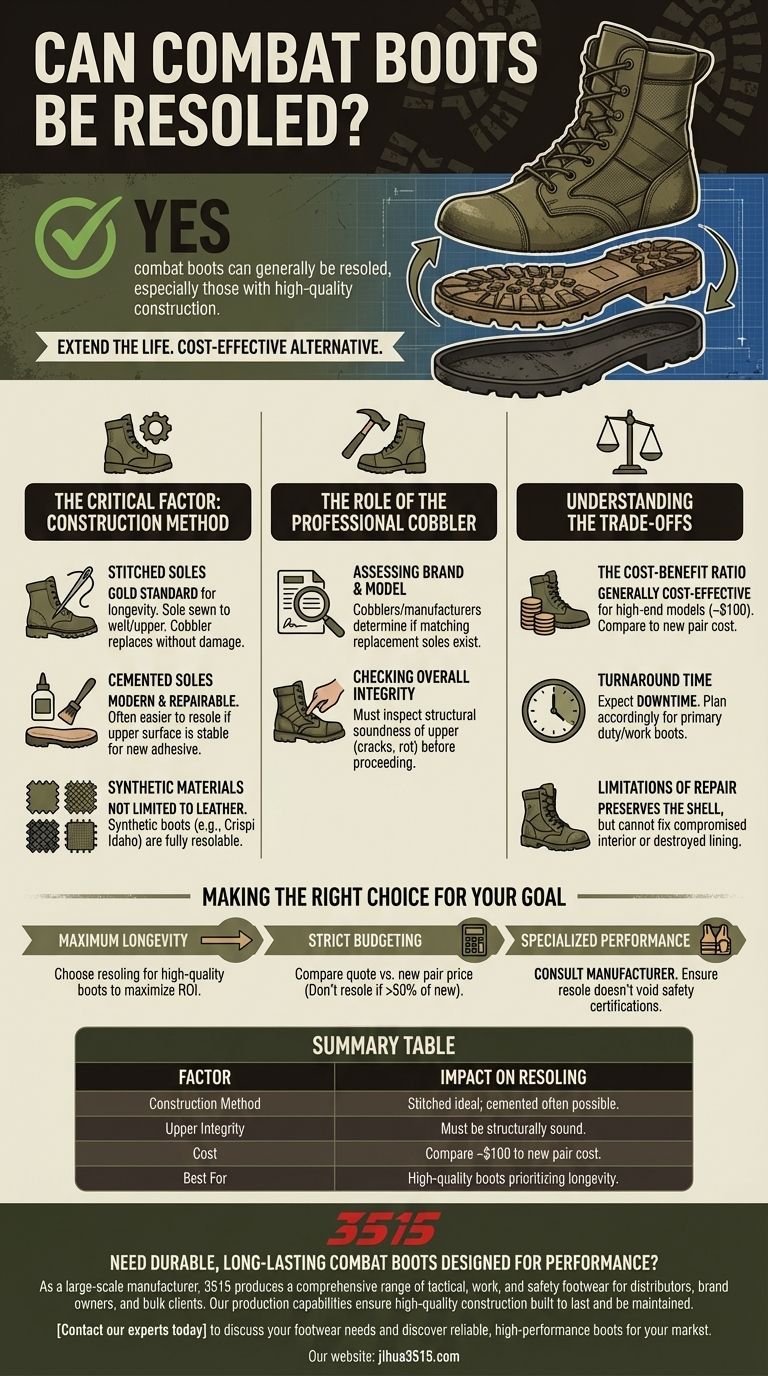

The Critical Factor: Construction Method

To determine if your boots are candidates for repair, you must look past the wear and tear and examine how the boot was built.

Stitched Soles

Boots featuring stitched construction are the primary candidates for resoling. Because the sole is physically sewn to the welt or upper, a cobbler can cut the stitching, remove the old sole, and sew on a new one without damaging the rest of the boot. This is often considered the gold standard for longevity.

Cemented Soles

Many modern combat boots use cemented (glued) construction. Contrary to popular belief, these can often be resoled as well. References indicate that boots with cemented soles are considered "easier to resole" in many contexts, provided the upper material provides a stable surface for the new adhesive to bond with.

Synthetic Materials

You are not limited to full leather boots. Synthetic material boots, such as the Crispi Idaho, are fully capable of being resoled. Even complex modern tactical boots mixing leather and synthetics can be repaired, maintaining their value despite the materials used.

The Role of the Professional Cobbler

While you can inspect the boot yourself, the final verdict belongs to an expert.

Assessing Brand and Model

Resoling depends heavily on the brand and model of your footwear. A professional cobbler or the original manufacturer can tell you if replacement soles exist that match your specific boot's specifications.

Checking Overall Integrity

A cobbler does more than look at the sole; they inspect the structural integrity of the upper. If the leather or synthetic upper is cracked or rotting, attaching a new sole may not be feasible or worth the investment.

Understanding the Trade-offs

Before committing to a resole, you must weigh the practical implications against simply purchasing a new pair.

The Cost-Benefit Ratio

Resoling is generally cost-effective, typically costing around $100 for high-end models. However, if your boots were inexpensive to begin with, the cost of repair might exceed the value of the boot.

Turnaround Time

While some services offer a quick turnaround, you will still be without your boots for a period of time. You need to account for this downtime if these are your primary duty or work boots.

Limitations of Repair

Not every element of the boot can be fixed. Resoling extends the lifespan of the traction and base, but it cannot fix a compromised interior or a destroyed lining. You are preserving the shell, not returning the boot to "factory new" condition inside and out.

Making the Right Choice for Your Goal

Deciding between repairing and replacing comes down to your priorities and the quality of your current gear.

- If your primary focus is maximum longevity: Choose resoling for high-quality, stitched, or reputable synthetic boots to maximize the return on your initial investment.

- If your primary focus is strict budgeting: Compare the quote from the cobbler against the price of a brand-new pair; do not resole if the repair costs more than 50% of a new replacement.

- If your primary focus is specialized performance: Consult the manufacturer first to ensure a third-party resole will not void safety certifications (common in firefighter or electrical hazard boots).

Your boots are tools; resoling is simply maintenance that keeps that tool functioning at a high level.

Summary Table:

| Factor | Impact on Resoling |

|---|---|

| Construction Method | Stitched soles are ideal; cemented soles are often possible. |

| Upper Integrity | The leather or synthetic upper must be structurally sound. |

| Cost | Typically ~$100; compare to the cost of a new pair. |

| Best For | High-quality boots where longevity is a priority. |

Need durable, long-lasting combat boots designed for performance?

As a large-scale manufacturer, 3515 produces a comprehensive range of tactical, work, and safety footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure high-quality construction that is built to last and can be maintained.

Contact our experts today to discuss your footwear needs and discover how we can provide reliable, high-performance boots for your market.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

People Also Ask

- What are the key features of the Boots Original Camo Red Desert? Designed for All-Day Comfort & Style

- Do jungle boots provide enough ankle support? Understanding the Trade-offs for Hot, Wet Climates

- How does high-precision 3D scanning equipment contribute to ergonomic optimization? Advanced Military Boot Development

- What are the characteristics of the nylon quarter side panels on combat boots? Lightweight, Breathable & Durable

- How does wind resistance enhance the performance of cold-weather boots? A Key to Superior Warmth & Safety

- What factors should be considered when choosing military boots for hiking? Durability vs. Weight for Your Terrain

- Why are military boots considered lightweight, and how does this benefit the wearer? Enhance Your Endurance & Mobility

- Do desert boots run true to size? Get the Perfect Fit with Our Expert Guide