First, I need to frame my role as a trusted technical advisor, someone who can objectively and expertly solve the user's core problem. My goal is to determine the best choice of boots based on the environment they'll be used in.

The user's core need seems to be differentiating between "water-resistant" and "waterproof" footwear. I'll need to explain the technical differences and implications for various work scenarios to empower the user to make a sound purchasing decision.

The provided references are a starting point, but they are repetitive and don't dig deep. My job will be to synthesize and expand upon this basic information. I'll need to get into the nitty-gritty of coatings, membranes, construction methods, and the impact of these on different professions (e.g., landscapers versus food processors). Importantly, I won't be inventing anything; I'll stick to explaining current technologies. I also need to stay laser-focused on the topic of water protection in work boots.

The tone will be calm, measured, and objective. I'll aim to use analogies to make technical concepts clear and radically improve the readability of the article with short paragraphs, bolding, and clear headings.

I've sketched out a clear structure. I'll kick things off with a bold statement directly answering the question: water-resistant boots are not suitable for all work environments. Then, I'll use a blockquote to highlight the problem: confusion around water resistance versus waterproofing can cause comfort and safety issues.

The main body will then delve into the technical differences, including concepts of breathability. I'll provide examples of jobs for which the different types of boots are suitable.

A section on trade-offs is essential; I'll discuss cost, breathability/comfort, and weight/flexibility.

The conclusion will provide actionable advice in a bulleted format, summarizing when to choose each type of boot. I'll end with an empowering sentence that ties it all together.

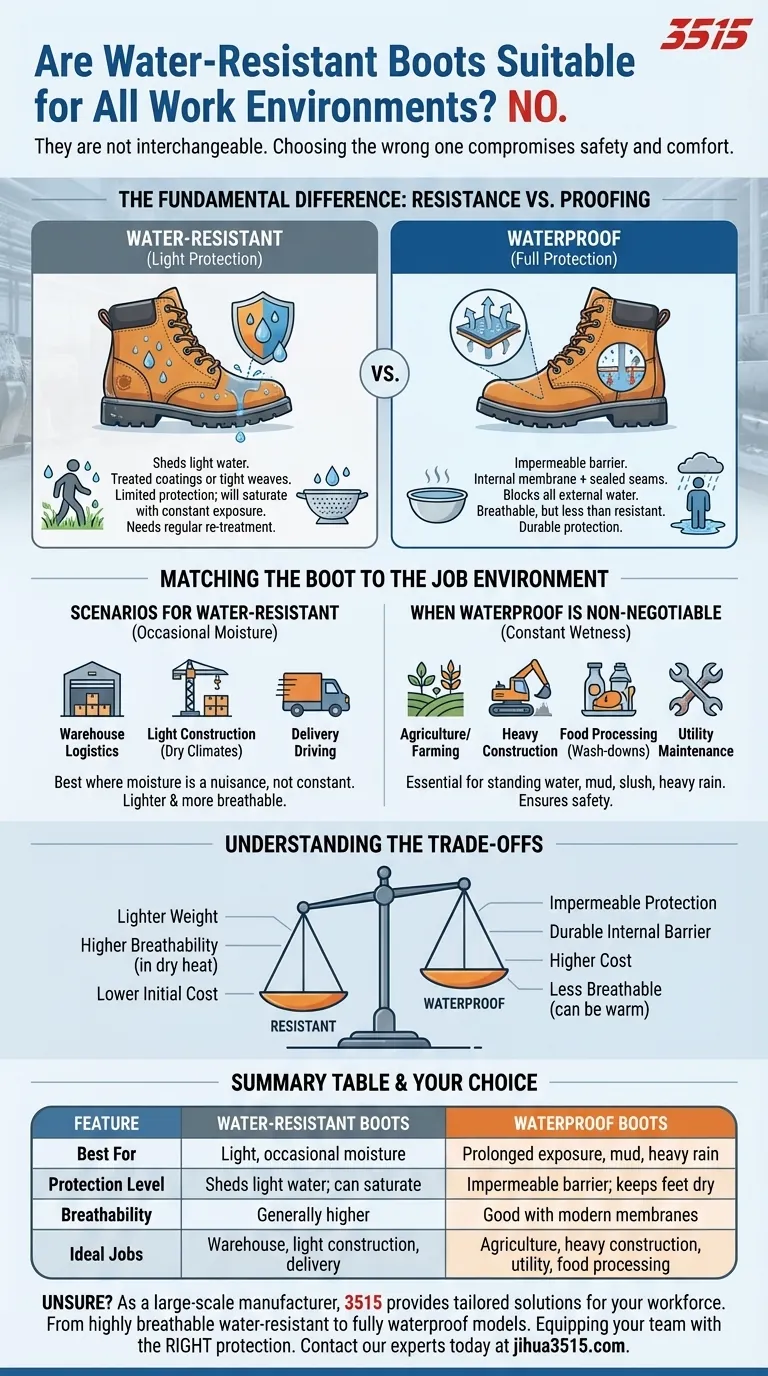

Essentially, I need to craft a comprehensive guide, answering the "why" behind the surface question using a scannable, authoritative format. I'm starting with the direct answer and backing it up with explanations and actionable advice. To be clear, no. Water-resistant boots are not suitable for all work environments. They are specifically designed to handle occasional and light exposure to moisture, such as walking through dewy grass or working through a brief shower. For any job involving prolonged contact with water, mud, or consistent wetness, they will fail to keep your feet dry.

The crucial mistake many professionals make is treating "water-resistant" and "waterproof" as interchangeable terms. In reality, they represent fundamentally different levels of protection, and choosing the wrong one can lead to discomfort, premature boot failure, and unsafe working conditions.

The Fundamental Difference: Resistance vs. Proofing

To select the right boot, you must first understand the technology that separates these two categories. The difference is not one of quality, but of engineering and purpose.

What "Water-Resistant" Truly Means

Water-resistant boots are typically made from materials like leather or tightly woven synthetics that have inherent properties to shed water. Often, they are treated with a surface coating that causes water to bead up and roll off.

This protection is limited. It can withstand light, intermittent exposure but will eventually become saturated under steady rain or when submerged. Think of it as a barrier that can be overwhelmed.

How "Waterproof" Achieves Full Protection

A truly waterproof boot creates an impermeable barrier. This is most often achieved with a dedicated waterproof, breathable membrane—a bootie-like liner built inside the boot.

This membrane contains microscopic pores that are too small for liquid water molecules to pass through but large enough for water vapor (sweat) to escape. This is then combined with sealed seams to ensure no water can penetrate any part of the boot's construction.

Matching the Boot to the Job Environment

The right choice is entirely dependent on the specific hazards and conditions of your daily work. A boot that is perfect for one job can be a serious liability in another.

Scenarios for Water-Resistant Boots

These boots excel where moisture is an occasional nuisance, not a constant state. They are often lighter and more breathable than their waterproof counterparts.

Consider them for roles like warehouse logistics, light construction in dry climates, or delivery driving, where you might encounter a sudden downpour or a small spill but are not consistently exposed.

When Waterproof is Non-Negotiable

If your work involves standing water, mud, slush, or constant, heavy rain, a waterproof boot is essential. There is no substitute for this level of protection.

Jobs in agriculture, heavy construction, food processing plants with frequent wash-downs, and utility maintenance demand fully waterproof footwear to ensure foot health and safety.

Understanding the Trade-offs

Choosing between water-resistant and waterproof involves balancing protection, comfort, and cost. Neither option is universally superior.

The Cost Factor

Waterproof technology, especially breathable membranes and sealed-seam construction, is more complex and expensive to manufacture. As a result, waterproof boots almost always carry a higher price tag.

Breathability and Comfort

While modern waterproof membranes are breathable, no system is perfect. In hot, dry conditions, a water-resistant boot will typically offer better ventilation, reducing sweat and increasing comfort. Wearing a fully waterproof boot in a desert environment, for example, would be unnecessary and uncomfortable.

Durability of Protection

The surface coatings that provide water resistance wear down over time and with abrasion. They require regular re-treatment to maintain their effectiveness. In contrast, the internal membrane of a waterproof boot provides lasting protection for the life of the boot, assuming it is not punctured.

Making the Right Choice for Your Work

To select the correct boot, you must honestly assess the level of water exposure you face daily.

- If your primary focus is working in mostly dry conditions with occasional light moisture: A water-resistant boot provides adequate protection while maximizing breathability and often saving on cost.

- If your primary focus is working in consistently wet, muddy, or rainy environments: A waterproof boot is the only reliable investment to keep your feet dry, safe, and comfortable all day.

- If your primary focus is versatility across changing conditions: A high-quality breathable waterproof boot offers the best all-around performance, managing both external water and internal sweat.

Choosing the right footwear is a critical decision for any professional, directly impacting your performance and well-being.

Summary Table:

| Feature | Water-Resistant Boots | Waterproof Boots |

|---|---|---|

| Best For | Light, occasional moisture (dew, brief rain) | Prolonged exposure (standing water, mud, heavy rain) |

| Protection Level | Sheds light water; can saturate | Impermeable barrier; keeps feet dry in wet conditions |

| Breathability | Generally higher | Good with breathable membranes |

| Ideal Jobs | Warehouse, light construction, delivery driving | Agriculture, heavy construction, utility work, food processing |

Unsure which boot is right for your team's environment?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. We have the expertise and production capabilities to provide the perfect solution—whether your workforce needs highly breathable water-resistant boots or fully waterproof models for harsh conditions.

Let us help you equip your team with the right protection.

Contact our experts today for a consultation on durable, reliable footwear tailored to your specific needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

People Also Ask

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene