Yes, firefighter boots have distinct downsides, primarily because they are highly specialized tools designed for extreme protection, not general use. The most significant drawbacks are their substantial weight, a necessary and often uncomfortable break-in period, and a high price point driven by their life-saving materials and construction.

The core trade-off with firefighter boots is simple: unparalleled protection comes at the cost of comfort, weight, and expense. Their design prioritizes surviving catastrophic conditions over the conveniences found in standard footwear.

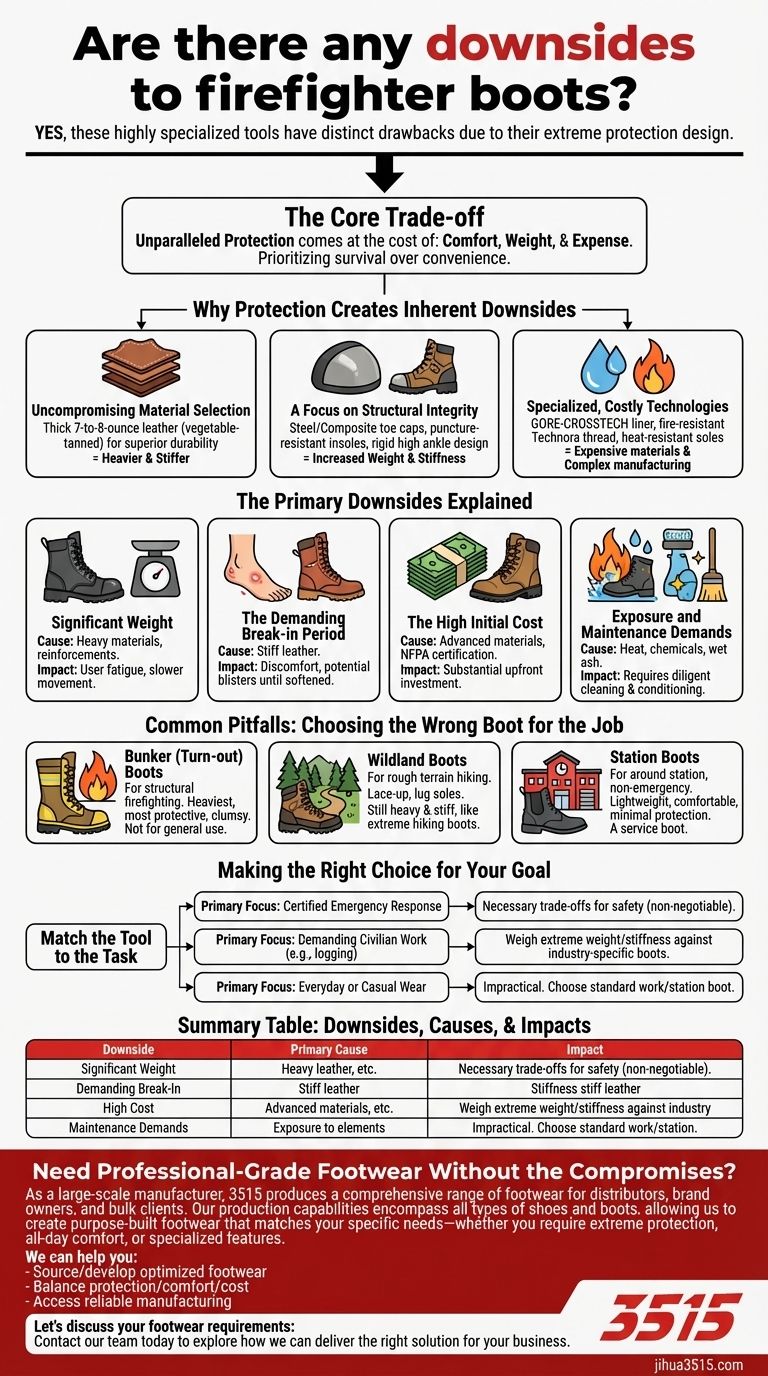

Why Protection Creates Inherent Downsides

Firefighter boots are not simply "heavy-duty." They are an engineered piece of personal protective equipment where every component is chosen for performance under duress, which directly creates their disadvantages.

Uncompromising Material Selection

The boots are built from materials that can withstand extreme heat and physical stress. This includes thick, 7-to-8-ounce leather, often premium vegetable-tanned hide, which is chosen for its superior durability and stiffness.

This contrasts sharply with the softer, more pliable leathers used in conventional work boots. The result is a boot that is inherently heavier and less flexible out of the box.

A Focus on Structural Integrity

Protection goes beyond heat resistance. Bunker boots require features like steel or composite toe caps and puncture-resistant insoles to guard against falling debris and sharp objects.

Furthermore, the high ankle design is rigid to provide maximum support and prevent sprains on unstable ground. This structural reinforcement is critical for safety but contributes directly to the boot's weight and stiffness.

Specialized, Costly Technologies

Modern firefighter boots incorporate advanced technologies that add to the price. Features like a GORE-CROSSTECH liner provide a waterproof barrier against water, chemicals, and contaminants.

Stitching often uses advanced, fire-resistant materials like Technora thread, and soles are made from heat-resistant compounds that will not melt. These non-negotiable safety features require expensive materials and complex manufacturing processes.

The Primary Downsides Explained

Understanding the design philosophy makes the specific drawbacks clear. These are not flaws but deliberate compromises made in the name of safety.

Significant Weight

The combination of heavy leather, reinforced soles, protective toe caps, and tall shafts makes firefighter boots significantly heavier than nearly any other type of footwear. This added weight can lead to fatigue over long periods of wear.

The Demanding Break-in Period

The stiff, durable leather required for protection does not conform to the foot easily. This results in a break-in period that can be lengthy and uncomfortable, potentially causing blisters or soreness until the leather softens and molds to the wearer's foot.

The High Initial Cost

Due to the specialized materials, rigorous safety testing standards (like NFPA certification), and advanced construction, firefighter boots are a significant investment. They are far more expensive than high-end work or hiking boots.

Exposure and Maintenance Demands

These boots are regularly exposed to steam, heat, wet ash (which creates lye), and caustic fire retardants. While built to withstand this, such harsh conditions can bake the leather and degrade materials over time, requiring diligent cleaning and conditioning to preserve their lifespan.

Common Pitfalls: Choosing the Wrong Boot for the Job

A frequent mistake is failing to recognize that "firefighter boot" is a broad category. The downsides vary significantly depending on the boot's specific purpose.

Bunker (or Turn-out) Boots

These are for structural firefighting. They are the heaviest, most protective, and often feature a pull-on design for speed. Their downsides of weight and clumsiness are most pronounced, making them completely unsuitable for anything but emergency response.

Wildland Boots

Designed for hiking over miles of rough terrain, these boots have a lace-up design for a secure fit and aggressive lug soles for traction. They are still very heavy and stiff but are built more like an extreme hiking boot.

Station Boots

These are lightweight, comfortable, and professional-looking boots meant for wear around the fire station or on non-emergency calls. They offer minimal protection and are essentially a form of service boot, lacking the trade-offs of their heavy-duty counterparts.

Making the Right Choice for Your Goal

To decide if firefighter boots are appropriate, you must match the tool to the task.

- If your primary focus is certified emergency response: The weight and cost are necessary trade-offs for your safety, which is non-negotiable.

- If your primary focus is demanding civilian work (e.g., logging, ranching): The durability is appealing, but you must weigh the extreme weight and stiffness against boots designed specifically for your industry, which may offer better long-term comfort.

- If your primary focus is everyday or casual wear: Firefighter boots are impractical and inappropriate due to their weight, stiffness, and cost. A standard work boot or station boot is a far better choice.

Ultimately, understanding these trade-offs ensures you choose a tool that supports your objective, rather than a burden that works against it.

Summary Table:

| Downside | Primary Cause | Impact |

|---|---|---|

| Significant Weight | Heavy leather, steel/composite toes, reinforced soles | User fatigue, slower movement |

| Demanding Break-In | Stiff, 7-8oz vegetable-tanned leather | Discomfort, blisters during initial use |

| High Cost | Advanced materials (GORE-TEX, Technora thread), NFPA certification | Substantial upfront investment |

| Maintenance Demands | Exposure to heat, chemicals, wet ash | Requires diligent cleaning and conditioning |

Need Professional-Grade Footwear Without the Compromises?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, allowing us to create purpose-built footwear that matches your specific needs—whether you require extreme protection, all-day comfort, or specialized features.

We can help you:

- Source or develop footwear optimized for your specific industry and use case

- Balance protection, comfort, and cost-effectiveness without unnecessary trade-offs

- Access reliable manufacturing with consistent quality and scalable production

Let's discuss your footwear requirements: Contact our team today to explore how we can deliver the right solution for your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- What are the advantages of using YOLOv4 for monitoring safety shoes? AI-Powered Real-Time Industrial Safety

- What is the safety footwear standard in Australia? Ensure AS 2210.3:2019 Compliance

- How do metatarsal guards enhance work shoe safety? Prevent Crushing Foot Injuries on the Job

- How does lightweight safety shoe technology reduce waist and shoulder injuries? Expert Ergonomic Insights

- What are the differences between internal and external metatarsal guards? Choose the Right Protection for Your Job

- How does constant temperature control affect the results of safety shoe slip resistance testing? Ensure Lab Precision

- What are the features of racing boots? Essential Protection for High-Speed Riding

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?