The definitive standard for safety footwear in Australia is AS 2210.3:2019. This standard outlines the minimum requirements and testing methods that all occupational safety footwear must meet to be considered compliant. It is the benchmark used by manufacturers, suppliers, and employers to ensure footwear provides a verified level of protection.

Understanding this standard is not about memorizing a number; it's about using a risk-based framework to match certified footwear protections against the specific hazards of a workplace. True safety comes from choosing the right tool for the job.

Why This Standard is Critical for Workplace Safety

The AS 2210.3:2019 standard serves as the foundation for foot protection in Australian workplaces. Its purpose is to create a clear, consistent, and reliable system for assessing safety footwear.

Establishing a Baseline of Trust

The standard provides a common language for everyone. It ensures that when a boot is sold as "safety footwear," it has passed a rigorous set of standardized tests for its claimed features.

This removes guesswork for employers and gives workers confidence in their personal protective equipment (PPE).

More Than Just a Steel Cap

While impact resistance is a core component, the standard covers a comprehensive range of potential workplace hazards. It creates classifications for various protective features beyond the classic toecap.

This ensures that footwear can be selected to protect against a multitude of risks, from punctures to electrical shocks.

A Framework for Compliance

Adherence to AS 2210.3:2019 is fundamental to meeting legal obligations under Work Health and Safety (WHS) laws. Providing compliant footwear is a key part of an employer's duty of care.

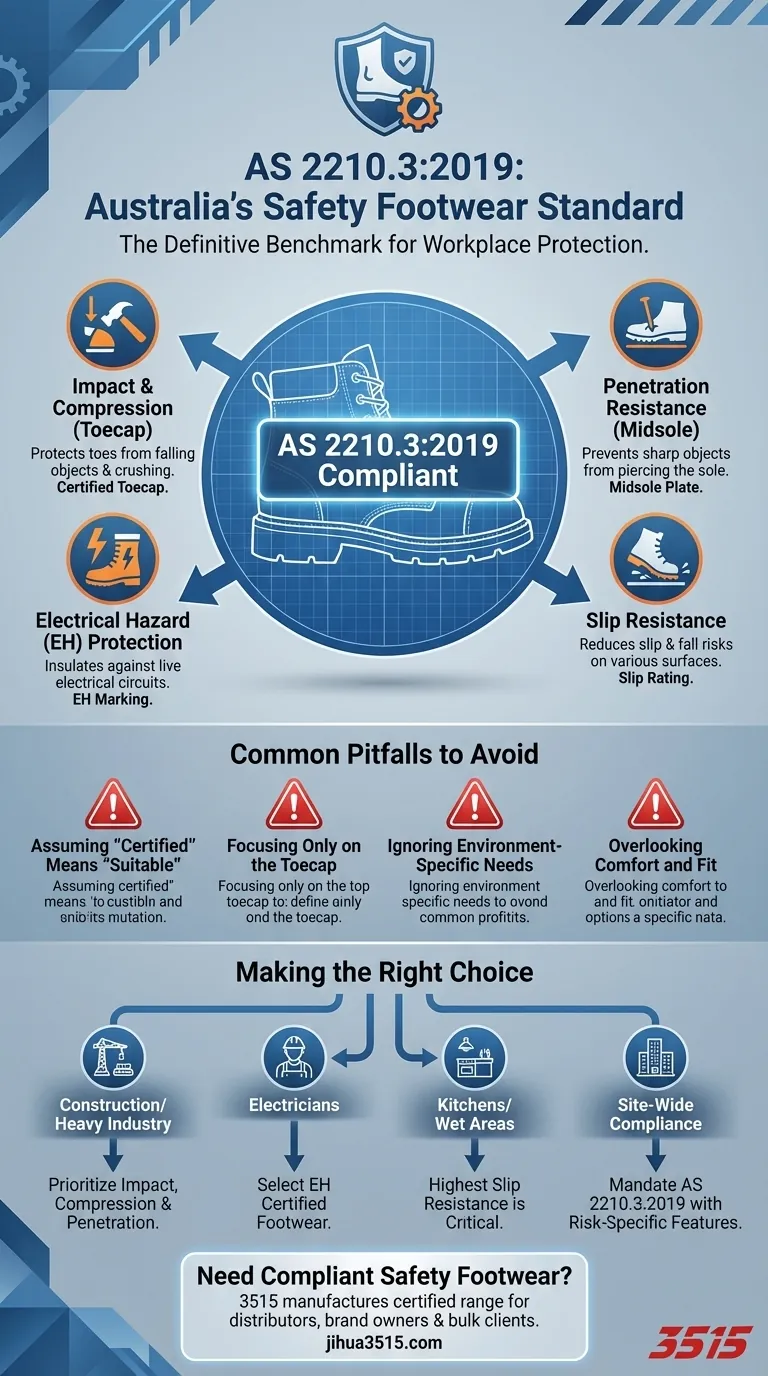

Decoding the Key Protections

The standard uses specific markings and classifications to denote the protections a boot offers. Understanding these core categories is essential for proper selection.

Impact and Compression Resistance

This is the most well-known feature, managed by a protective toecap. It is tested to ensure it protects the wearer's toes from the force of falling objects (impact) and crushing forces (compression).

Penetration Resistance

This feature involves a protective plate built into the midsole of the boot. It is designed to prevent sharp objects, such as nails or glass on the ground, from piercing the sole and injuring the foot.

Electrical Hazard Protection

Some footwear is specifically designed to be a secondary source of protection against accidental contact with live electrical circuits. These boots are made with non-conductive materials to insulate the wearer from the ground.

Slip Resistance

The standard includes testing protocols for the slip resistance of the boot's outsole on various surfaces. This is a critical factor in preventing one of the most common causes of workplace injury.

Additional Protective Features

The standard also provides classifications for other specialized protections, such as resistance to heat, water, and certain chemicals, or features like metatarsal guards that protect the top of the foot.

Common Pitfalls to Avoid

Choosing the wrong footwear, even if it's certified, can create a false sense of security. Being aware of common mistakes is as important as knowing the standard itself.

Assuming "Certified" Means "Suitable"

A boot being certified to AS 2210.3:2019 simply means it meets the minimum requirements for the specific features it was tested for. It does not mean it is appropriate for every single task or environment.

Focusing Only on the Toecap

The presence of a safety toe is just one aspect of protection. A worksite with a high risk of sharp objects on the ground requires penetration resistance, a feature not present in all safety boots.

Ignoring Environment-Specific Needs

A boot designed for a dry warehouse is fundamentally different from one needed on a wet, oily factory floor. Prioritizing the correct slip resistance and other environmental protections is non-negotiable.

Overlooking Comfort and Fit

A boot that meets every safety standard is useless if it's too uncomfortable to be worn correctly or consistently. Poor fit can lead to fatigue, blisters, and even non-compliance, entirely defeating the purpose of the PPE.

Making the Right Choice for Your Goal

Your selection process should begin with a risk assessment of the specific work environment. Use that assessment to determine which certified protections are mandatory.

- If your primary focus is construction or heavy industry: You must prioritize footwear with impact, compression, and penetration resistance.

- If your primary focus is working as an electrician: You must select footwear specifically certified for Electrical Hazard (EH) protection.

- If your primary focus is kitchens, food processing, or wet areas: The highest rating of slip resistance is your most critical requirement.

- If your primary focus is ensuring site-wide compliance: Mandate footwear that is clearly marked as compliant with AS 2210.3:2019 and specify the exact features required by your site's risk assessment.

By understanding the principles behind the standard, you can move beyond simple compliance and make an informed choice that ensures true safety.

Summary Table:

| Key Protection | Purpose | Standard Marking |

|---|---|---|

| Impact/Compression | Protects toes from falling objects & crushing | Toecap Certification |

| Penetration Resistance | Prevents sharp objects from piercing the sole | Midsole Plate |

| Slip Resistance | Reduces slip & fall risks on various surfaces | Slip Rating |

| Electrical Hazard | Insulates against accidental contact with live circuits | EH Marking |

Need AS 2210.3:2019 compliant safety footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities ensure your footwear meets exact Australian standards for impact, penetration, slip, and electrical hazards. Contact us today to discuss your specific requirements and get compliant, high-quality safety footwear delivered reliably.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

People Also Ask

- What are the primary benefits of safety Wellington boots? Unmatched Protection for Demanding Work

- What is unique about a carbon composite toe? Maximum Protection with Minimal Weight

- What role do industrial safety shoes play in improving the labor environment? Boost Safety and Reduce Worker Stress

- What is the significance of industrial sewing machines in footwear production? Ensuring Durability and Safety

- What are the main types of safety footwear? Choose the Right Protection for Your Workforce

- How do 2D and 3D pressure maps improve patient compliance? Visual Evidence for Protective Footwear Adherence

- What factors should employers consider when selecting safety footwear? A Guide to Workplace Safety

- In what ways does sensor integration technology enhance safety shoes? Revolutionize Worker Protection with Active Data