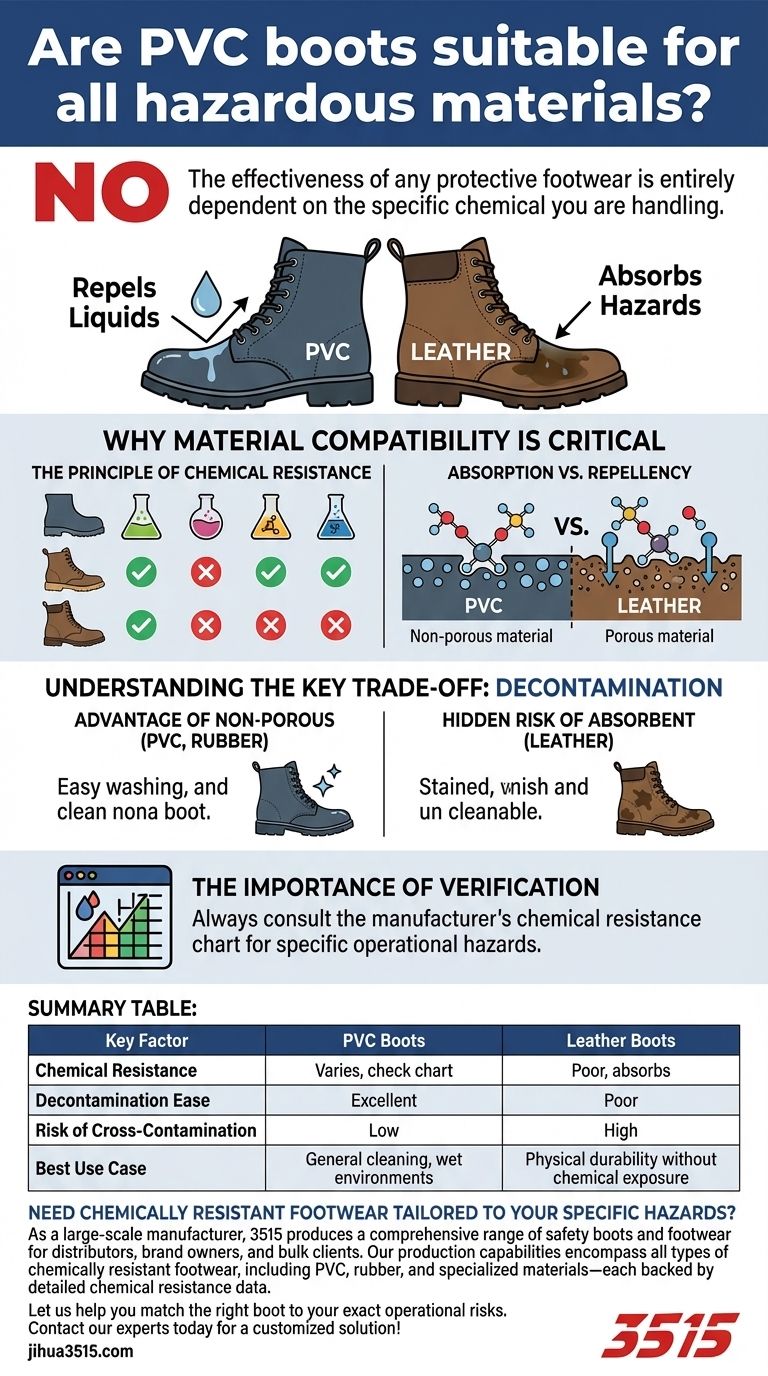

No, PVC boots are not suitable for all hazardous materials. The effectiveness of any protective footwear is entirely dependent on the specific chemical you are handling. You must always verify that the boot's material is chemically resistant to the specific hazards present in your work environment.

The core issue is not whether a boot is labeled "hazardous material safe," but whether its specific material—be it PVC, rubber, or something else—can withstand the specific chemicals it will be exposed to without degrading or absorbing them.

Why Material Compatibility is Critical

The Principle of Chemical Resistance

Protective footwear is designed to create an impermeable barrier. However, aggressive chemicals can permeate, degrade, or even dissolve materials that are not chemically compatible.

A boot that effectively blocks one acid might offer no protection against a powerful solvent. Assuming one material protects against all hazards is a dangerous oversight.

Absorption vs. Repellency

The material's surface properties determine how it interacts with contaminants. This is a critical factor for decontamination.

Materials like leather are porous and can absorb hazardous substances, especially if scuffed or damaged. This makes them extremely difficult to decontaminate fully, posing a risk of secondary exposure.

In contrast, non-porous materials like PVC and rubber are designed to repel liquids. This makes them far easier to clean and decontaminate, preventing the spread of hazardous materials.

Understanding the Key Trade-off: Decontamination

The Advantage of Non-Porous Materials

The primary advantage of rubber and PVC boots in hazardous environments is their ease of decontamination.

Their smooth, non-absorbent surfaces allow chemicals to be washed away thoroughly. This is essential for preventing cross-contamination and ensuring the wearer is not exposed to lingering chemicals after the initial task is complete.

The Hidden Risk of Absorbent Materials

Leather boots, while durable for physical work, become a liability when exposed to chemicals.

Once a substance is absorbed into the leather, it can be nearly impossible to remove. This not only risks ongoing exposure to the wearer but may require the boots to be disposed of after a single exposure event, increasing costs and waste.

The Importance of Verification

Never assume a boot is safe for your task. Always consult the manufacturer's chemical resistance chart.

This chart details how the boot material performs against a list of specific chemicals, providing crucial data on its suitability for your specific operational hazards.

How to Select the Right Footwear

Your choice of footwear must be driven by a precise risk assessment.

- If your primary focus is general cleaning or work with low-risk substances: PVC or rubber boots are an excellent default choice due to their waterproof nature and ease of cleaning.

- If your primary focus is handling specific, aggressive chemicals: You must consult the manufacturer's chemical resistance guide to verify that your boot's material is rated for that specific substance.

- If your primary focus is preventing cross-contamination: Always choose non-porous, easily-cleaned materials like rubber or PVC over absorbent materials like leather.

Ultimately, choosing the right protective footwear requires matching the specific material to the specific hazard.

Summary Table:

| Key Factor | PVC Boots | Leather Boots |

|---|---|---|

| Chemical Resistance | Varies by chemical; check manufacturer's chart | Generally poor; absorbs chemicals |

| Decontamination Ease | Excellent (non-porous, easy to clean) | Poor (porous, hard to decontaminate) |

| Risk of Cross-Contamination | Low (repels liquids) | High (absorbs and retains hazards) |

| Best Use Case | General cleaning, low-risk substances, wet environments | Physical durability (without chemical exposure) |

Need chemically resistant footwear tailored to your specific hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of chemically resistant footwear, including PVC, rubber, and specialized materials—each backed by detailed chemical resistance data.

Let us help you match the right boot to your exact operational risks.

Contact our experts today for a customized solution!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How were Wellington boots used in World War II? Essential Gear for Wet Battlefields

- What features make mid-calf Wellington boots ideal for everyday wear? Discover the Perfect Balance of Protection & Comfort

- How can children's feet be measured for Wellington boots? A Step-by-Step Guide for the Perfect Fit

- What certifications should you look for when purchasing sustainable Wellington boots? Choose GRS and FSC for verified eco-friendly footwear.

- What finishing touches are applied to gumboots before packaging? Ensure Quality and Durability

- Do wellies stretch over time? The Truth About Rubber Boot Fit & Comfort

- What are the drawbacks of rubber gardening shoes? Understanding the Trade-offs of Waterproof Footwear

- What are the UK sizes and corresponding insole lengths for children's wellies? A Simple Sizing Guide