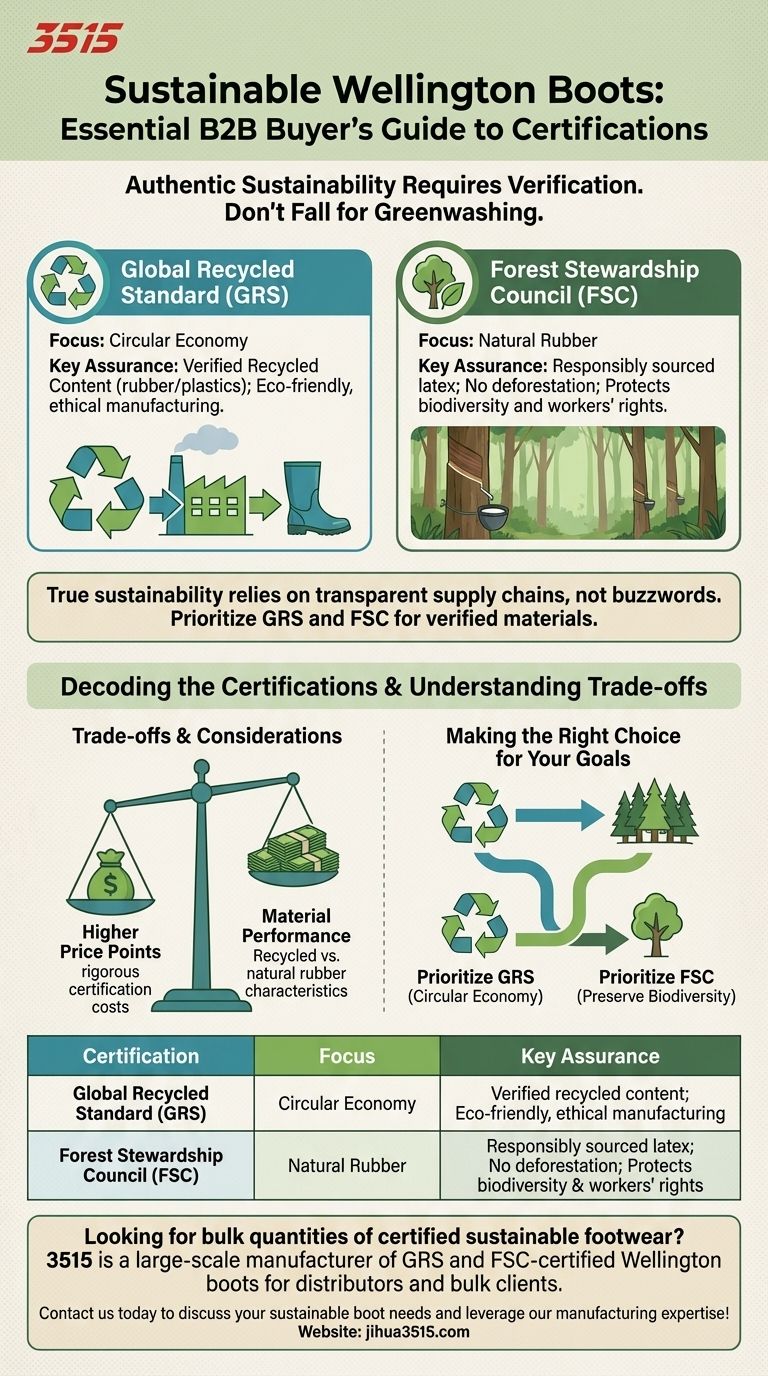

Authentic sustainability requires verification. When purchasing sustainable Wellington boots, the two most critical certifications to identify are the Global Recycled Standard (GRS) and the Forest Stewardship Council (FSC). These labels provide independent assurance that the materials in your footwear have been sourced responsibly and manufactured with genuine environmental consideration.

True sustainability in footwear relies on transparent supply chains, not just marketing buzzwords. Prioritizing GRS and FSC certifications ensures your boots are composed of verified recycled materials or responsibly managed natural rubber.

Decoding the Certifications

To ensure you are buying a genuinely sustainable product, you must understand what each certification specifically verifies regarding the boot's construction.

The Global Recycled Standard (GRS)

This certification focuses on the circular economy. It verifies that the boots contain a specific percentage of recycled content, such as recycled rubber or plastics.

Beyond just the raw material, GRS also tracks the entire supply chain. It ensures that the production process meets strict social and environmental requirements, minimizing chemical harm during manufacturing.

The Forest Stewardship Council (FSC)

This certification is essential if you are purchasing boots made from natural rubber. It guarantees that the latex used in the boots comes from responsibly managed forests.

FSC certification ensures that the rubber extraction does not contribute to deforestation or biodiversity loss. It also protects the rights of workers and indigenous communities in the regions where the rubber is tapped.

Understanding the Trade-offs

While certified boots are ethically superior, there are practical considerations to keep in mind regarding cost and availability.

Higher Price Points

Certifying a supply chain is a rigorous and expensive process for manufacturers. Consequently, boots carrying GRS or FSC labels often command a premium price compared to uncertified, mass-produced alternatives.

Material Performance

Sustainable materials have come a long way, but they can behave differently than virgin synthetic polymers.

For example, natural rubber (FSC) is incredibly waterproof and flexible but requires care to prevent cracking over time. Recycled synthetic blends (GRS) are durable but may lack the extreme elasticity of virgin rubber.

Making the Right Choice for Your Goals

Your choice of certification should align with your specific environmental priorities.

- If your primary focus is supporting the circular economy: Prioritize GRS certification to ensure your boots are diverting waste from landfills through the use of verified recycled materials.

- If your primary focus is preserving biodiversity and forests: Prioritize FSC certification to ensure the natural rubber in your boots is sourced without harming sensitive ecosystems.

By demanding these specific labels, you move beyond "greenwashing" and invest in footwear that aligns with your values.

Summary Table:

| Certification | Focus | Key Assurance |

|---|---|---|

| Global Recycled Standard (GRS) | Circular Economy | Verified recycled content (rubber/plastics); eco-friendly, ethical manufacturing |

| Forest Stewardship Council (FSC) | Natural Rubber | Responsibly sourced latex; no deforestation; protects biodiversity and workers' rights |

Looking for bulk quantities of certified sustainable footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of GRS and FSC-certified Wellington boots for distributors, brand owners, and bulk clients. Our production capabilities ensure you get high-quality, verified sustainable footwear that meets your environmental standards and volume requirements.

Contact us today to discuss your sustainable boot needs and leverage our manufacturing expertise!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- Is it advisable to manually stretch children's wellies? Protect Your Child's Foot Health and Boot Integrity

- What are the traditional and modern uses of wellington boots? From Military to Mainstream

- How can men's wellies be styled for different occasions? Master Casual, Outdoor & Festival Looks

- How are gumboots packaged and distributed? Ensure Product Integrity from Factory to Customer

- Why is it important to measure children's feet before buying wellies? Ensure Safety and Healthy Growth

- What are the key characteristics of rain boots? Essential Features for Total Dryness

- How can wellies enhance the experience at a music festival? Stay Dry, Comfortable, and Confident All Weekend

- What are the advantages of PVC boots? Get Lightweight, Waterproof Protection