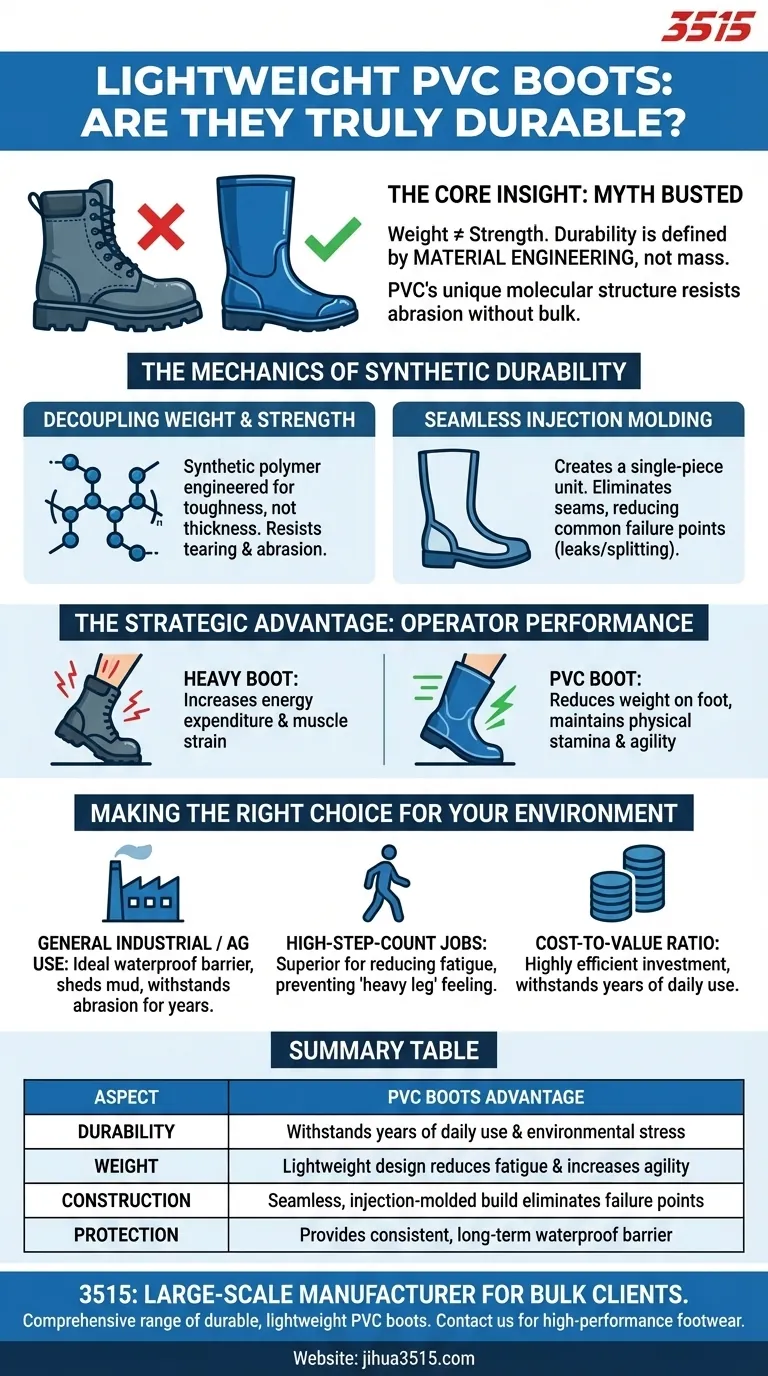

The correlation between weight and strength is a misconception. PVC (Polyvinyl Chloride) boots are definitively durable despite their lightweight profile. By utilizing advanced synthetic molding, these boots provide a high-strength barrier that withstands years of daily use without the bulk associated with traditional rubber footwear.

Core Insight: Durability in modern protective gear is defined by material engineering, not mass. PVC offers a unique molecular structure that resists abrasion and degradation, proving that heavy protection does not require a heavy boot.

The Mechanics of Synthetic Durability

Decoupling Weight from Strength

In traditional footwear, weight often equated to thickness, which was necessary for protection. PVC changes this equation.

Because PVC is a synthetic polymer, it can be engineered to be incredibly tough while remaining thin and light. This allows for a boot that resists tearing and abrasion without dragging down the wearer.

Withstanding Daily Abuse

The reference material confirms that PVC boots can endure "years of daily use without significant wear."

This longevity is due to the material's innate resistance to environmental stressors. Unlike organic materials that may rot or degrade when exposed to mud or water, PVC maintains its structural integrity over time.

The Role of Construction

Most PVC boots are manufactured using injection molding.

This creates a seamless, single-piece unit. Without seams—which are the most common failure points in multi-part boots—the likelihood of splitting or leaking is drastically reduced, further enhancing durability.

The Strategic Advantage of Lightweight Gear

Reducing Operator Fatigue

The "lightweight" aspect of PVC is not a compromise; it is a feature designed for human performance.

Heavy boots increase energy expenditure and muscle strain with every step. By reducing the weight on the foot, PVC boots help maintain the wearer's physical stamina throughout a shift.

Long-Term Protection

Durability extends beyond the boot simply not falling apart.

True durability means maintaining protective qualities over time. PVC provides consistent long-term protection, ensuring that the boot performs as well in year two as it did on day one.

Limitations to Consider

The Scope of "Durability"

While PVC is highly durable regarding general wear and abrasion, it is important to understand its specific properties.

"Years of use" assumes the boots are used within their intended design parameters. Extreme thermal environments or specific caustic chemicals outside standard ratings may impact the material differently than standard daily use.

Material Stiffness

PVC is a robust plastic, but its rigidity can vary.

While durable, the material acts differently than soft rubber. Users transitioning from softer materials should be aware that the durable exterior provides a different tactile feel during movement.

Making the Right Choice for Your Environment

To ensure you get the longevity promised by PVC, align your choice with your specific operational goals.

- If your primary focus is General Industrial or Agricultural Use: PVC is the ideal choice, offering a waterproof barrier that sheds mud and withstands abrasion for years.

- If your primary focus is Reducing Fatigue: The lightweight construction is superior for high-step-count jobs, preventing the "heavy leg" feeling associated with rubber.

- If your primary focus is Cost-to-Value Ratio: The ability to withstand years of daily use makes PVC a highly efficient investment for long-term outfitting.

Modern PVC proves that you do not need to sacrifice agility to ensure complete protection.

Summary Table:

| Aspect | PVC Boots Advantage |

|---|---|

| Durability | Withstands years of daily use, abrasion, and environmental stress |

| Weight | Lightweight design reduces operator fatigue and increases agility |

| Construction | Seamless, injection-molded build eliminates common failure points |

| Protection | Provides a consistent, waterproof barrier over the long term |

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, lightweight PVC boots for distributors, brand owners, and bulk clients. Our advanced injection molding technology ensures your footwear is built to last, offering the perfect balance of protection and comfort for industrial, agricultural, and safety applications. Ready to equip your team with high-performance footwear? Contact us today to discuss your specific needs and discover the 3515 advantage.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?