In many situations, yes. Composite toe boots are frequently more comfortable than their steel toe counterparts primarily because they are significantly lighter and do not conduct heat or cold. This reduction in weight can lead to less fatigue over a long workday, while their thermal properties keep your feet more comfortable in extreme temperatures.

The choice between composite and steel toe boots is not simply a matter of comfort versus safety. It's about matching the specific material properties of the boot to the unique hazards and daily demands of your specific work environment.

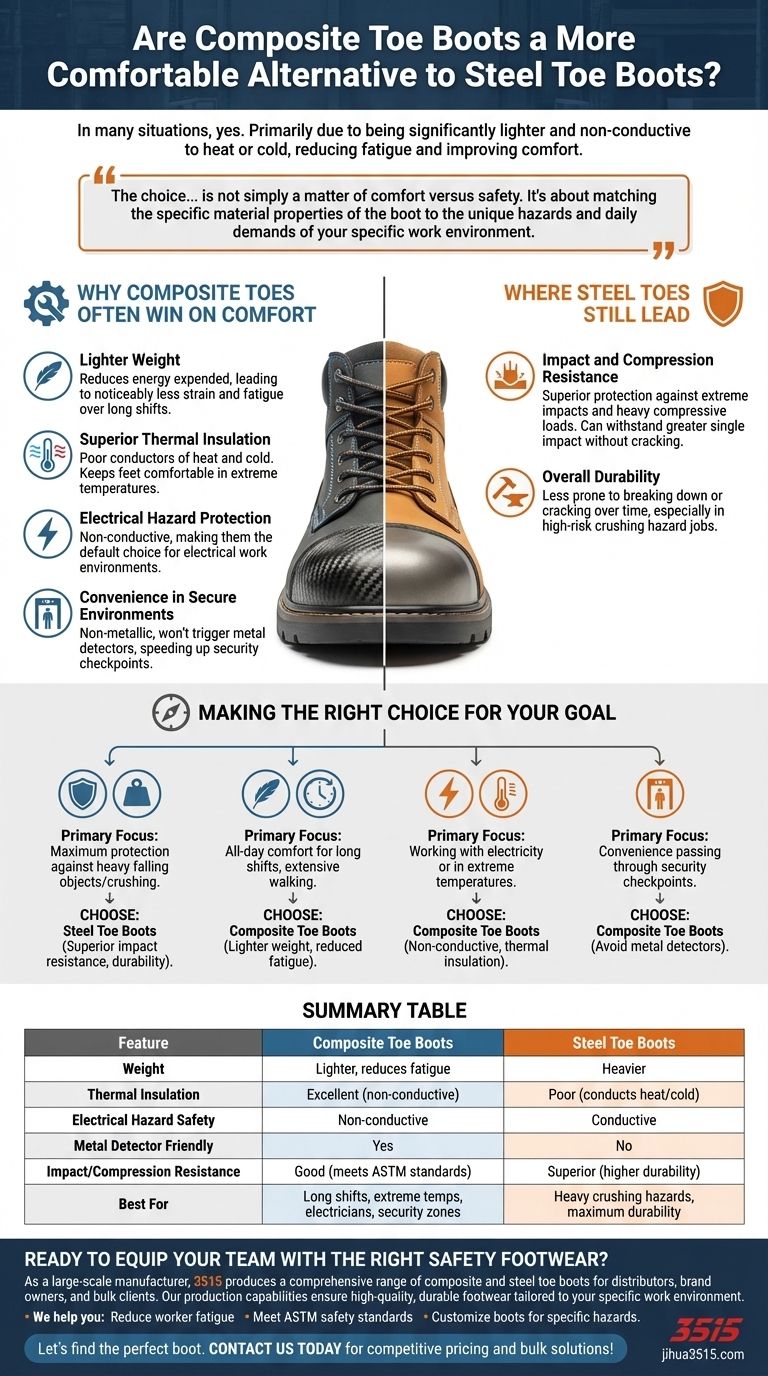

Why Composite Toes Often Win on Comfort

The argument for composite toe comfort comes down to material science. Instead of a single piece of steel, these caps are made from a blend of non-metallic materials like kevlar, carbon fiber, and specialized plastics.

The Impact of Lighter Weight

A lighter boot reduces the energy you expend with every step. Over an eight or ten-hour shift, this seemingly small difference compounds, leading to noticeably less strain and fatigue on your legs and feet.

Superior Thermal Insulation

Unlike metal, composite materials are poor conductors of heat and cold. This means in frigid weather, the cold isn't transferred directly to your toes, and in extreme heat, the toe cap won't become uncomfortably hot.

Electrical Hazard Protection

Because they contain no metal, composite toe boots are non-conductive. This makes them the default choice for electricians or anyone working in environments where contact with live electrical circuits is a potential hazard.

Convenience in Secure Environments

The non-metallic and non-magnetic nature of composite toes means they won't trigger metal detectors. This is a major convenience for workers who frequently pass through security checkpoints.

Understanding the Trade-offs: Where Steel Toes Still Lead

While composite materials offer clear advantages, steel remains the standard for a reason. It's crucial to understand where composite toe caps compromise in exchange for their comfort benefits.

Impact and Compression Resistance

Steel provides superior protection against extreme impacts and heavy compressive loads. While both types must meet the same fundamental ASTM safety standards, steel can withstand a greater single impact without cracking. A composite toe, under a force that exceeds its rating, is more likely to crack.

Overall Durability

Under consistent, heavy-duty use, steel is simply a more durable material. It is less prone to breaking down or cracking over time compared to composite materials, particularly in jobs involving a high risk of crushing hazards.

Making the Right Choice for Your Goal

The best boot is the one that correctly aligns with your job's specific risks and requirements.

- If your primary focus is maximum protection against heavy falling objects or crushing hazards: Choose steel toe boots for their superior impact resistance and durability.

- If your primary focus is all-day comfort for long shifts with extensive walking: Choose composite toe boots to benefit from their lighter weight and reduced fatigue.

- If your primary focus is working with electricity or in extreme hot or cold temperatures: Choose composite toe boots for their essential non-conductive and thermal insulating properties.

- If your primary focus is convenience when passing through security checkpoints: Choose composite toe boots to avoid the hassle of metal detectors.

Ultimately, understanding these core differences empowers you to select the right tool for the job, ensuring both safety and comfort.

Summary Table:

| Feature | Composite Toe Boots | Steel Toe Boots |

|---|---|---|

| Weight | Lighter, reduces fatigue | Heavier |

| Thermal Insulation | Excellent (non-conductive) | Poor (conducts heat/cold) |

| Electrical Hazard Safety | Non-conductive | Conductive |

| Metal Detector Friendly | Yes | No |

| Impact/Compression Resistance | Good (meets ASTM standards) | Superior (higher durability) |

| Best For | Long shifts, extreme temps, electricians, security zones | Heavy crushing hazards, maximum durability |

Ready to equip your team with the right safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of composite and steel toe boots for distributors, brand owners, and bulk clients. Our production capabilities ensure high-quality, durable footwear tailored to your specific work environment—whether you prioritize comfort, safety, or both.

We help you:

- Reduce worker fatigue with lighter composite options

- Meet ASTM safety standards without compromising on comfort

- Customize boots for electrical hazards, thermal extremes, or high-security areas

Let’s find the perfect boot for your needs. Contact us today for competitive pricing and bulk solutions!

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- Why are steel toe shoes important in workplaces with heavy items? Essential Protection for Industrial Safety

- What are the benefits of wearing steel toe boots? Maximum Impact Protection & Durability

- How do steel toe shoes protect workers in areas with large, movable machinery? Essential Safety Guide

- What steps can be taken to choose the right steel toe boots for comfort? A Guide to All-Day Wearability

- Is it true that steel toes can cause toes to get cut off? Debunking the Dangerous Myth

- Why is impact-resistant toe protection a core safety feature? Essential Protection for Heavy Loading

- When and where should steel toe boots be used? Ensure Maximum Impact Protection

- What are the different types of safety toes available in work boots? Choose the Right Protection for Your Job