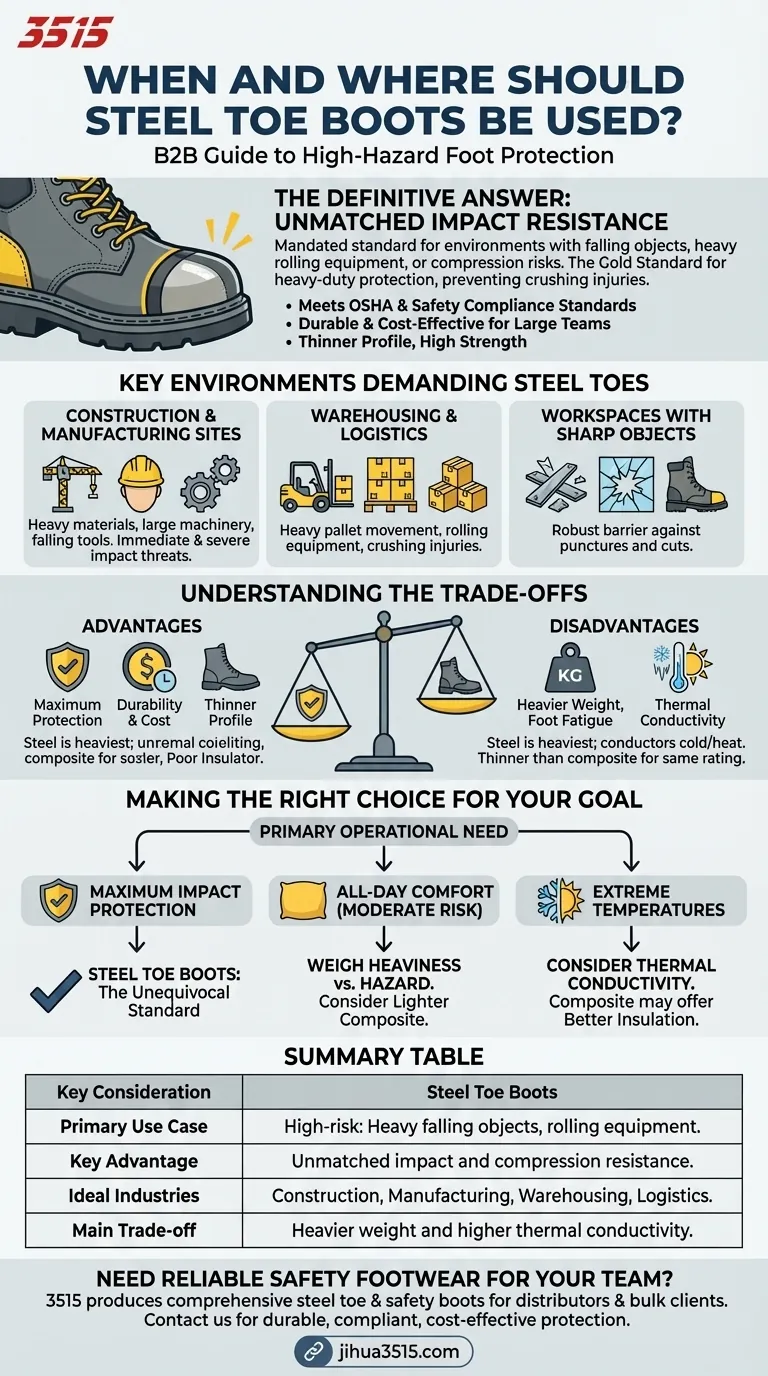

The definitive answer is clear: steel toe boots must be used in any environment where the primary risks are from falling objects, heavy rolling equipment, or compression. This makes them the mandated standard in industries like construction, manufacturing, and logistics, where foot protection against severe impact is the highest priority.

Choosing the right safety footwear is more than a simple compliance check. While steel toe boots offer the highest level of impact resistance, understanding their specific trade-offs in weight and thermal conductivity is critical for making an informed safety decision for your specific environment.

The Core Principle of Steel Toe Protection

Steel has long been the benchmark for safety footwear for a reason. Its fundamental properties provide a level of protection that is difficult to replicate with other materials.

Unmatched Impact Resistance

The defining feature of a steel toe boot is its ability to withstand extreme impact and compression. The reinforced steel cap is engineered to prevent crushing injuries from heavy falling objects or machinery.

This makes it the indispensable choice in high-hazard workplaces, where such risks are a daily reality. It is considered the gold standard for heavy-duty protection.

Meeting Safety and Compliance Standards

Employers in hazardous industries are often required by regulations, such as those guided by OSHA, to provide personal protective equipment (PPE).

Steel toe boots are a foundational component of PPE programs, ensuring that companies meet their legal and ethical obligations to protect their workers.

Durability and Cost-Effectiveness

Steel is an inherently durable material, leading to a long service life for the boots. Furthermore, steel is generally less expensive to manufacture compared to composite materials.

This combination of durability and cost-effectiveness makes steel toe boots a practical and reliable choice for outfitting large teams.

Key Environments Demanding Steel Toe Boots

While the principle is clear, specific work environments illustrate the need for this level of protection perfectly.

Construction and Manufacturing Sites

These environments are characterized by heavy materials, large machinery, and the constant risk of falling tools or components. Steel toe boots provide the necessary defense against these immediate and severe impact threats.

Warehousing and Logistics

The movement of heavy pallets, the operation of forklifts, and the potential for falling stacked goods create significant foot hazards. Steel toes are essential for protecting against crushing injuries from rolling equipment and heavy loads.

Workspaces with Sharp Objects

In addition to impact, many industrial sites have risks from sharp materials like metal scraps or glass. The robust nature of steel toe footwear provides a durable barrier against punctures and cuts.

Understanding the Trade-offs

No safety solution is without its compromises. Acknowledging the drawbacks of steel is key to making the best choice.

The Issue of Weight

Steel is the heaviest material used for safety toe caps. Over a long shift, this added weight can contribute to foot fatigue. Modern ergonomic designs help mitigate this, but the weight remains a factor compared to lighter alternatives.

Thermal Conductivity

Metal is a poor insulator. Steel toe boots will conduct cold in winter and heat in summer, which can be a significant comfort issue in extreme climates. This is a critical factor to consider for outdoor or non-climate-controlled work.

The Advantage of a Thinner Profile

Contrary to common belief, steel's strength allows its toe caps to be thinner than composite alternatives that require more bulk to achieve a similar impact rating. This can result in a less bulky, more streamlined boot profile.

Making the Right Choice for Your Goal

To select the appropriate protection, align the boot's characteristics with your primary operational needs.

- If your primary focus is maximum impact protection: Steel toe boots are the unequivocal standard for environments with heavy machinery or a high risk of falling objects.

- If your primary focus is all-day comfort in moderate-risk areas: You must weigh steel's heaviness against the specific level of hazard; lighter composite alternatives may be suitable where impact risks are lower.

- If your primary focus is working in extreme temperatures: Be aware that steel's thermal conductivity is a significant drawback, and composite toes may offer superior insulation and comfort.

Ultimately, a thorough risk assessment of your specific work environment is the only way to ensure true foot safety.

Summary Table:

| Key Consideration | Steel Toe Boots |

|---|---|

| Primary Use Case | High-risk environments with heavy falling objects or rolling equipment |

| Key Advantage | Unmatched impact and compression resistance |

| Ideal Industries | Construction, Manufacturing, Warehousing, Logistics |

| Main Trade-off | Heavier weight and higher thermal conductivity |

Need reliable safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of steel toe and safety boots for distributors, brand owners, and bulk clients. We ensure your workforce has durable, compliant, and cost-effective protection tailored to the demands of construction, manufacturing, and logistics.

Contact us today to discuss your bulk footwear needs and get a quote!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

People Also Ask

- What are the recommended uses for steel toe safety shoes? Essential Protection for High-Risk Industries

- What materials are used for toe protection in work boots? Steel vs. Composite Toe Cap Guide

- Do steel toes perform as well as composite toes in extreme weather? A Guide to Thermal Regulation

- What are the pros and cons of steel safety toes? Weighing Protection vs. Comfort & Conductivity

- What are the key features of women's safety toe work boots? Essential Protection for Hazardous Work

- How can you quickly break in steel toe boots? A Fast, Pain-Free Method for Comfort

- What are the 5 main protections offered by steel toe boots? A Guide to Workplace Foot Safety

- What is the first consideration for making steel toe boots more comfortable? Start with the Perfect Fit