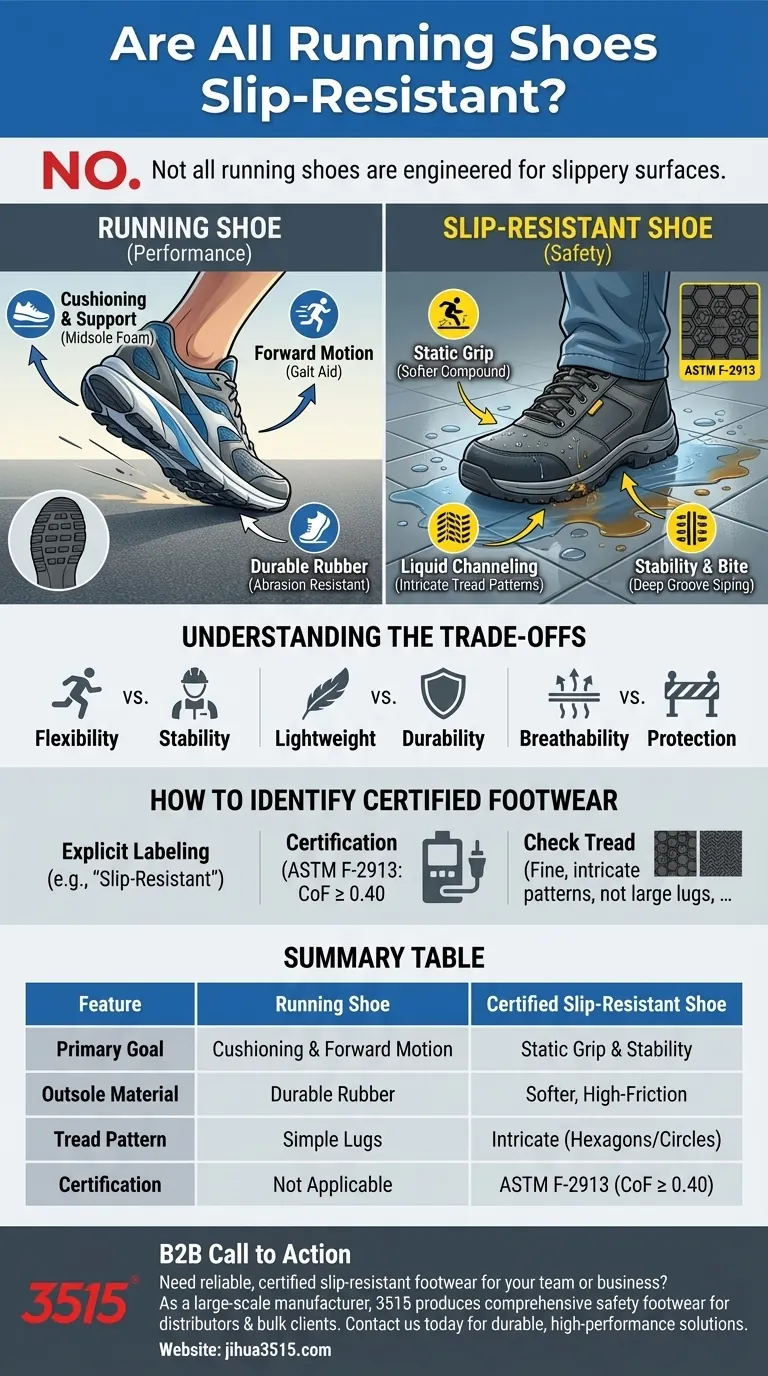

No, not all running shoes are slip-resistant. While most running shoes provide some traction, they are not engineered to the same standards as footwear specifically designed for hazardous, slippery surfaces. True slip resistance is a dedicated safety feature that depends on a shoe's specific outsole material, tread pattern, and official certification.

The core misunderstanding arises from conflating general traction with certified slip resistance. Running shoes are designed for forward motion and cushioning during athletic activity, whereas slip-resistant shoes are engineered primarily for static grip and stability in workplace environments where oils, water, and other liquids are present.

What Defines a Running Shoe's Design?

Running shoes are highly specialized equipment, but their specialization is performance, not occupational safety. Their design prioritizes factors that aid a runner's gait and comfort over miles of use.

The Priority: Cushioning and Support

The primary goal of a running shoe is to absorb impact and provide support for a specific foot type and running style. The midsole foam, heel counter, and overall shape are built to reduce stress on the joints during repetitive forward motion.

The Role of the Outsole

The outsole of a standard running shoe is made of durable rubber designed to withstand abrasion from pavement or trails. While it provides the traction needed for running, its design is not optimized to prevent slips on slick, flat surfaces like a wet kitchen floor.

The Anatomy of a Truly Slip-Resistant Shoe

Slip-resistant shoes are built from the ground up with one primary goal: maximizing grip on hazardous surfaces. This is achieved through three key design features.

The Outsole Material

These shoes use softer rubber compounds that offer a better grip on smooth, wet surfaces. This material is engineered to maintain its friction coefficient even when contaminants like water or oil are introduced.

The Tread Pattern

Instead of simple lugs for running, slip-resistant outsoles feature intricate, often circular or hexagonal, tread patterns. These patterns are designed to channel liquids out from under the shoe, allowing the sole to make direct contact with the surface.

The Groove Depth

Deeper and more numerous grooves (siping) create many small edges that bite into the surface. This significantly increases the contact area and friction, providing a much more secure footing than a typical running shoe.

Understanding the Trade-offs

Choosing between a running shoe and a slip-resistant shoe involves clear trade-offs in performance, comfort, and safety. They are fundamentally different tools for different jobs.

Flexibility vs. Stability

Running shoes are designed to be flexible to accommodate the natural movement of the foot. Certified slip-resistant shoes are often more rigid and sturdy, providing a stable platform that is less about athletic performance and more about standing and walking securely.

Lightweight vs. Durability

Running shoe manufacturers strive to reduce weight for better performance. Slip-resistant shoes, especially those for work environments, are built with thick, durable materials and sometimes reinforced toes to withstand the rigors of demanding jobs.

Breathability vs. Protection

Many running shoes feature breathable mesh uppers to manage heat. Slip-resistant work shoes often have water-resistant or synthetic leather uppers to protect the foot from spills and chemicals, sacrificing some breathability for safety.

How to Identify Certified Slip-Resistant Footwear

You cannot determine if a shoe is truly slip-resistant by looks alone. Verification requires checking for specific indicators and certifications that prove the shoe has been tested for safety.

Look for Explicit Labeling

The most reliable sign is a clear label from the manufacturer stating the shoe is "slip-resistant." This indicates the shoe was designed and marketed specifically for this purpose.

Understand the Certification

In the United States, look for shoes tested under ASTM F-2913 standards. This certification means the shoe has passed standardized tests on various surfaces, often requiring a coefficient of friction of .40 or higher to be considered effective.

Check the Tread Design

While not a substitute for certification, you can visually inspect the outsole. Look for the characteristic fine, intricate patterns designed to disperse liquid, rather than the larger, simpler lugs found on most running shoes.

Making the Right Choice for Your Needs

Selecting the correct footwear is essential for both performance and safety. Your primary activity dictates which features are most important.

- If your primary focus is athletic running: Choose a shoe based on your gait, cushioning needs, and typical running surface (road, track, or trail).

- If your primary focus is safety in a work environment (e.g., kitchen, hospital): You must select a shoe that is explicitly labeled and certified as slip-resistant.

- If your primary focus is running in wet or icy conditions: Look for dedicated trail running shoes with aggressive, deep lugs designed for grip on uneven, slippery terrain.

Choosing the right shoe is about matching its specific engineering to your intended environment.

Summary Table:

| Feature | Running Shoe | Certified Slip-Resistant Shoe |

|---|---|---|

| Primary Design Goal | Cushioning & Forward Motion | Static Grip & Stability on Wet/Slick Surfaces |

| Outsole Material | Durable, Abrasion-Resistant Rubber | Softer, High-Friction Rubber Compound |

| Tread Pattern | Simple Lugs for Forward Traction | Intricate Patterns (Hexagons/Circles) to Channel Liquids |

| Key Standard/Certification | Not Applicable | ASTM F-2913 (Coefficient of Friction ≥ 0.40) |

Need reliable, certified slip-resistant footwear for your team or business?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of certified slip-resistant shoes and boots, engineered with the precise outsole materials and tread patterns for maximum safety in demanding environments.

Contact us today to discuss your specific needs and discover how we can provide durable, high-performance safety solutions for your customers.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- What is the significance of high-performance non-slip outsoles? Enhance Stability for Balance & Sensory Challenges

- How do men's work shoes provide protection from electrical hazards? Insulate Yourself from Live Circuits

- What are the key features to look for in work shoes designed for standing all day? A Guide to All-Day Comfort

- Do anti-slip shoes offer arch support? Yes, for safety and all-day comfort.

- How does wearing comprehensive safety apparel, including anti-slip boots, mitigate risks in Crude Palm Oil (CPO) storage tank areas? Ensure Operator Safety & Compliance.

- What is a temporary solution for making shoes non-slip? Quick Fixes for Immediate Grip

- What is the role of professional-grade anti-slip footwear in gait training? Enhance Safety & Stability in Rehab

- What are the five key features that define non-slip shoes? Your Guide to Workplace Safety